Method for producing pressurized liquefied natural gas, and production system used in same

A pressurized liquefaction and natural gas technology, applied in the field of manufacturing PLNG and manufacturing systems, can solve problems such as unfavorable liquefied natural gas manufacturing systems, and achieve the effects of shortening the investment recovery period, reducing construction costs, and reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0085] Exemplary embodiments of the present invention will be described in detail below with reference to the accompanying drawings. The following embodiments can also be changed into various forms, and the scope of the present invention is not limited to the following embodiments.

[0086] Throughout the disclosure, like reference numerals refer to like parts throughout the drawings and embodiments of the present invention.

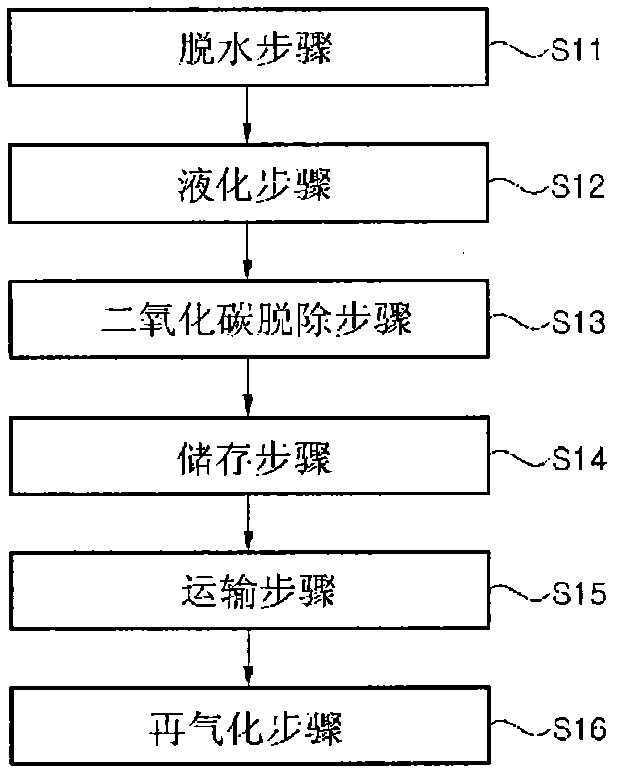

[0087] figure 1 is a flowchart showing a pressurized liquefied natural gas production method according to the present invention.

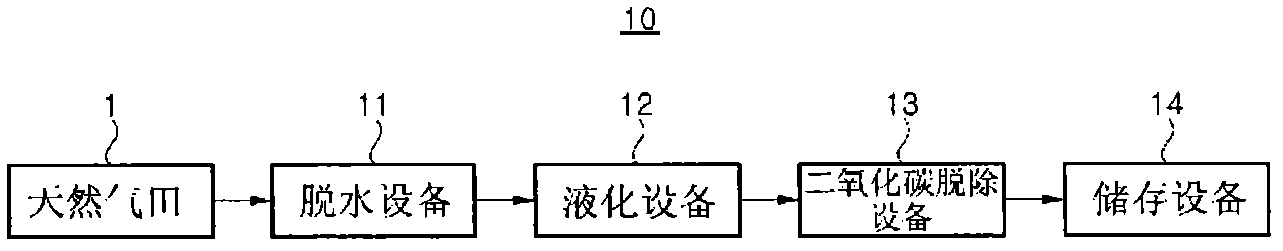

[0088] Such as figure 1 As shown in , the pressurized liquefied natural gas production method according to the present invention produces pressurized liquefied natural gas by: removing water from natural gas without removing acid gas from natural gas supplied from the natural gas field 1; and The process of liquefying natural gas by pressurizing and cooling without fractionating natural gas into natural gas liquid (NGL). ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com