Washing method and washing machine applying same

A washing machine and flipping motor technology, applied to other washing machines, washing machine control devices, applications, etc., can solve the problems of poor spin-drying function, low washing degree, and clothes entanglement, so as to improve washing efficiency, low entanglement, The effect of less resistance to movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Embodiment 1, described laundry method mainly comprises the following operation steps:

[0061] The clothes are put into the inner cylinder 4, and the washing water is injected into the water holding cylinder 5 and the inside of the inner cylinder 4;

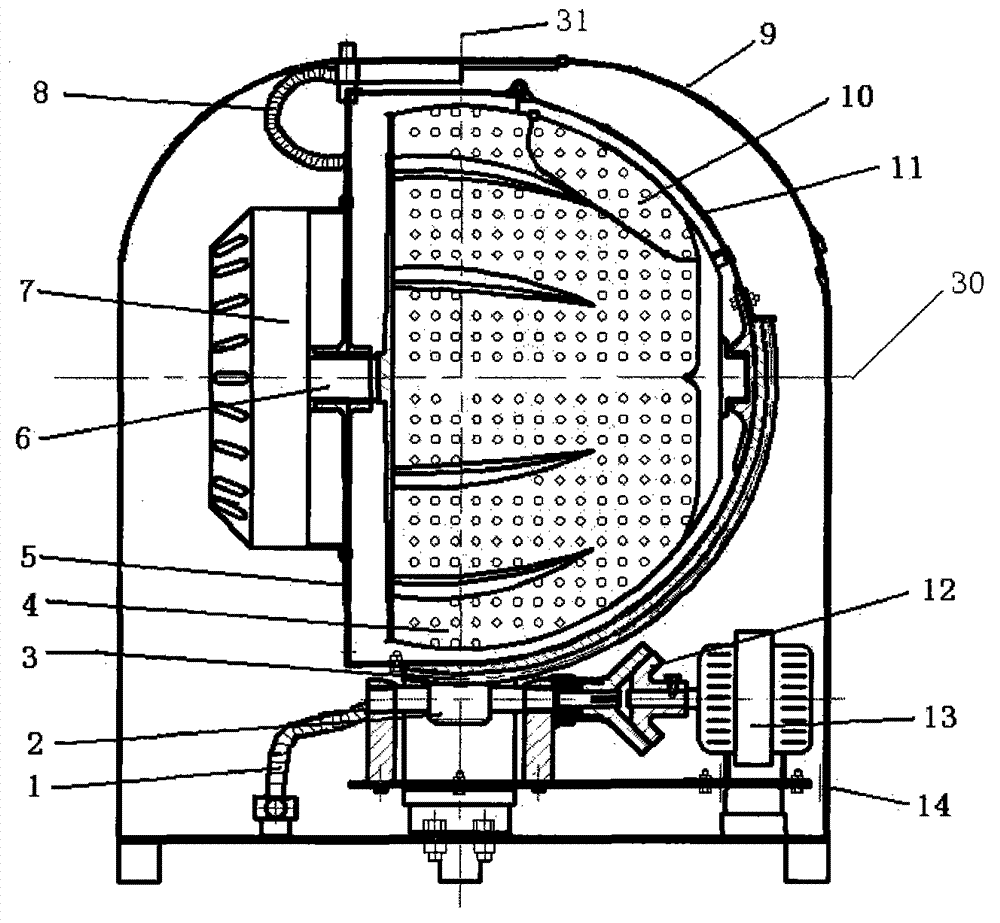

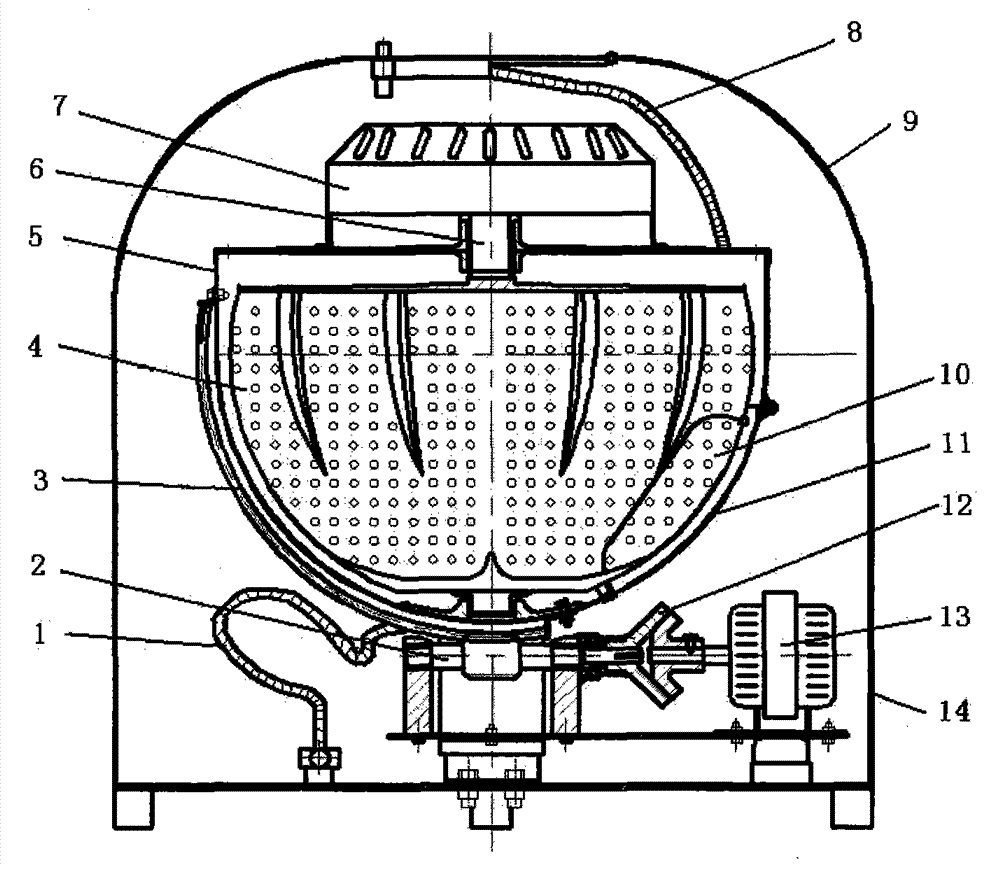

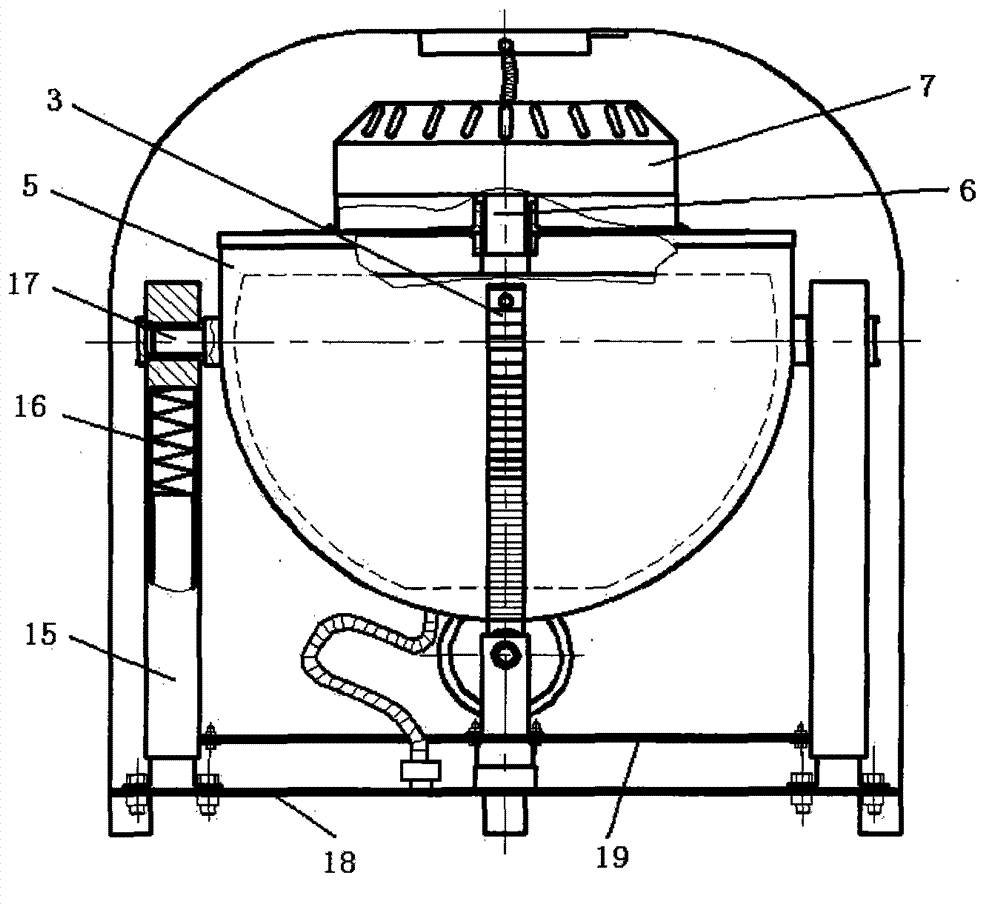

[0062] In the washing stage, the inner drum 4 rotates around the horizontal axis 30 driven by the driving motor 7, and the clothes are tumbled and washed in the inner drum 4 with the water flow;

[0063] In the rinsing stage, after the inner cylinder 4 is overturned by 90°, it rotates around the vertical axis 31 under the drive of the drive motor 7, and washing water is injected and discharged into the inner cylinder 4, and the rotational speed of the inner cylinder 4 in the rinsing stage is greater than that in the washing stage;

[0064] In the dehydration stage, the inner cylinder 4 rotates around the vertical axis 31 driven by the drive motor 7, and the washing water is discharged from the inner cylinder 4; the rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com