Frame sealing glue and preparation method thereof

A frame-sealing and coating technology, applied in adhesives, optics, instruments, etc., can solve the problems of low product yield, increased glue breakage rate, and increased impact on frame-sealing glue, so as to achieve poor glue breakage. The effect of low rate, improved yield and neat edge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

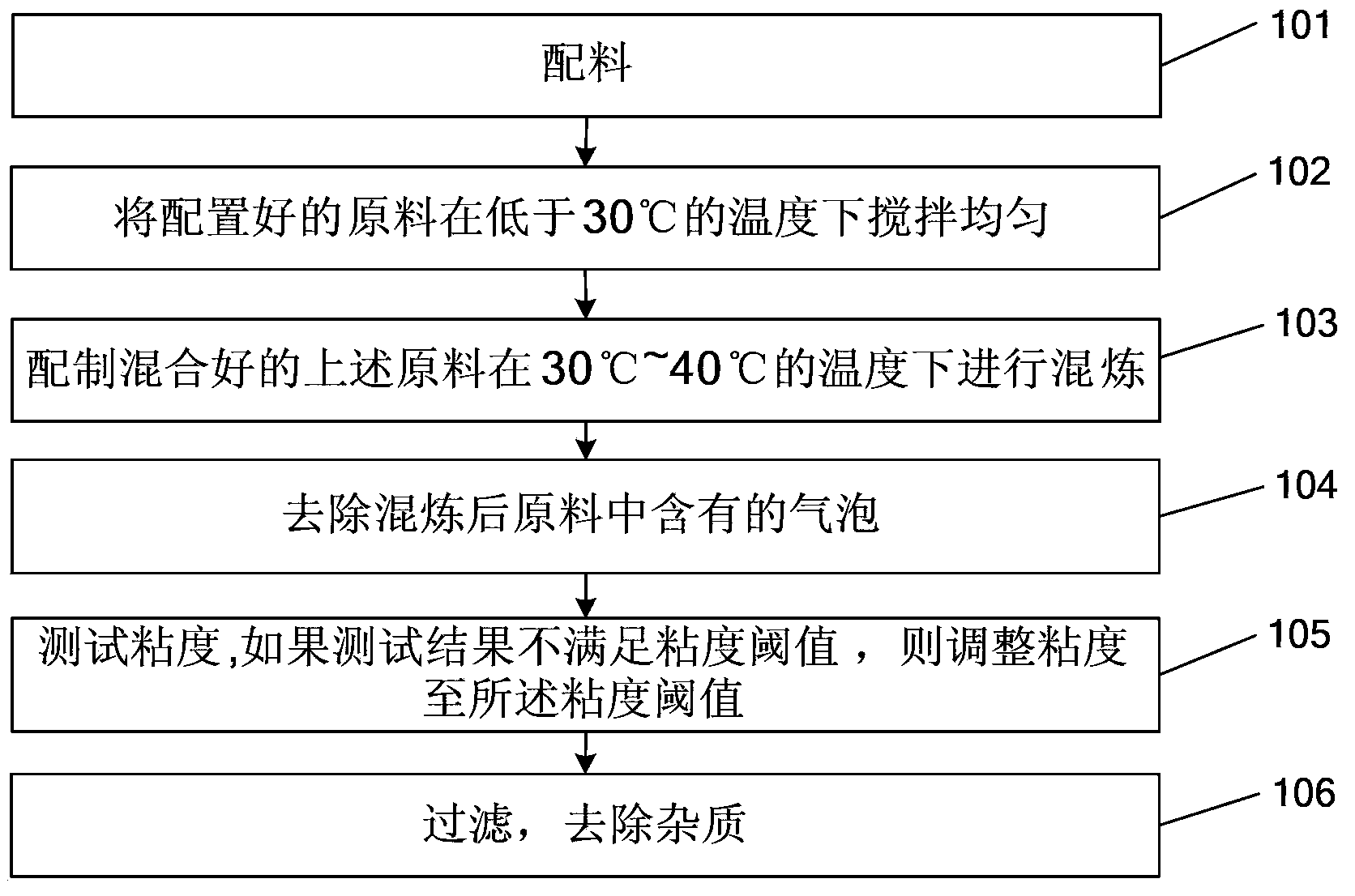

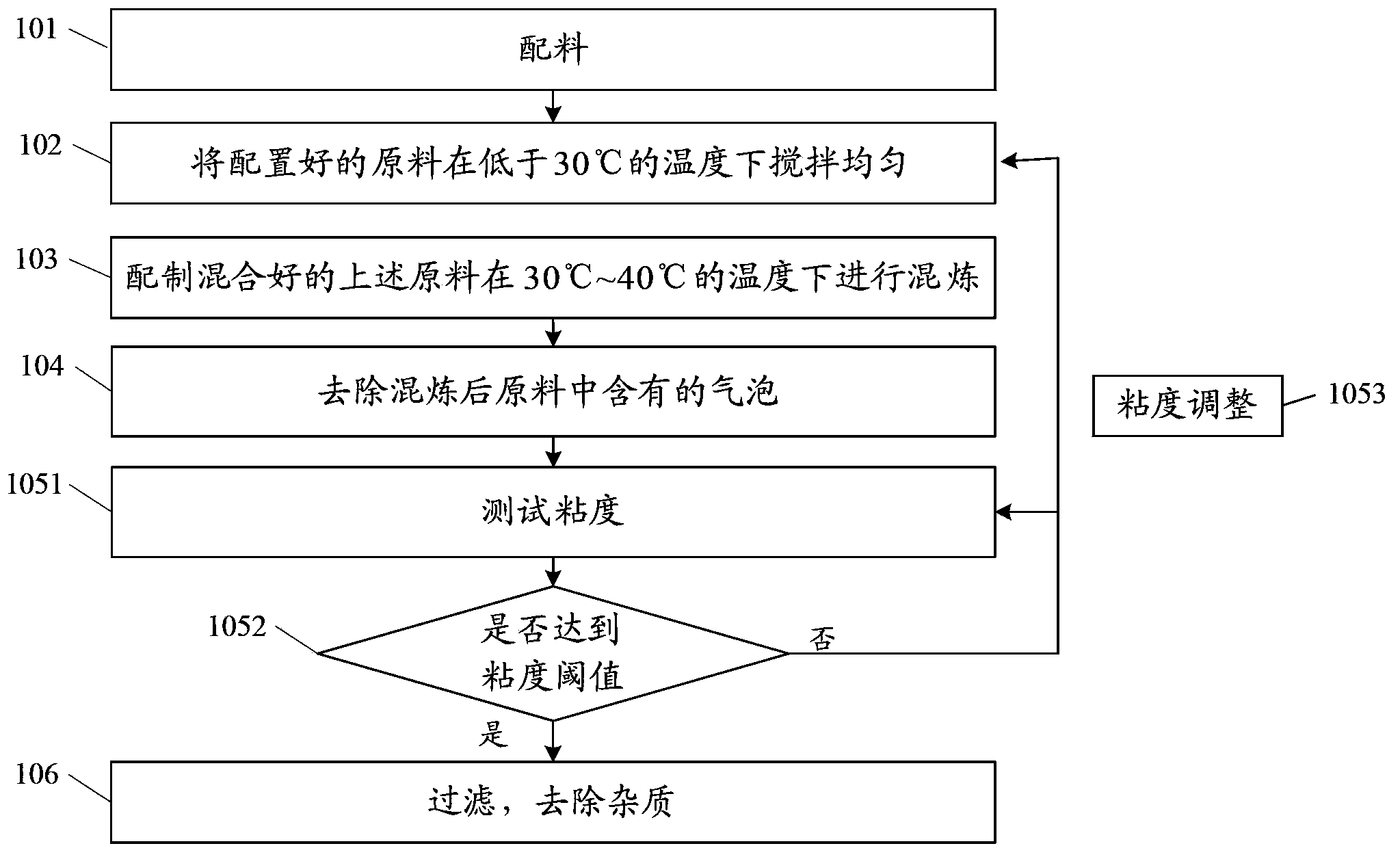

[0042] The invention provides a method for preparing a frame sealant, comprising the following steps:

[0043] The raw materials for preparing the frame sealant are mixed evenly at a temperature lower than 30°C, wherein the composition of the raw materials for the preparation of the frame sealant includes: low-viscosity epoxy acrylic photocurable resin, light Initiators, coupling agents, conventional organic fillers, conventional inorganic fillers, and nanofillers.

