Composite material double-body rotor for light motor

A composite material and rotor technology, which is applied in the manufacture of stator/rotor body, magnetic circuit rotating parts, electrical components, etc., can solve the problem that the rotor cannot rotate stably, and achieve the effect of reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

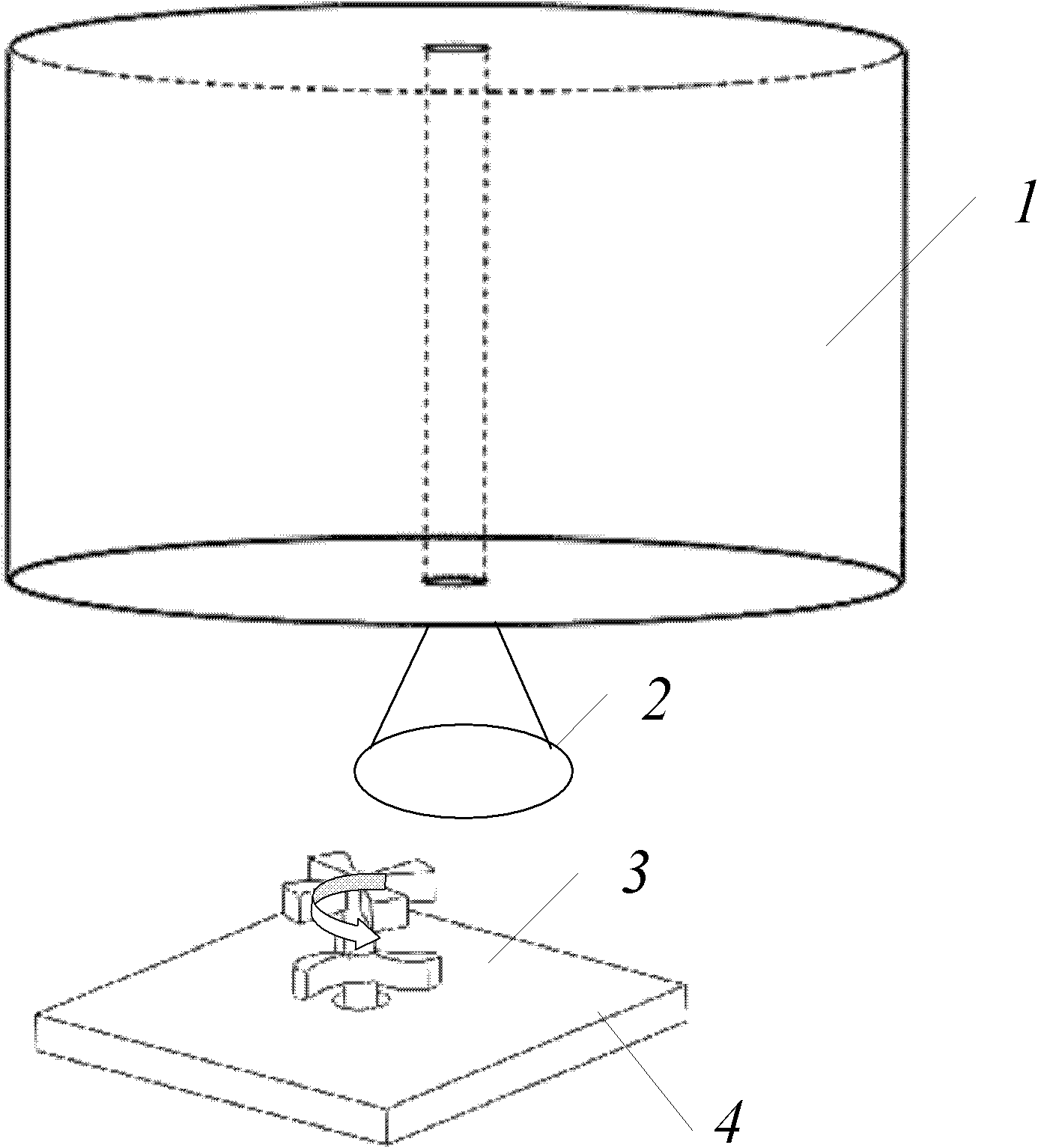

[0033] The present invention is described in more detail below in conjunction with accompanying drawing example:

