Load box for testing open caisson with self-balancing method

A self-balancing, load box technology, applied in the testing of infrastructure, construction, infrastructure engineering, etc., can solve the problems of limited tonnage and site conditions, high cost, long time, etc., to achieve large internal space, shorten construction period, assembly handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further specifically described below in conjunction with the embodiments and the accompanying drawings.

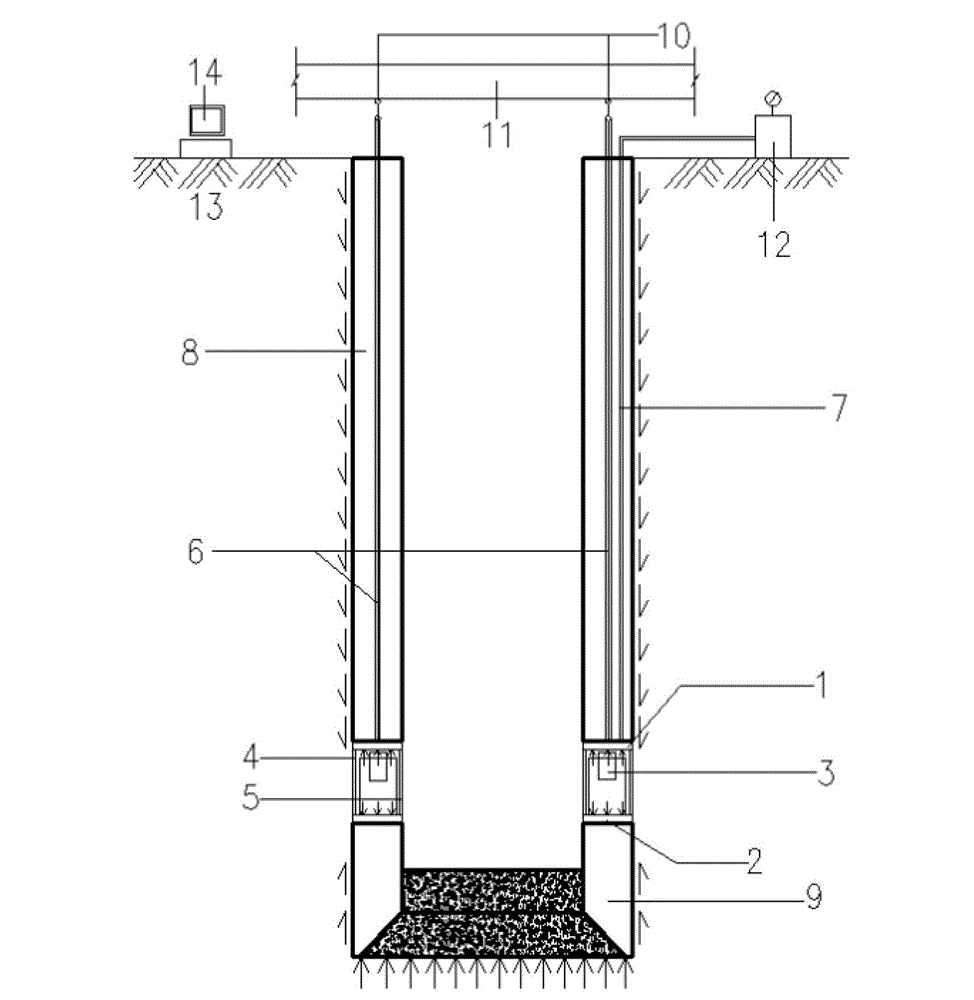

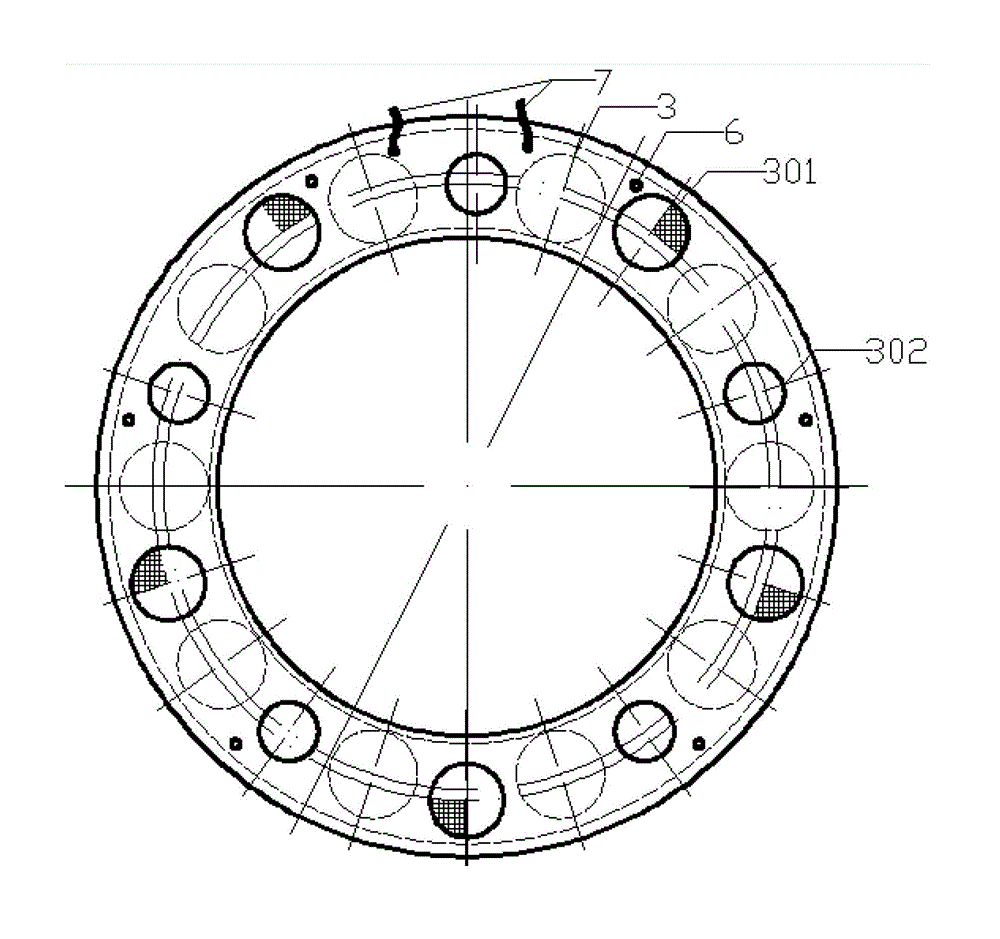

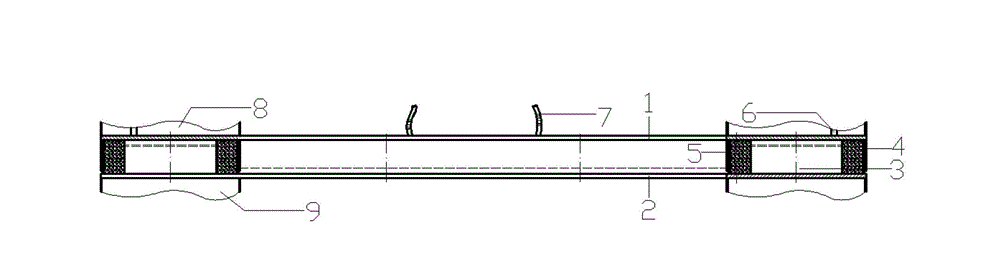

[0025] The load box used for caisson self-balancing method test of the present invention comprises an upper annular steel plate 1 and a lower annular steel plate 2 which are arranged up and down oppositely, a hydraulic oil cylinder 3 arranged between the upper annular steel plate 1 and the lower annular steel plate 2, an outer annular The baffle plate 4 and the inner annular baffle plate 5, the number of hydraulic cylinders 3 is ten, and the ring centers of the upper annular steel plate 1 and the lower annular steel plate 2 are symmetrically distributed, and the bottom of the cylinder body of the hydraulic cylinder 3 is connected by bolts. The upper surface of the steel plate 2, the piston of the hydraulic cylinder 3 is connected to the bottom surface of the upper annular steel plate 1, the outer annular baffle plate 4 is located at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com