Spiral groove for medicine transportation and manufacturing method thereof

A manufacturing method and technology of spiral grooves, which are applied in the directions of transportation and packaging, slideways, etc., can solve problems such as changing the spiral angle and flow path width, polluting the environment, etc., to improve structural stability and durability, and reduce friction , the effect of prolonging the use time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

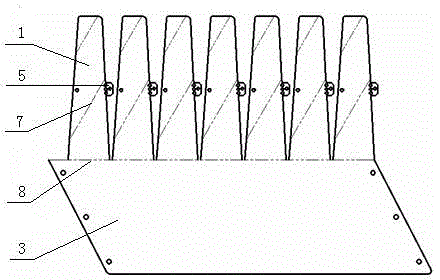

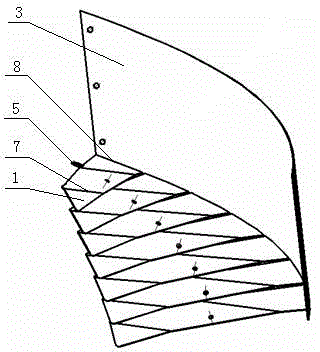

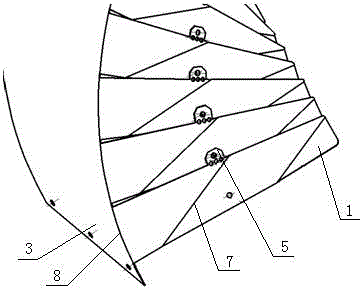

[0030] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0031] Such as Figure 7As shown, this embodiment provides a spiral groove for drug delivery, including a spiral assembly and a circular tube 2 for positioning the spiral assembly. The spiral assembly is a plurality of spiral parts stacked in a helical manner with the circular tube 2 as the center Connected in sequence, the spiral piece includes a side vertical plate 3 and several spiral pieces 1, and the spiral piece is bent to form the side vertical plate 3 and the spiral piece 1 after blanking as a whole, and the bottom surface of the spiral piece 1 Bolts 4 are all provided, and a connecting head 5 is provided on one side, and the connecting head 5 of the spiral sheet 1 is provided with an adaptive bending process hole for the bolt 4 of the adjacent spiral sheet 1 to pass through. 1. Form a helical shape around the round tube 2 in turn, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com