Lupulus solid drink and preparation method thereof

A technology of solid beverage and hops, applied in food preparation, application, food science, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

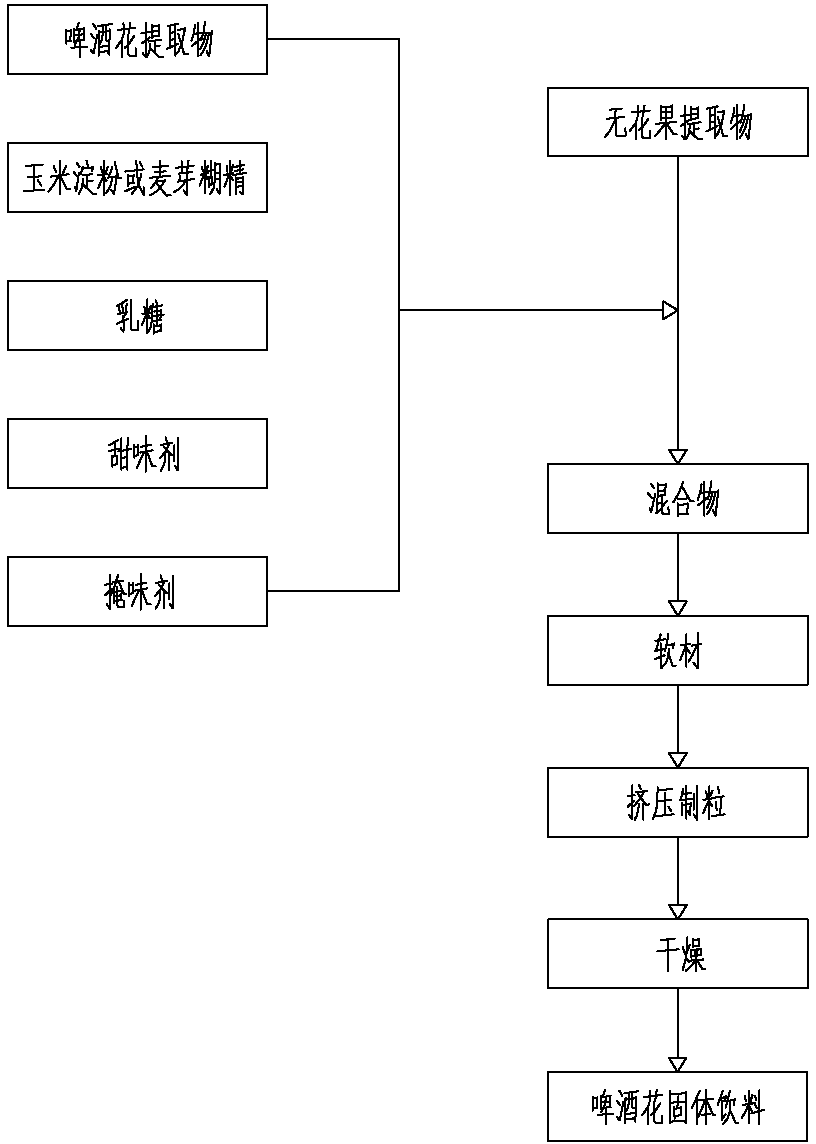

[0030] Embodiment 1, the hop solid beverage, the raw material contains 2.58 to 7.74 parts of hop extract, 10.67 to 64.04 parts of fig extract, 1.32 to 172.3 parts of corn starch or maltodextrin, and 1.32 to 172.3 parts of lactose in parts by weight. 0.001 to 0.24 parts of sweetener, 0.02 to 0.58 parts of taste masking agent, and 0.21 to 72 mL of ethanol with a volume percentage of 75% to 95%; the hop solid drink is obtained by the following steps: the first step, the The required amount of hop extract, fig extract, corn starch or maltodextrin, lactose, sweetener and taste masking agent are pulverized and mixed into a mixed material, and the required amount of ethanol is added to the mixed material to moisten the mixed material and The soft material is bonded together to obtain a soft material; in the second step, the soft material is extruded and granulated through a 10-mesh sieve to a 20-mesh sieve, and then dried at a temperature of 50°C to 60°C for 1 hour to 3 hours to obt...

