Gallium nitride base light-emitting diode with composite potential barrier

A technology of light-emitting diodes and composite potential barriers, applied in electrical components, circuits, semiconductor devices, etc., can solve problems such as lattice mismatch, achieve uniform distribution, improve composite efficiency, and improve performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Assuming the following GaN-based LED In u Ga 1-u The In composition in the N well layer 51 is u=0.2.

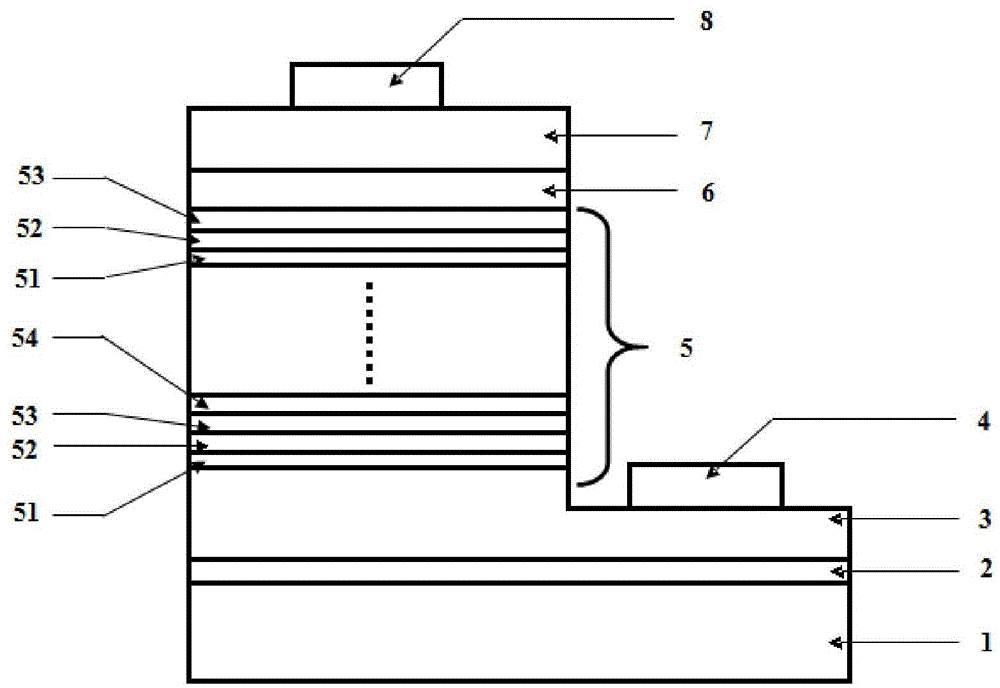

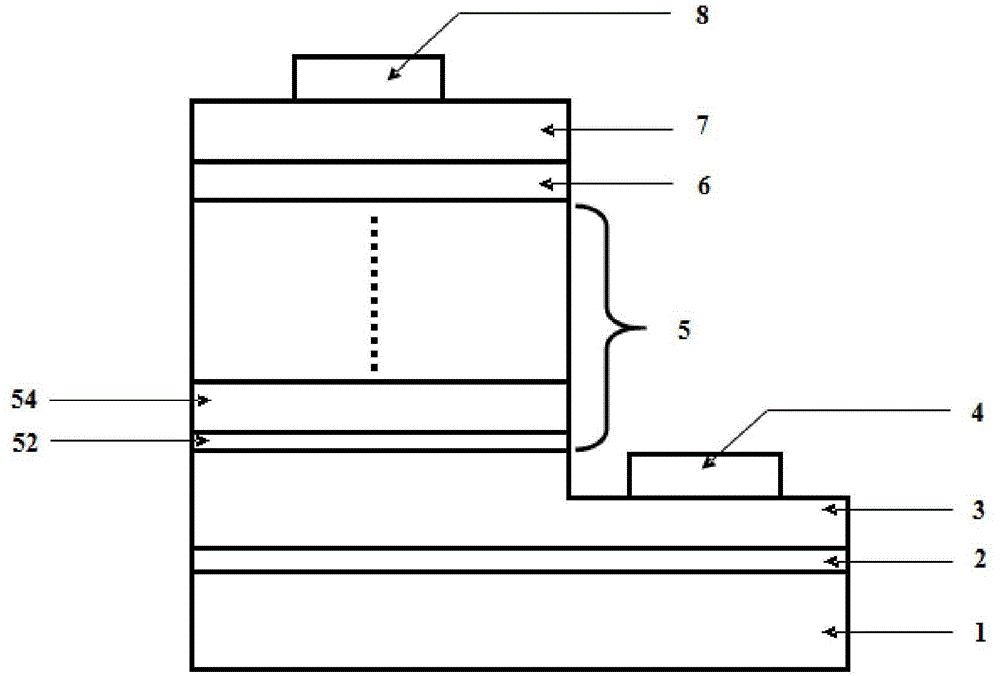

[0059] figure 1 What is shown is the structural schematic diagram of the GaN-based LED with composite potential barrier according to the present invention. The structural elements of this LED include: sapphire substrate 1, buffer layer 2, n-type gallium nitride epitaxial layer 3, n-type electrode 4, multi-quantum well active region 5, indium gallium nitride potential well layer 51, the first AlGaInN layer 52 , GaN layer 53 , second AlGaInN layer 54 , p-type AlGaN epitaxial layer 6 , p-type GaN epitaxial layer 7 , and p-type electrode 8 .

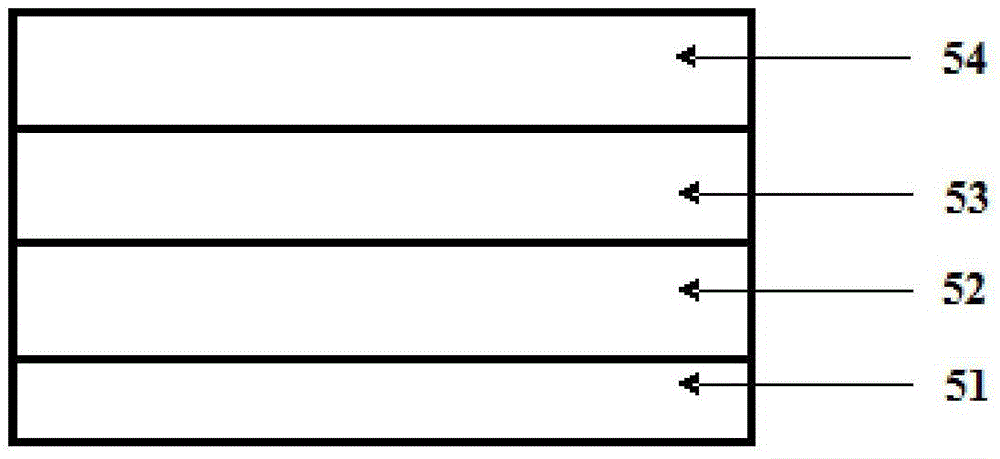

[0060] image 3 Shown is a schematic diagram of a single quantum well with a first-type composite barrier layer of AlInGaN-GaN-AlInGaN, including In 0.2 Ga 0.8 NInGaN potential well layer 51, the first AlGaInN layer 52, the first AlGaInN layer 52 and In 0.2 Ga 0.8 At the interface where the NInGaN layer 51 contacts, according...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com