Laminator

A film laminating machine and film technology, which is applied in the direction of lamination device, lamination auxiliary operation, lamination, etc., can solve the problems of accuracy reduction, image deviation, rotation seat 121 occupancy, etc., and achieve the effect of reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

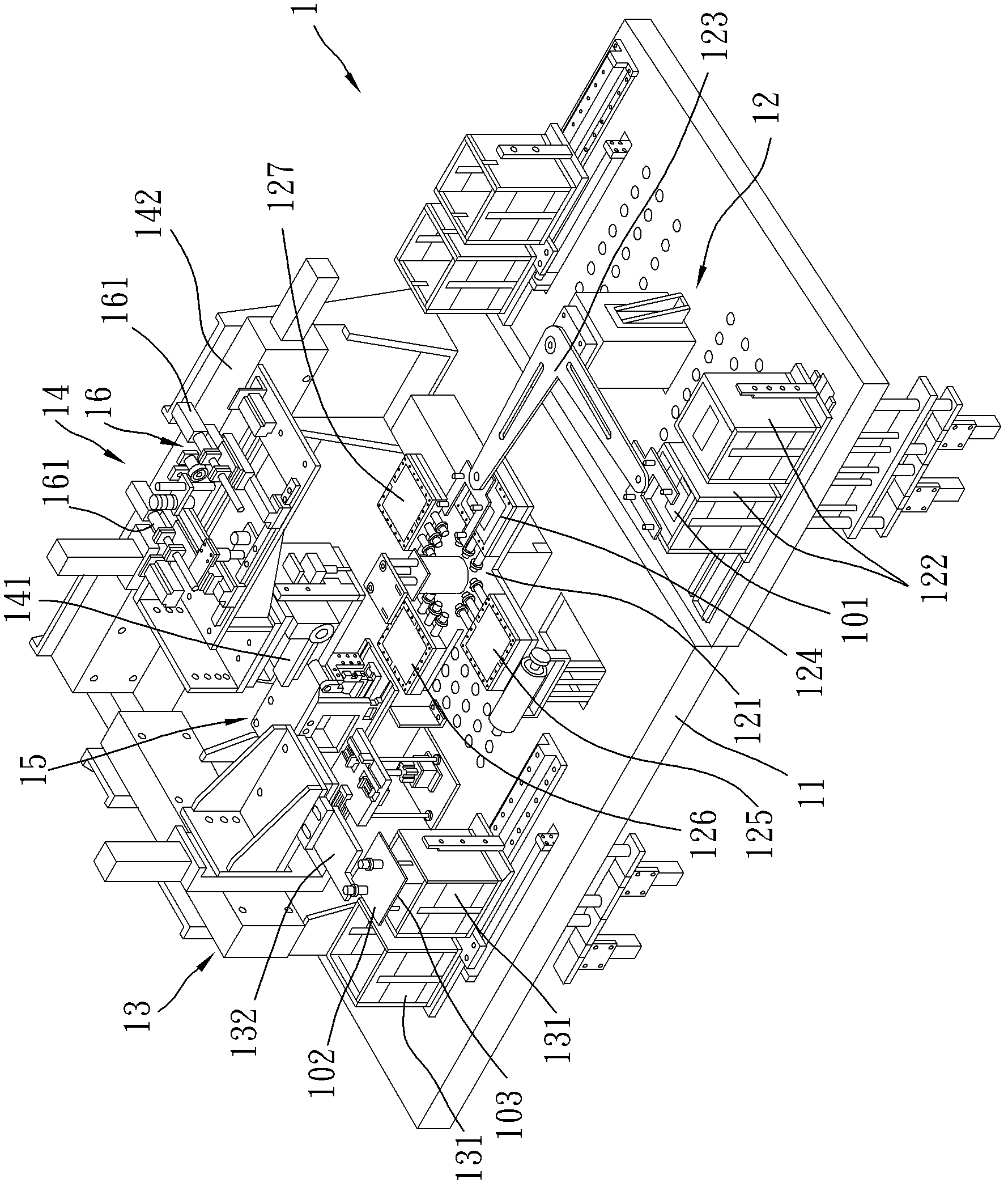

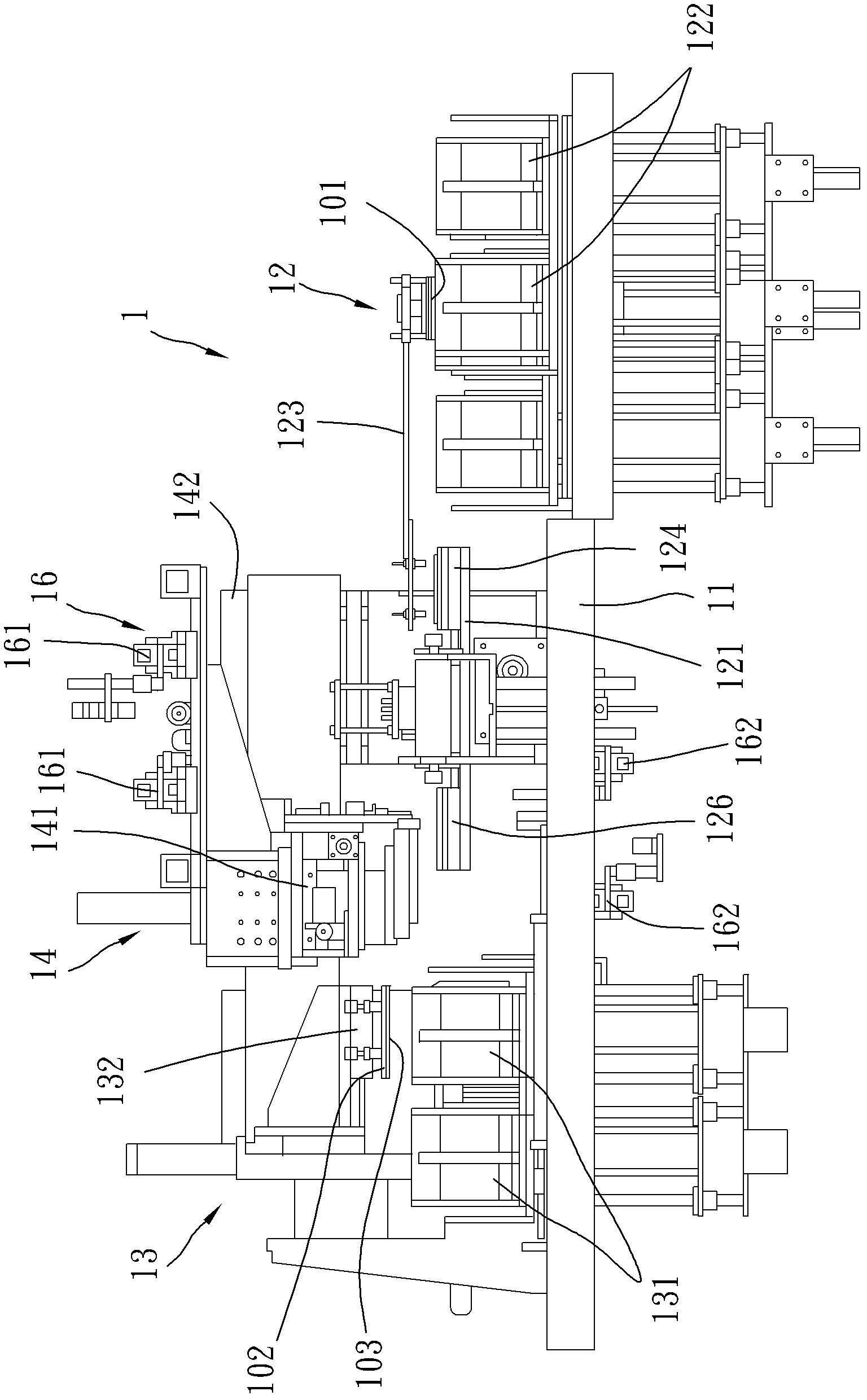

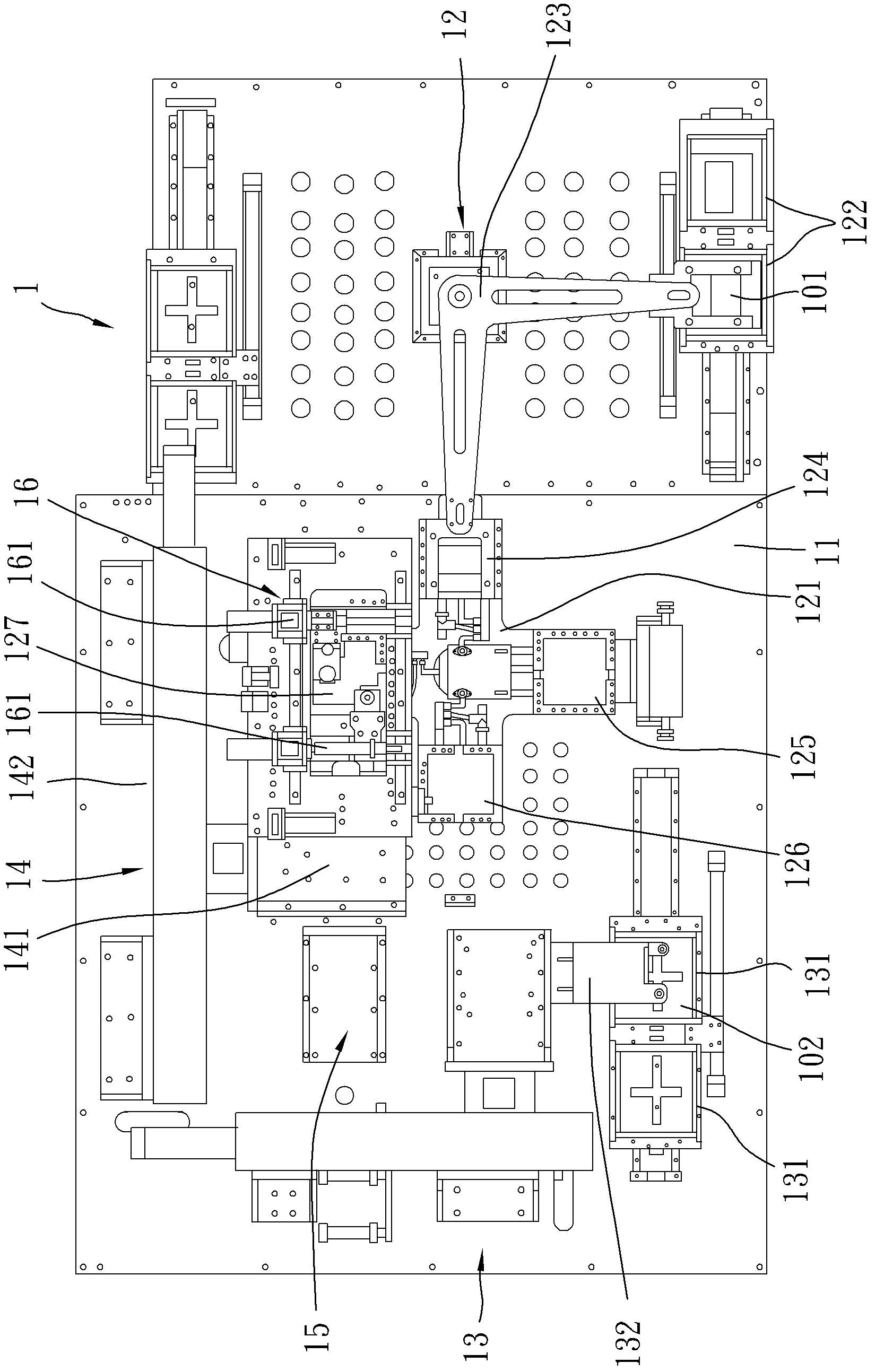

[0030] refer to Figure 4 , Figure 5 and Image 6 , a preferred embodiment of the film laminating machine of the present invention can quickly and high-yield paste multi-layer films such as touch panels, backlight modules or other optical plates. In this embodiment, a piece of first film 21 and A piece of second membrane 22 and a piece of peelable protective film 23 attached to the bottom of the second membrane 22 are used as an example for illustration, and of course the implementation is not limited thereto.

[0031] The film laminating machine includes: a machine platform 3, and a first conveying device 4, a second conveying device 5, a film-separating device 6, a third conveying device 7 and an adjusting device 8 installed on the machine platform 3 . The directions shown in the figures are used for illustration below, and of course, the implementation d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com