Micro-flow detection method based on recognition of droplet images at pipeline outlet

A technology of image recognition and detection methods, applied in liquid/fluid solid measurement, measurement flow/mass flow, measurement devices, etc., to achieve low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

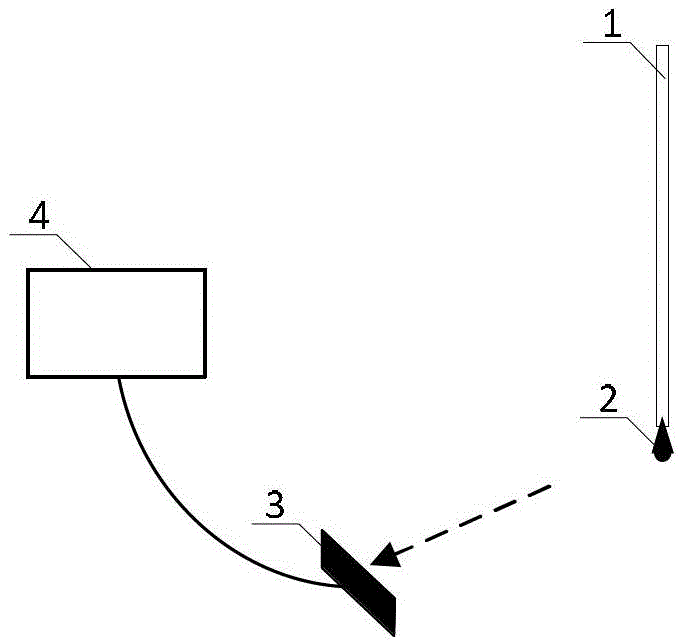

[0031] Embodiment 1 is a single-pipeline micro-flow detection device, such as figure 1 As shown, the detection device is composed of a camera or a camera 3 , a computer or an electronic computing device 4 .

[0032] In the pipeline outlet section 1, the liquid flows from top to bottom and forms a droplet 2 at the outlet of the pipeline. The droplet 2 gradually becomes larger and drops under the action of gravity, and then forms a new droplet 2 at the outlet of the pipeline; the camera Or the camera 3 is fixed on one side of the pipeline outlet section 1 to collect image information of the droplet 2 at the pipeline outlet in real time.

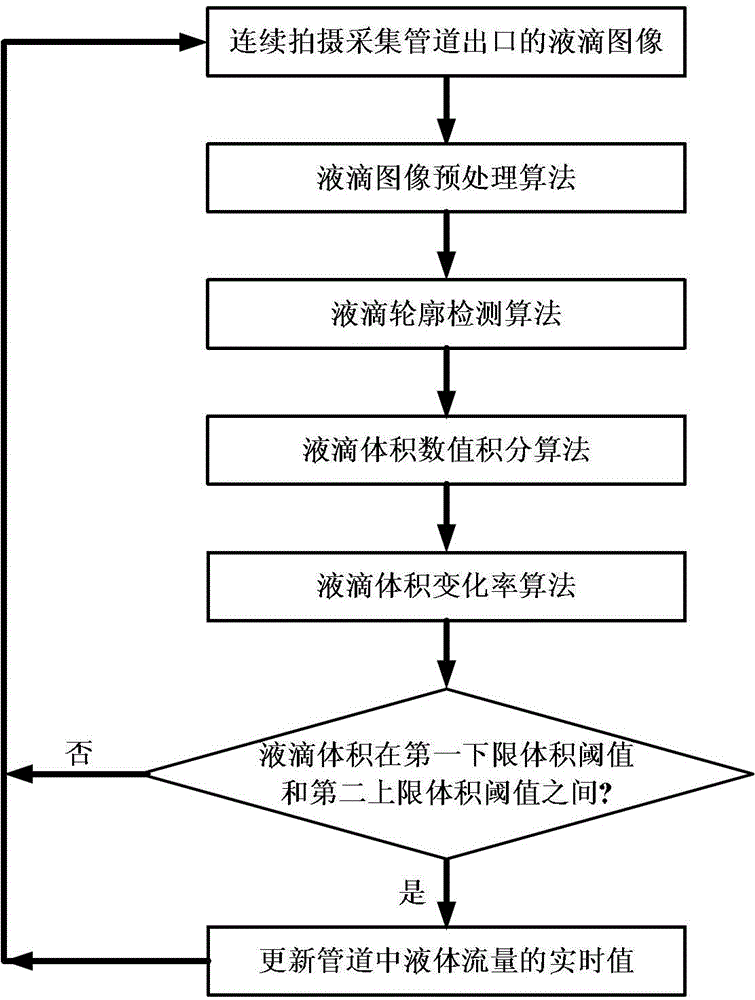

[0033] The camera or camera 3 continuously shoots and collects images of the pipeline outlet droplet 2 located at the end of the pipeline outlet section 1, and the computer or electronic computing device 4 calculates the volume change of the droplet according to the droplet image to calculate the liquid flow in the pipeline in real time.

[00...

Embodiment 2

[0088] Embodiment 2 is a multi-pipeline micro-flow detection device, such as Figure 7 As shown, the detection device is composed of a camera or a camera 3 , a computer or an electronic computing device 4 . Wherein the pipeline outlet section 1 is a pipeline outlet section array composed of a plurality of pipeline outlet sections.

[0089] Since the collected image is a droplet array, the image needs to be segmented first to obtain an image of a single droplet, and then the calculation is performed for each droplet according to the microflow detection algorithm flow in Embodiment 1.

[0090] The purpose of this embodiment is to simultaneously perform real-time, on-line, accurate, low-cost, and non-contact flow detection of liquids in multiple micro-pipes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com