Heat-punching composite mould

A hot stamping die and hot stamping technology, applied in the field of hot stamping, can solve the problems of not considering the influence of cooling pipes and large limitations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

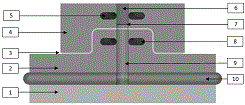

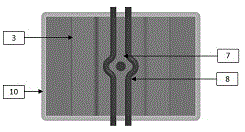

[0016] exist figure 1 In the front view of the schematic diagram of the hot stamping composite die shown, a hot stamping composite die consists of a lower mold base (1), a forming punch (2), a hot stamping part (3), a forming die (4), and a forming die Die cooling system (5), punching die (6), punching waste (7), forming punch cooling system (8), punching punch (9), rubber (10). The composite mold is connected with the press by the lower mold base (1), the lower mold base (1) and the forming punch (2) and the punching punch (9) transmit power through the rubber (10), and the forming punch (2) and the forming The hot stamping part (3) is molded by the mold closing of the die (4), and the holes on the hot stamping part are punched out by the punching punch (9) and the punching die (6). By passing cooling water into the forming die cooling system (5) and forming punch cooling system (8), the mold is forced to cool, so that the hot stamping composite mold can be kept within the n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com