Measurement method of coating rate of paper-making reconstituted tobacco

A technology for reconstituting tobacco leaves and measuring methods, which can be applied in the direction of removing certain components and weighing, etc., can solve the problems of not fully meeting the needs of use, time-consuming operation, etc., and achieve the effect of reliable technical parameters and test data.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A method for measuring the spread rate of reconstituted tobacco leaves by a papermaking method, the specific steps are as follows:

[0022] (1) Dry the finished paper-making reconstituted tobacco leaves and the sample boxes in an oven at 90±1°C for 2 hours, then cool them in the desiccator for 30 minutes, and weigh the sample boxes respectively in m 0 =96.192g, papermaking reconstituted tobacco leaves m 1 =2.083g. The finished paper-making reconstituted tobacco leaves and sample boxes were dried in an oven at 90±1°C for 2 hours, and then cooled in a dryer for 30 minutes.

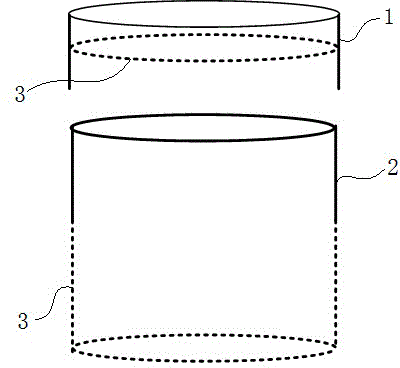

[0023] (2) Put paper-making reconstituted tobacco leaves in a sample box, cover them, soak them in water with a material-to-liquid ratio of 1g:500mL for 180s, take them out and dry them; then dry them in an oven at 90±1°C for 2 hours and then dry them. Cool in the container for 30 minutes, weigh m 2 =97.598g.

[0024] (3) Calculate the coating rate x of reconstituted tobacco leaves by papermaking ...

Embodiment 2

[0026] A method for measuring the spread rate of reconstituted tobacco leaves by a papermaking method, the specific steps are as follows:

[0027] (1) Dry the finished paper-making reconstituted tobacco leaves and 6 sample boxes in an oven at 90±1°C for 2 hours, then cool them in the desiccator for 30 minutes, and weigh the sample boxes respectively in m 0 .

[0028] (2) Weigh 6 parts of different weights of paper-making reconstituted tobacco leaves m 1 Put it in the sample box and cover it, soak each sample in water with two solid-liquid ratios of 1g:500mL at room temperature for 180s, take it out and dry it; then dry it in an oven at 90±1°C for 2 hours, then cool it in a desiccator for 30 minutes and weigh it m 2 . Measured m 0 、m 1 、m 2 The data are shown in Table 1.

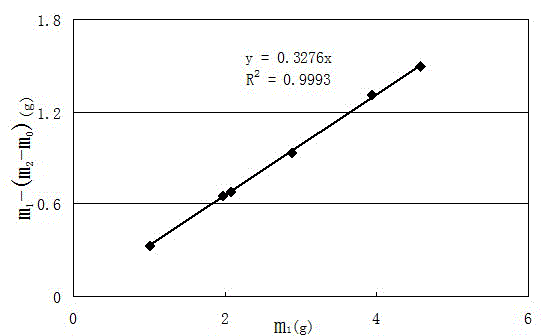

[0029] (3) in m 1 is the abscissa, m 1 -(m 2 -m 0 ) is the ordinate, and the slope obtained by straight line fitting is the coating rate x=32.76%. Such as figure 1 shown.

[0030] table 1 m 0 、...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com