Electrohydraulic automatic clutch actuating mechanism

An automatic clutch and actuator technology, applied in non-mechanical drive clutches, clutches, mechanical equipment, etc., can solve the problems of large motor drive power loss, uncompact structure, large volume, etc. Small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] An electro-hydraulic automatic clutch actuator proposed by the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. Advantages and features of the present invention will be apparent from the following description and claims. It should be noted that all the drawings are in a very simplified form and use imprecise scales, and are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention.

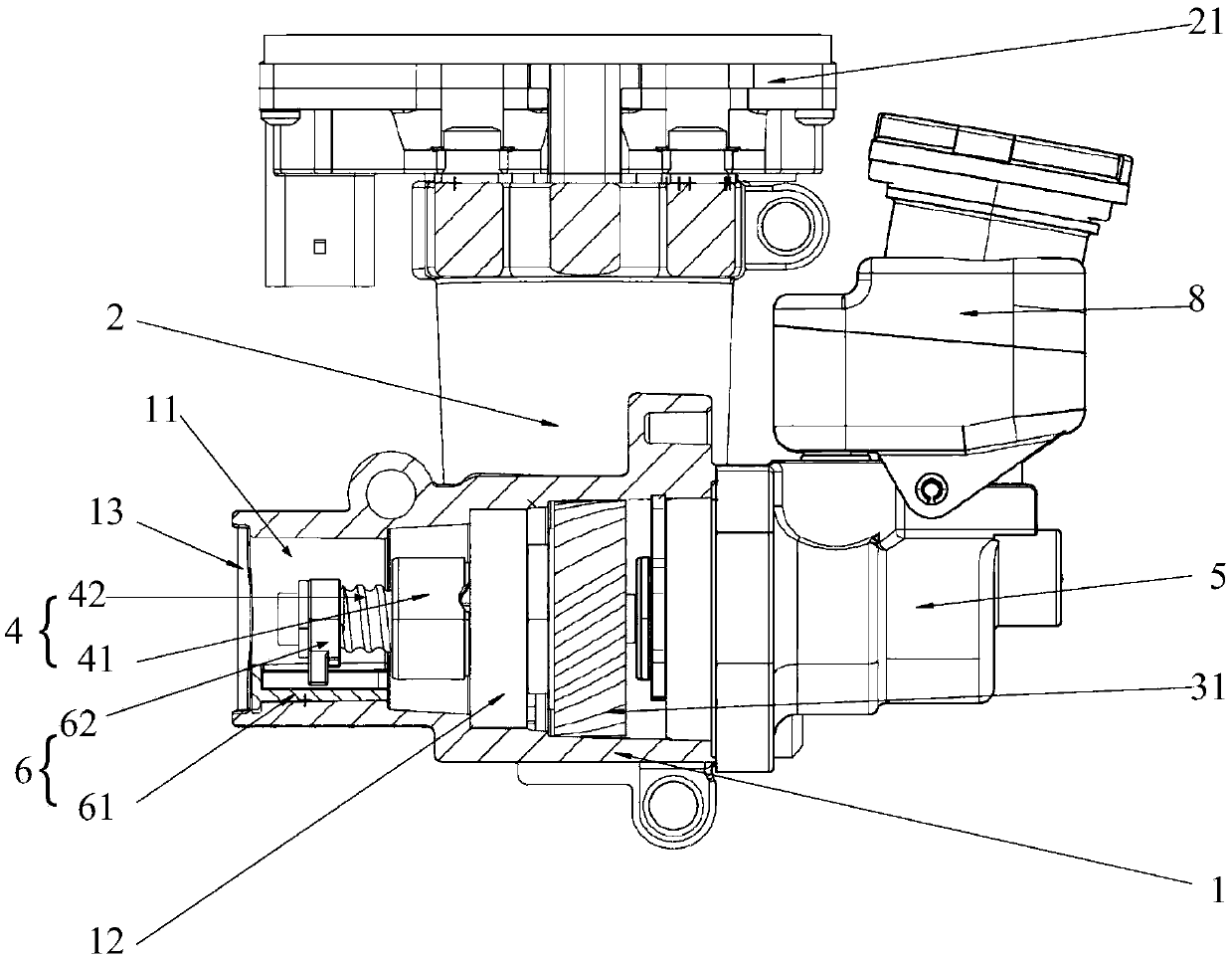

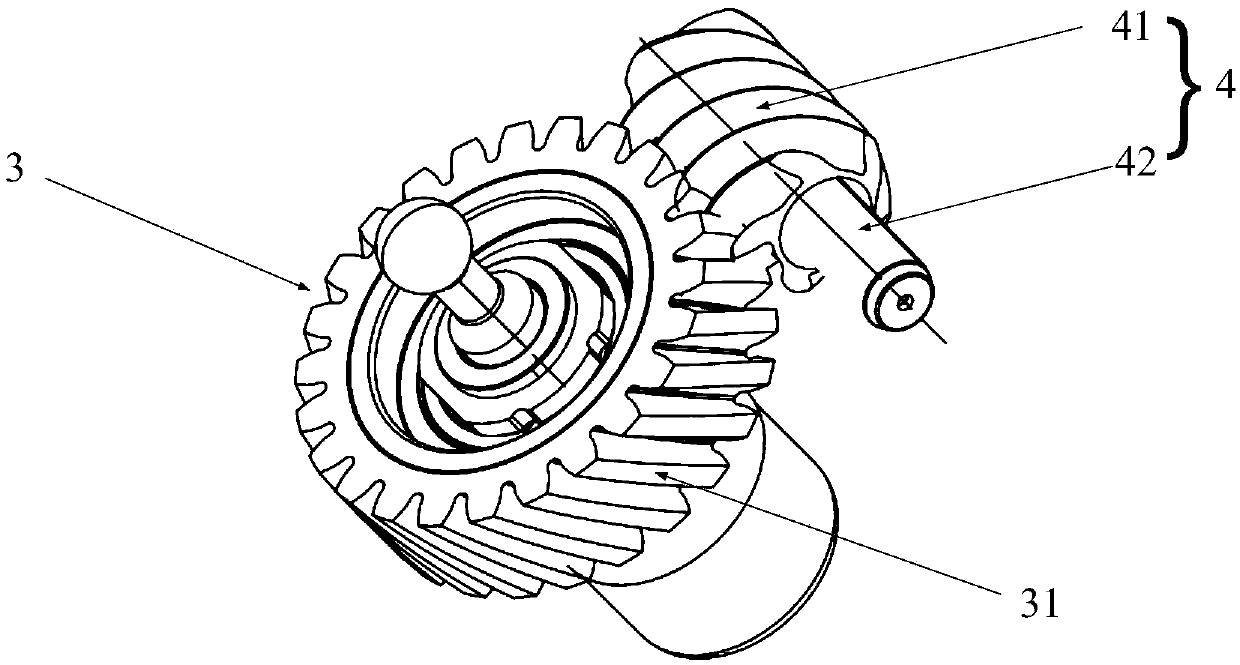

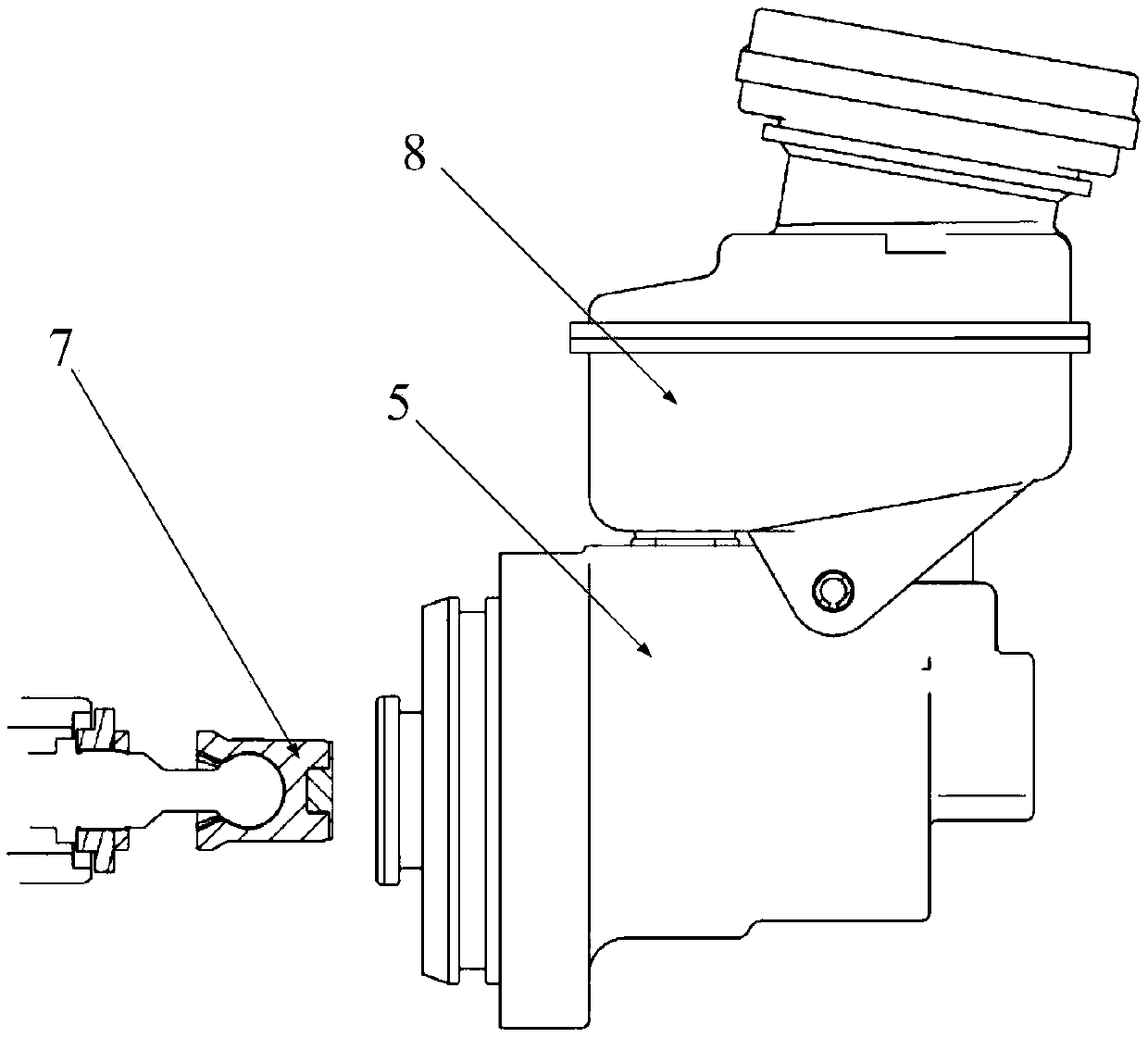

[0026] figure 1 It is a schematic diagram of an electro-hydraulic automatic clutch actuator provided by an embodiment of the present invention. Please refer to figure 1 , an electro-hydraulic automatic clutch actuator, including a housing 1, a motor 2, a worm gear 3, a ball screw 4, and a hydraulic master cylinder 5; the housing 1 has an inner cavity 11 penetrating along a first direction, so One end of the inner chamber 11 is sealed by a plug cover 13,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com