Bicolor bamboo joint composite yarn and production method thereof

A technology of slub yarn and slub, applied in the direction of yarn, spinning machine, drafting equipment, etc., can solve the problems of single style, lack of obvious characteristics, large fluctuation of product quality, etc., and achieve novel and diverse appearance and market prospects. Broad, excellent hygroscopic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

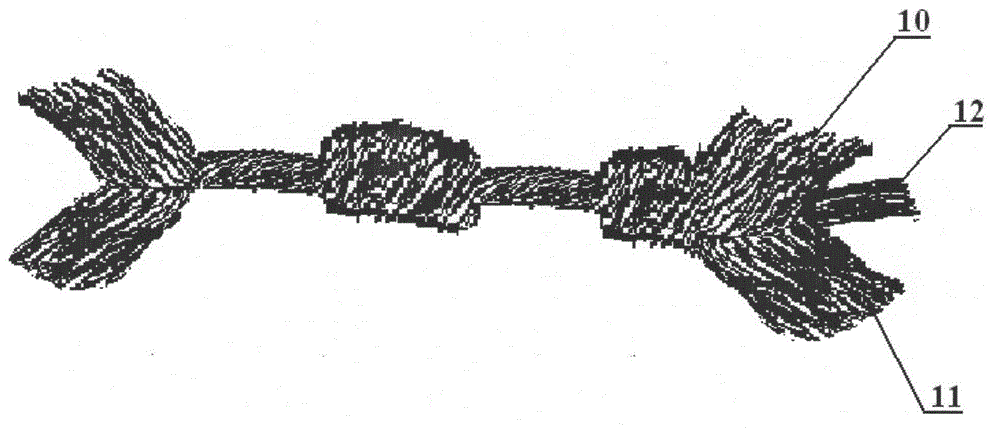

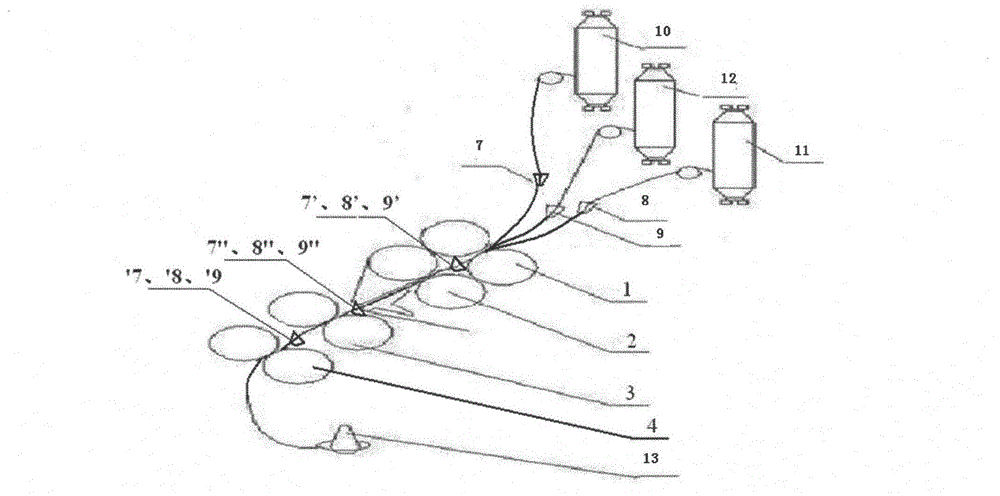

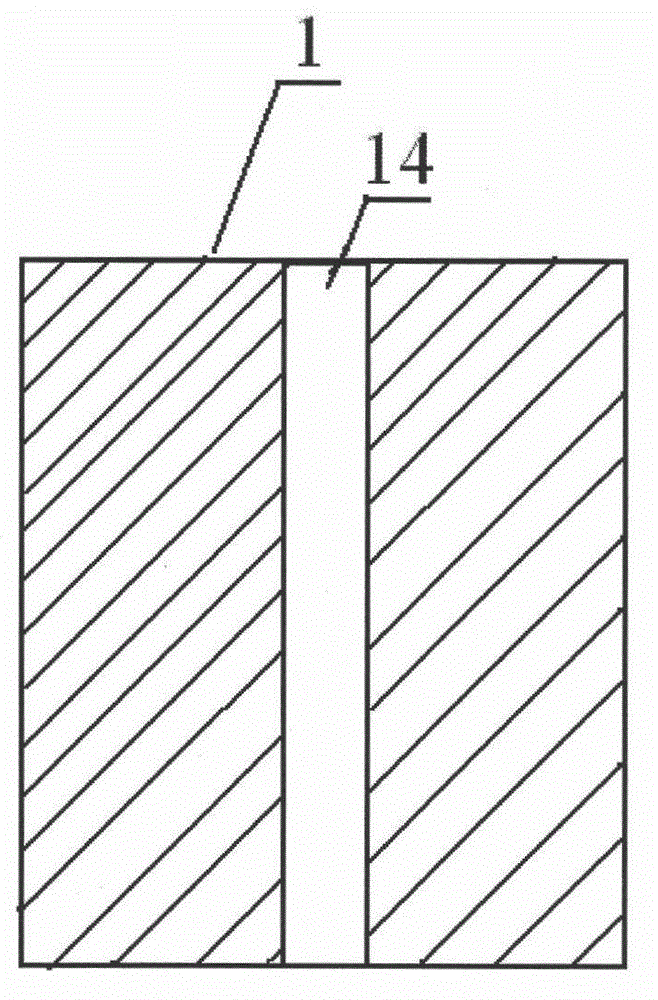

[0026] combine Figure 1 to Figure 6 , 2 parallel fiber bundles, i.e. parallel fiber bundle one 10 and parallel fiber bundle two 11, selected as cotton roving, the specification is 333tex; slub fiber bundle 12 selects bamboo fiber filament, the specification is 75 denier. Parallel fiber bundle 10 and parallel fiber bundle 2 11 are respectively fed into both sides of groove 1 14 of rear roller 1 through bell mouth 1 7 and bell mouth 2 8 respectively, and then respectively pass through bell mouth 3 7' and bell mouth 4 8' parallel to enter the two sides of the groove 2 15 of the middle roller 2, and after being stretched, pass through the bell mouth 5 7" and the bell mouth 6 8" respectively and enter the groove 3 5 and the groove 4 6 of the middle roller 3 in parallel , and then reach the front roller 4 in parallel through the bell mouth seven'7 and the bell mouth eight'8 respectively;

[0027] Pre-treatment of slub fiber bundle 12 impregnation, put the slub fiber bundle spindle...

Embodiment 2

[0029] combine Figure 1 to Figure 6 , 2 parallel fiber bundles, that is, parallel fiber bundle one 10 and parallel fiber bundle two 11, choose cotton roving and wool roving respectively, the specifications are 500tex and 333tex respectively; bamboo fiber bundle 12 choose bamboo fiber filament, the specification is 150 denier . Parallel fiber bundle 10 and parallel fiber bundle 2 11 are respectively fed into both sides of groove 1 14 of rear roller 1 through bell mouth 1 7 and bell mouth 2 8 respectively, and then respectively pass through bell mouth 3 7' and bell mouth 4 8' parallel to enter the two sides of the groove 2 15 of the middle roller 2, and after being stretched, pass through the bell mouth 5 7" and the bell mouth 6 8" respectively and enter the groove 3 5 and the groove 4 6 of the middle roller 3 in parallel , and then reach the front roller 4 in parallel through the bell mouth seven'7 and the bell mouth eight'8 respectively;

[0030] Pre-treatment of slub fiber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com