Embodiment 2

[0031] Example 2, the hop solid beverage, the raw material contains 2.58 or 7.74 parts of hop extract, 10.67 or 64.04 parts of fig extract, 1.32 or 172.3 parts of corn starch or maltodextrin, and 1.32 or 172.3 parts of lactose by weight. part, 0.001 part or 0.24 part of sweetener, 0.02 part or 0.58 part of taste masking agent, 0.21 mL or 72 mL of ethanol with a volume percentage of 75% or 95%; The required amount of hop extract, fig extract, corn starch or maltodextrin, lactose, sweetener and taste masking agent are pulverized and mixed into a mixed material, and the required amount of ethanol is added to the mixed material to moisten the mixed material and The soft material is bonded together to obtain a soft material; in the second step, the soft material is extruded and granulated through a 10-mesh or 20-mesh sieve, and dried at a temperature of 50°C or 60°C for 1 hour or 3 hours after granulation to obtain a hop solid beverage. The hop solid beverage is packed into bags,...

Embodiment 3

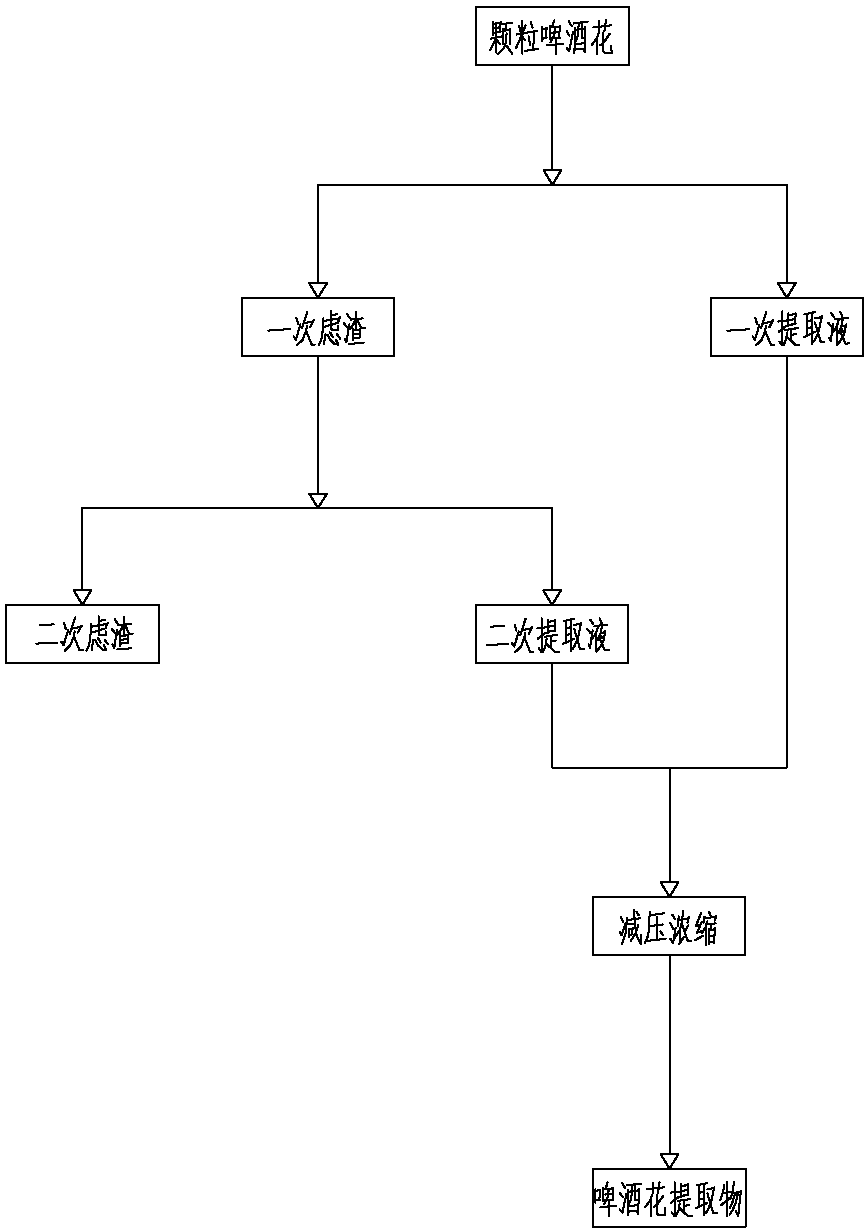

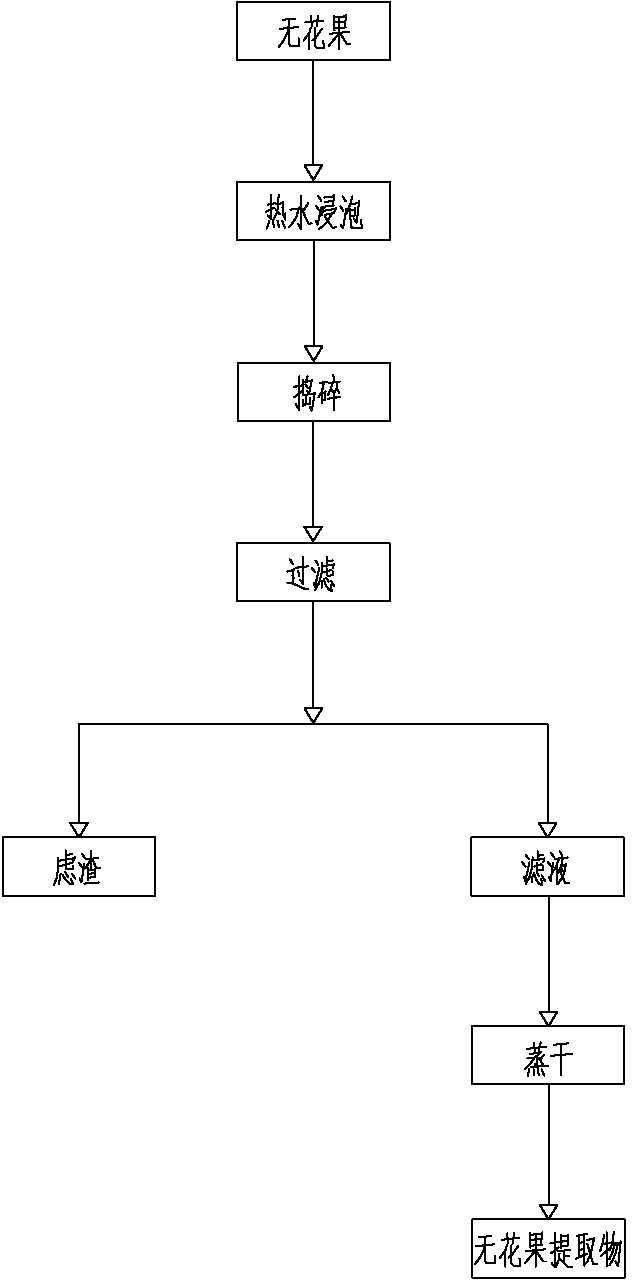

[0032] Embodiment 3, as the optimization of the above-mentioned embodiment, the hop extract of embodiment 3 is obtained according to the following steps: the first step, the granular hops are pulverized and then added to water with 6 to 30 times the volume of the granular hops to carry out a reflux extraction , the temperature of one-time reflux extraction is 80°C to 90°C, the time of one-time reflux extraction is 0.5 hours to 3 hours, and one-time reflux extraction is filtered to obtain one-time extract and one-time filter residue; the second step is to add 6 to 30 times of Secondary reflux extraction is carried out in water with the volume of granular hops, the secondary reflux extraction temperature is 80°C to 90°C, the secondary reflux extraction time is 0.5 hours to 3 hours, and the secondary reflux extraction is filtered to obtain the secondary extract and the secondary reflux extraction. Filter residue; in the third step, the primary extract and the secondary extract a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Weight | aaaaa | aaaaa |

| Maximum tolerated dose | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com