[0044] Wherein, the low-viscosity epoxy acrylic photocurable resin specifically refers to the epoxy acrylic photocurable resin with a viscosity of 40-80 Pa·s. The conventional organic fillers and conventional inorganic fillers are commonly used sealant ingredients, for example, the conventional organic fillers are elastic rubber balls with a diameter of 0.1um~1.0um, and the conventional inorganic fillers are elastic rubber balls with a diameter of 1.0um~2.0um of silica spheres. Generally speaking, silicon balls ...

Embodiment 1

[0050] The embodiments of the present invention provide a frame sealing adhesive with higher bonding strength, especially suitable for narrow-frame liquid crystal panels, which can improve the high yield of narrow-frame products, such as figure 1 As shown, the preparation method of the sealant is as follows, including:

[0051] Step 101, batching, the composition and proportion (mass percentage) of each raw material for preparing the sealing glue are as follows:

[0052] 60% low viscosity epoxy acrylic photocurable resin, 1% photoinitiator, 2% coupling agent, 14% conventional organic filler, 18% conventional inorganic filler, and 5% nanometer filler; Support the box with silicon spheres 1% thick.

[0053] The low-viscosity epoxy acrylic light-curing resin described in this embodiment specifically refers to the epoxy-acrylic light-curing resin with a viscosity of 40-80 Pa·s (rotation speed: 2.5 rpm), which can be prepared in advance. Preferably, the structural formula of the lo...

Embodiment 2

[0078] The embodiment of the present invention also provides another method for preparing a frame sealant and the frame sealant prepared by this method. The difference from Example 1 is that the composition and proportion (mass percentage) of the raw materials used to prepare the frame sealant are different. ,details as follows:

[0079] 68% low-viscosity epoxy acrylic photocurable resin, 1% photoinitiator, 2% coupling agent, 10% conventional organic filler, 14% conventional inorganic filler, and 5% nanometer filler.

[0080] In addition, 1% of silicon balls for supporting the thickness of the box can be added.

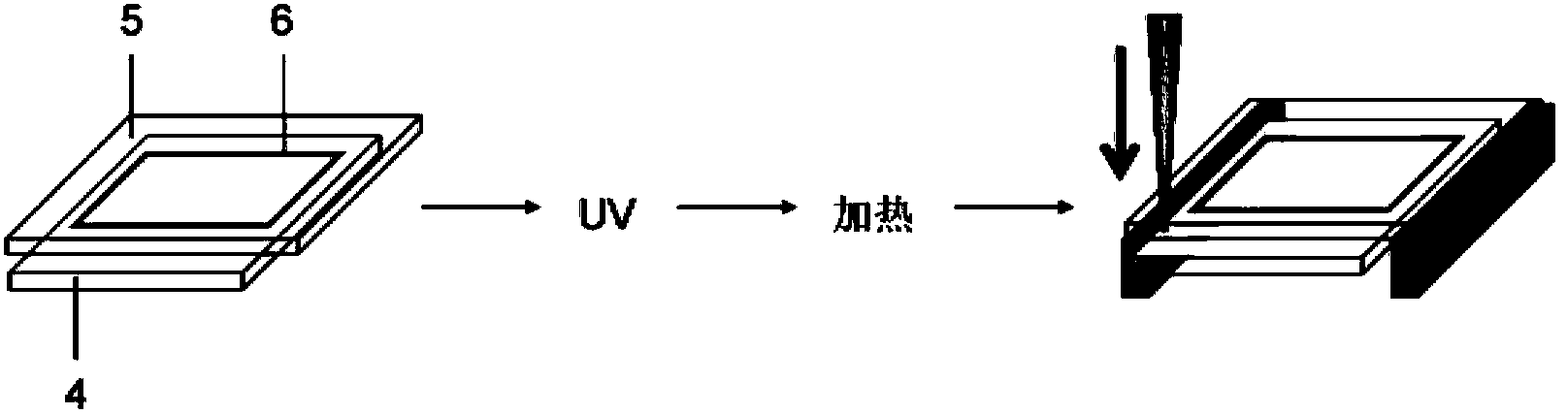

[0081] The embodiments of the present invention provide a preparation method and the frame sealant prepared according to the method. When the frame sealant is coated with thin lines, the incidence of defective glue breaking is low, the edges of the frame sealant are neat, and there is no liquid crystal puncture phenomenon, avoiding In order to cause pollution to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com