Energy-saving fully-automatic normally-lifting vacuum device

A vacuum device, fully automatic technology, applied in the pipeline system, mechanical equipment, gas/liquid distribution and storage, etc., can solve the problems of waste of working medium of tap water vacuum pumps, conflicting energy saving and emission reduction policies, etc., and achieve humanized management and improved Production safety and workload reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

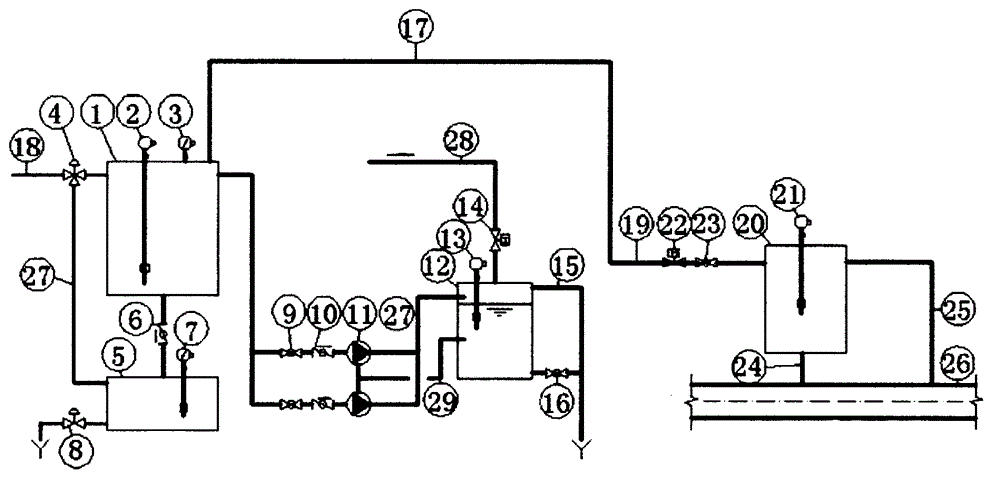

[0012] refer to figure 1 , this specific embodiment adopts the following technical scheme: it includes a vacuum tank 1, a liquid level switch 2, a pressure transmitter 3, an electric three-way valve 4, a drainage tank 5, a check valve 6, a liquid level switch 7, an electric valve 8 , manual valve 9, check valve 10, water ring vacuum pump 11, circulating water tank 12, liquid level switch 13, solenoid valve 14, overflow pipe 15, electric valve 16, vacuum main pipe 17, vent pipe 18, vacuum branch pipe 19, Constantly hanging vacuum unit 20, liquid level switch 21, solenoid valve 22, manual valve 23, water diversion pipe 24, suction pipe 25, water pipe to be diverted 26, vacuum pump water outlet pipe 27, tap water pipe 28 and vacuum pump water suction pipe 29, the described A liquid level switch 2 is arranged above the vacuum tank 1, a pressure transmitter 3 is arranged on one side of the liquid level switch 2, one side of the vacuum tank 1 is connected with the drainage tank 5 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com