Vehicle body aluminum profile structure

A technology for aluminum profiles and car bodies, which is applied to slender components, building components, etc., can solve the problems of affecting safety, hidden dangers of aluminum welding and welding strength, and low reliability of the car body, so as to achieve simple process, ensure connection strength and manufacturing accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

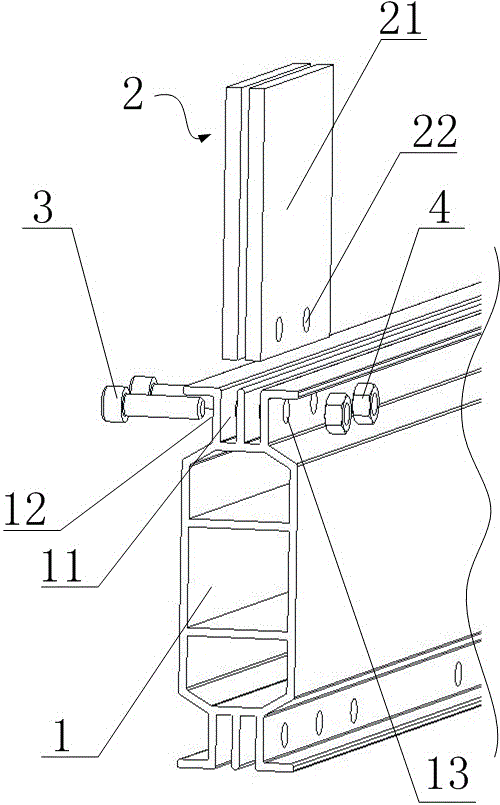

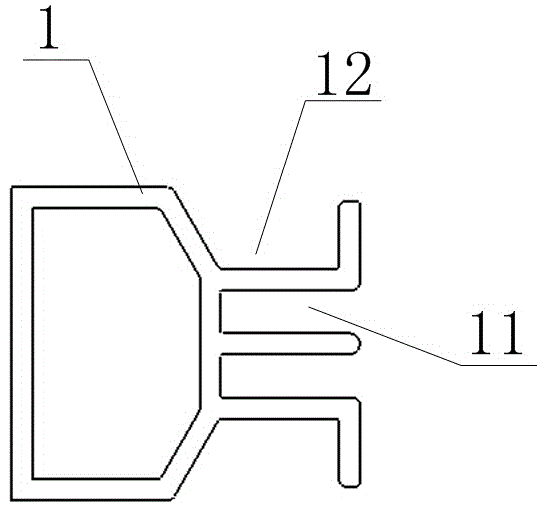

[0022] A kind of body aluminum profile structure of this embodiment, such as figure 1 and figure 2 As shown, an outer surface of the aluminum profile 1 is provided with a groove composed of two U-shaped grooves 11 arranged side by side. The two sides of the U-shaped grooves 11 arranged side by side are respectively provided with outer grooves 12. The groove walls are respectively the groove bottom of the outer groove 12, and the aluminum profile 1 is a plane in the opening direction of the U-shaped groove 11. A screw hole 13 is provided on the groove wall of the U-shaped groove 11 . It also includes the plate 2 to be installed for connecting and fixing with the aluminum profile, the plate 2 to be installed is an aluminum profile, steel plate or aluminum plate, and the plate 2 to be installed is provided with a plug whose shape and quantity are all matched with the U-shaped groove 11. Sheet 21, inserting sheet 21 is provided with holes 22, inserting sheet 21 is inserted into...

Embodiment 2

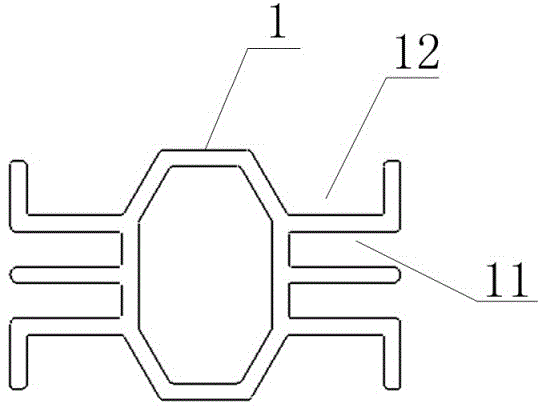

[0025] A body aluminum profile structure of this embodiment is basically the same as that of Embodiment 1, the difference lies in: as image 3 and Figure 4 As shown, two U-shaped grooves 11 and outer grooves 12 arranged side by side are respectively arranged on different outer surfaces of the aluminum profile 1, so that the connection between a single aluminum profile 1 and multiple plates to be installed can be realized, and the aluminum profile 1 can be Single hole, also can be multi-hole.

Embodiment 3

[0027] A body aluminum profile structure of this embodiment is basically the same as that of Embodiment 1, the difference lies in: as Figure 5 and Figure 6 As shown, two U-shaped grooves 11 and outer grooves 12 arranged side by side are arranged on one or more outer surfaces of the aluminum profile 1, wherein at least one of the outer grooves 12 is a closed structure, and is connected with the aluminum profile 1. One outer surface forms a complete plane, which is convenient for installing other components and decorations such as other aluminum profiles, steel plates or aluminum plates on the aluminum profile 1, wherein the aluminum profile 1 can be single hole or porous.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com