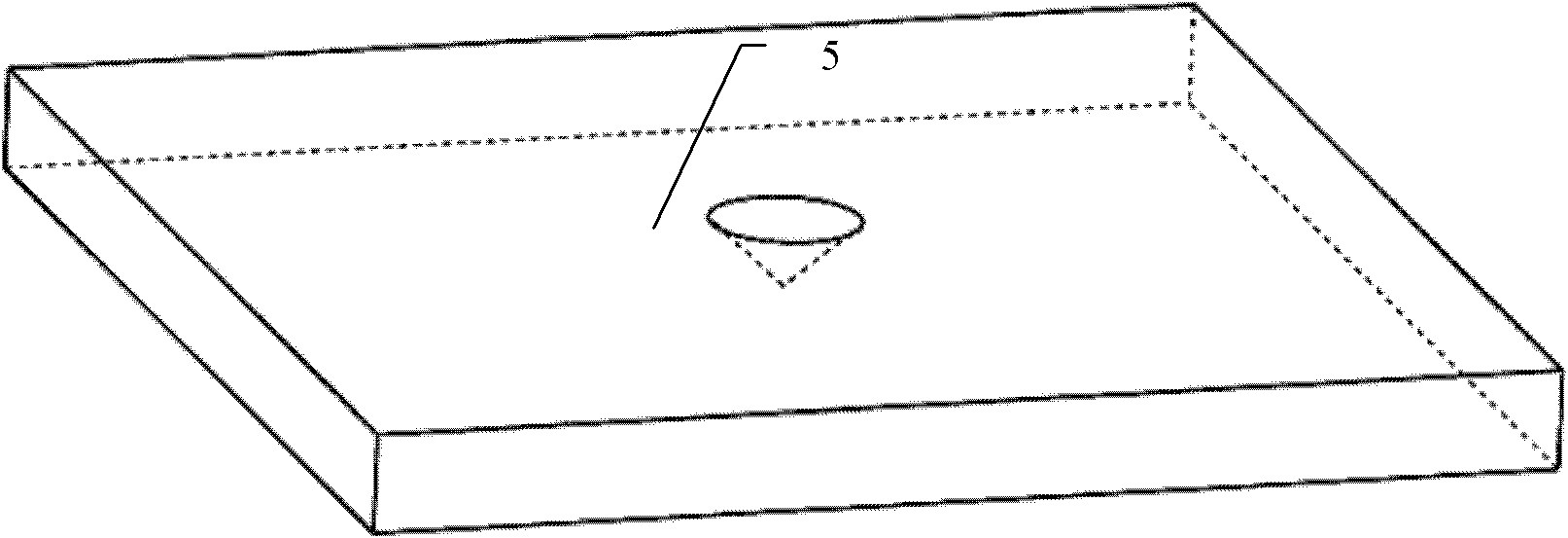

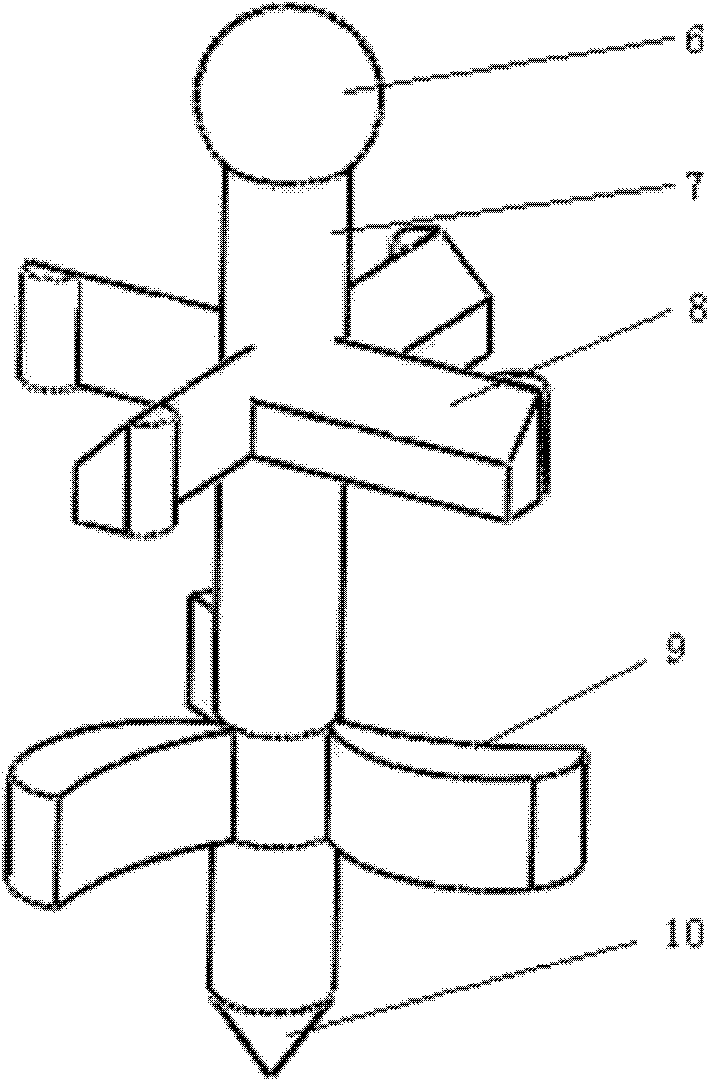

[0034] combine Figure 1-3 , the first embodiment of the composite double-body rotor for optical motors of the present invention is used when the light emitted by the light source is located directly above the rotor. The working tool layer made of large material, the optical drive layer includes the rotating shaft 7 and the upper body rotor 8, the working tool layer includes the lower rotor 9 and the pointed rotating shaft 10, the upper body rotor is located at the upper end of the rotating shaft, and the lower layer The rotor is located at the lower end of the rotating shaft, and the tip-shaped rotating shaft is connected to the lower top of the rotating shaft, and also includes a base 4, and the pointed rotating shaft is nested in a tapered small hole 5 with a diameter slightly larger than that of the rotating shaft on the base. The upper body rotor is a "windm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com