Weak current cable connector

A technology of electric cables and connectors, which is applied in the connection mechanism field of weak electric cable wiring, which can solve the problems of transmission signal attenuation, a large number of consumables, and small contact area, and achieve the effects of no distortion of the picture, energy saving, and firm connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

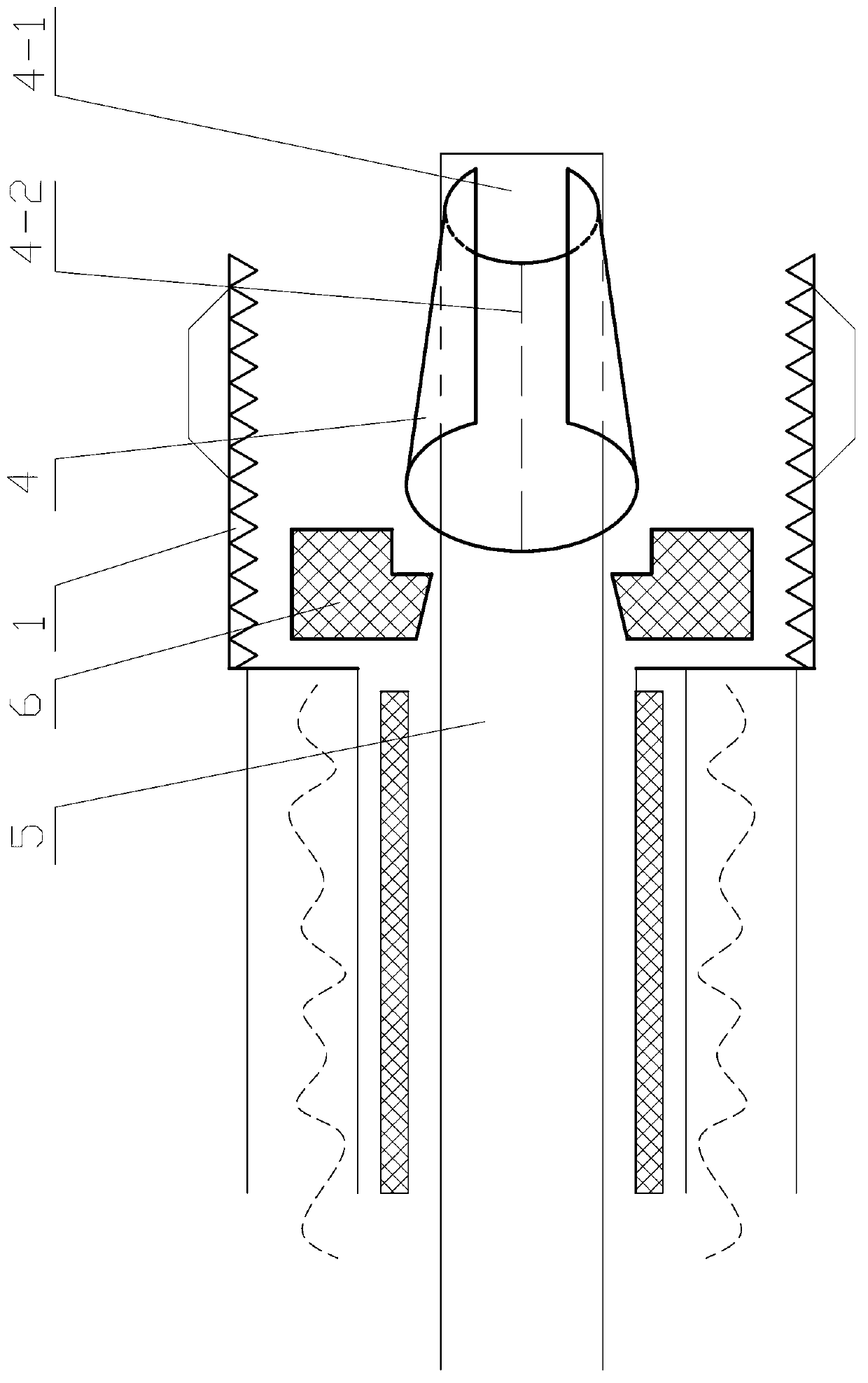

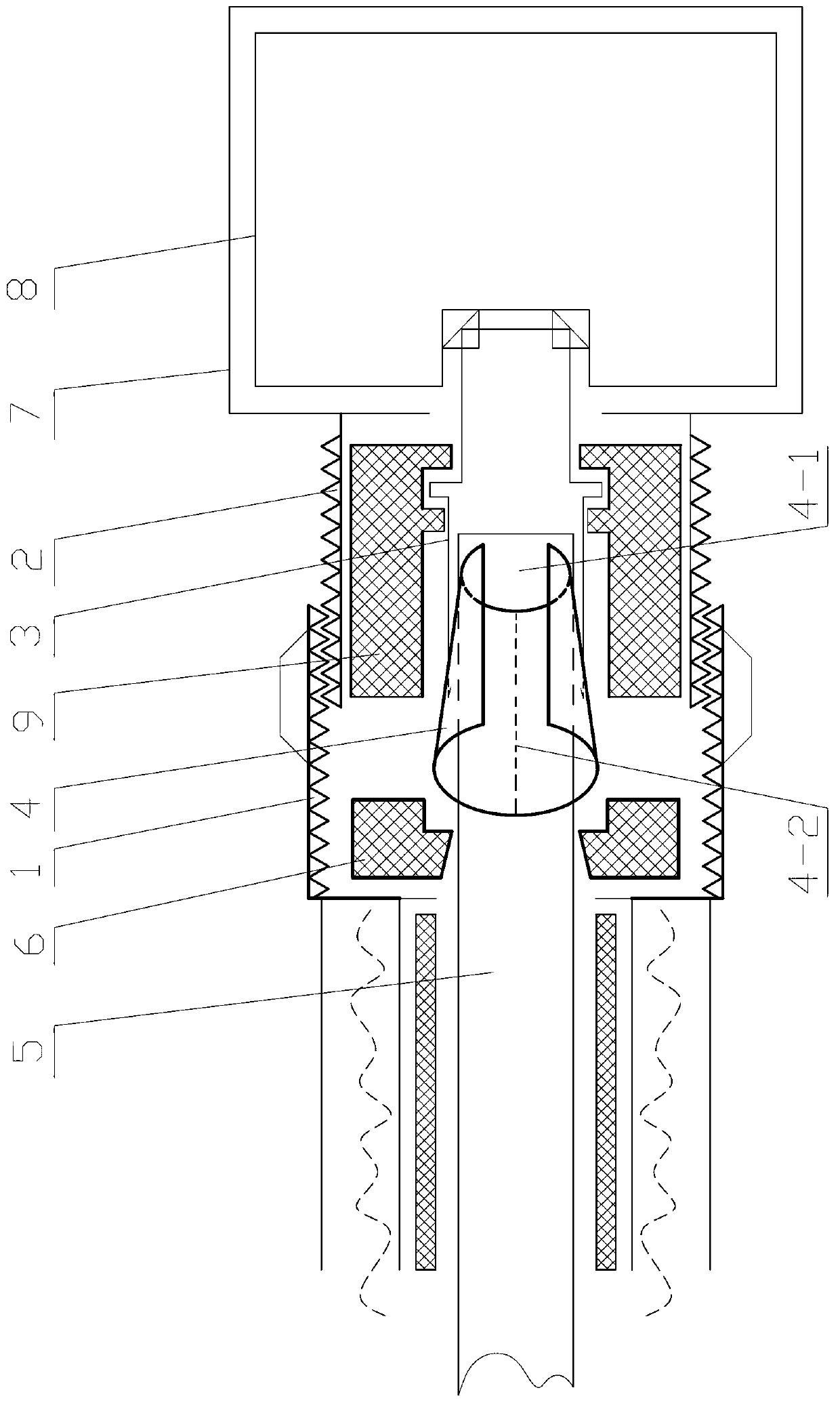

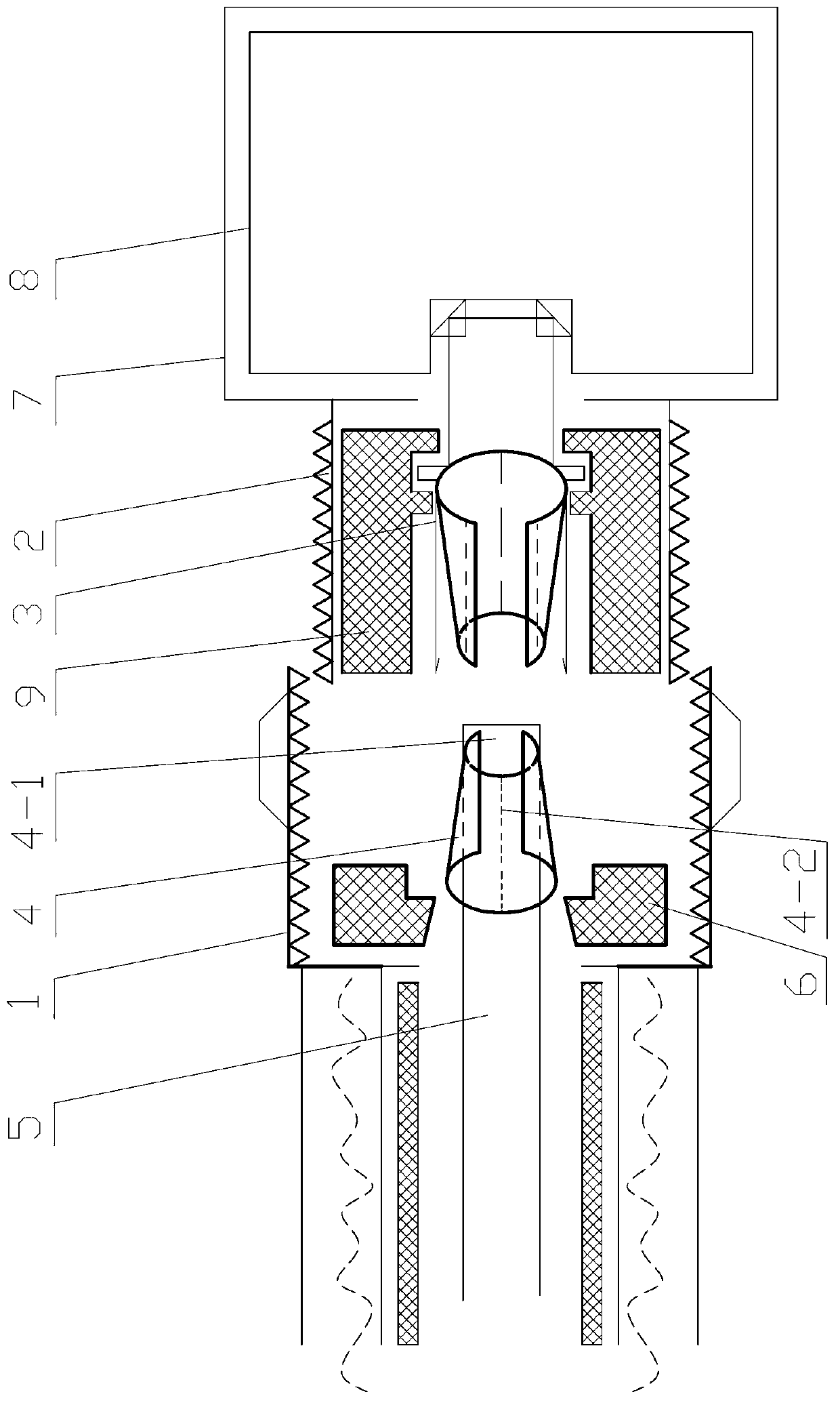

[0034] A number of technical solutions of the present invention will be further described below in conjunction with the accompanying drawings:

[0035] 1. The weak current cable connector of the present invention includes a screw sleeve 1 and a clamping part locked by the screw sleeve 1. The clamping part is a conductive tapered shrink sleeve 4, and a conductive tapered shrink sleeve 4 is provided with a The axial shrinkage groove 4-1 is radially symmetrical with the shrinkage groove 4-1, and an axial shrinkage deformation seam 4-2 is also provided on the conductive tapered shrink sleeve 4, and the large cone of the conductive tapered shrink sleeve 4 The thickness of the head end is greater than or equal to the thickness of the small cone head end; the conductive tapered shrink sleeve 4 is coaxially arranged in the screw sleeve 1, and the sleeve opening of the screw sleeve 1 corresponding to the large cone head end of the conductive tapered shrink sleeve 4 is closed. The close...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com