Connecting structure of special aluminum profiles

A connection structure, special-shaped aluminum technology, applied in the connection of rods, connection components, upper structure, etc., can solve the problems of great hidden dangers in strength, strength influence, and influence on the appearance of the whole vehicle, so as to solve structural deformation and insufficient strength , to ensure firmness and reliability, and to improve the quality of the vehicle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

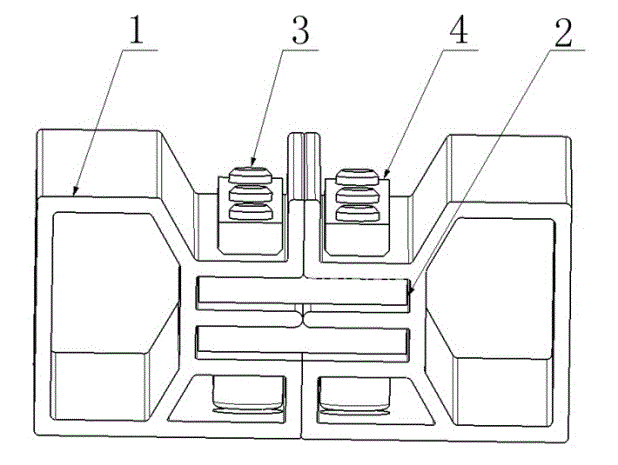

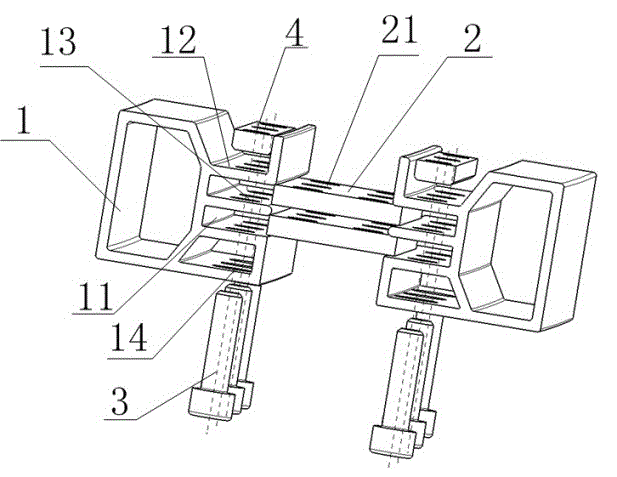

[0018] A connection structure of special-shaped aluminum profiles in this embodiment, such as figure 1 and figure 2 As shown, it includes two special-shaped aluminum profiles 1 connected in parallel. The special-shaped aluminum profile 1 includes a groove structure composed of two U-shaped grooves 11 arranged side by side. An outer groove 12 is respectively provided on both sides of the groove structure. The groove walls on both sides of the groove structure are respectively the groove bottom of the outer groove 12, and a plurality of screw holes 13 are opened on the groove wall of the groove structure, and the outer groove 12 of one of them is a closed structure, and is connected with the special-shaped aluminum profile 1 One outer surface forms a complete plane, and bolt through holes 14 corresponding to the screw holes 13 are opened on the plane. Reinforced aluminum plates 2 are respectively inserted in the mutually parallel U-shaped grooves 11 between the two special-sha...

Embodiment 2

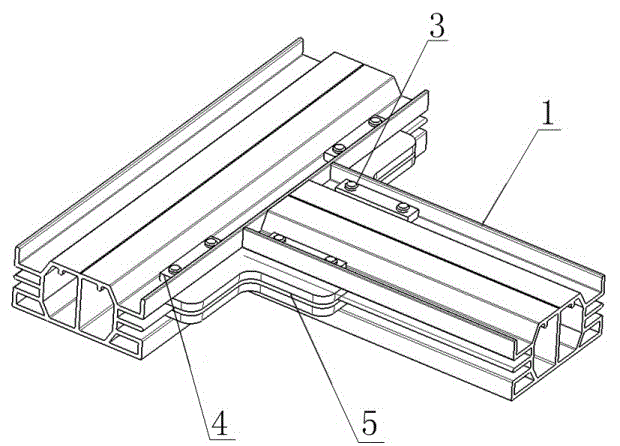

[0022] A connection structure of special-shaped aluminum profiles in this embodiment, such as image 3 and Figure 4 As shown, it includes two vertically connected special-shaped aluminum profiles 1. The special-shaped aluminum profile 1 includes a groove structure composed of two U-shaped grooves 11 arranged side by side. The two sides of the groove structure are respectively provided with outer grooves 12. The grooves The groove walls on both sides of the structure are respectively the groove bottom of the outer groove 12, and a plurality of screw holes (not shown in the figure) are opened on the groove wall of the groove structure, and the outer groove 12 of one of them is a closed structure, and is connected with An outer surface of the special-shaped aluminum profile 1 forms a complete plane, and a bolt through hole 14 corresponding to the screw hole is opened on the plane. Connecting aluminum plates 5 with right angles are respectively inserted in the mutually perpendic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com