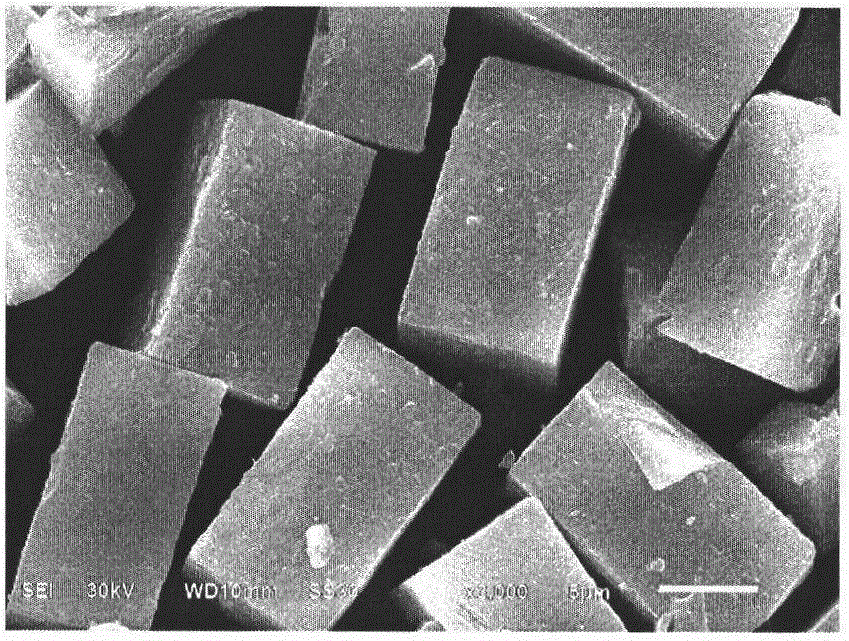

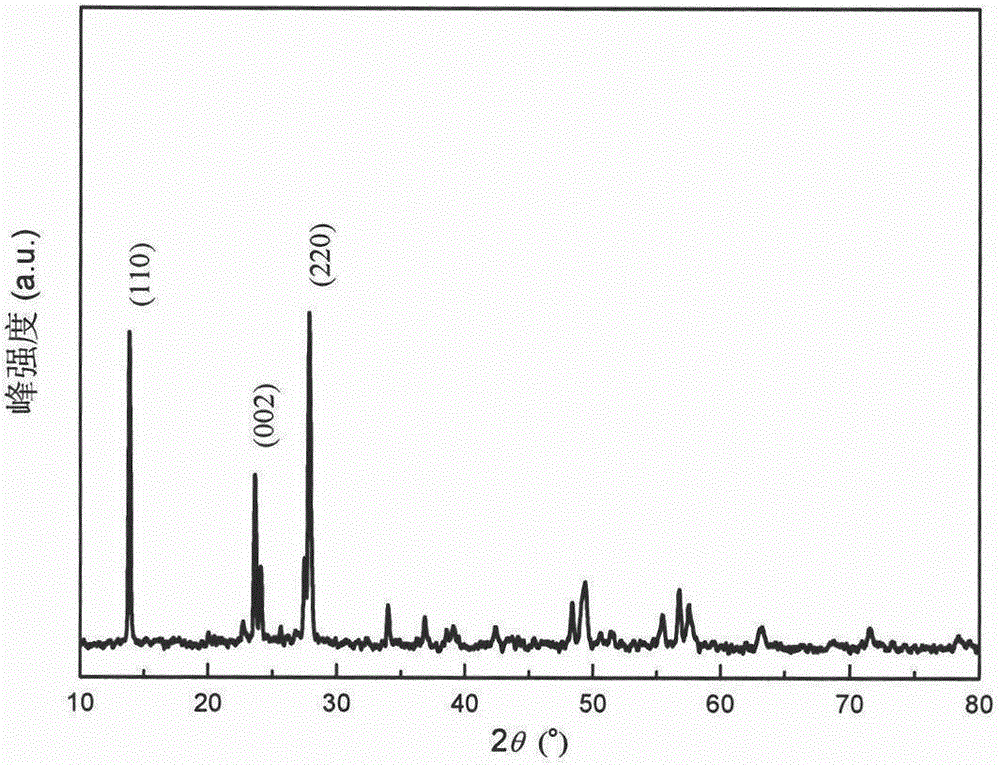

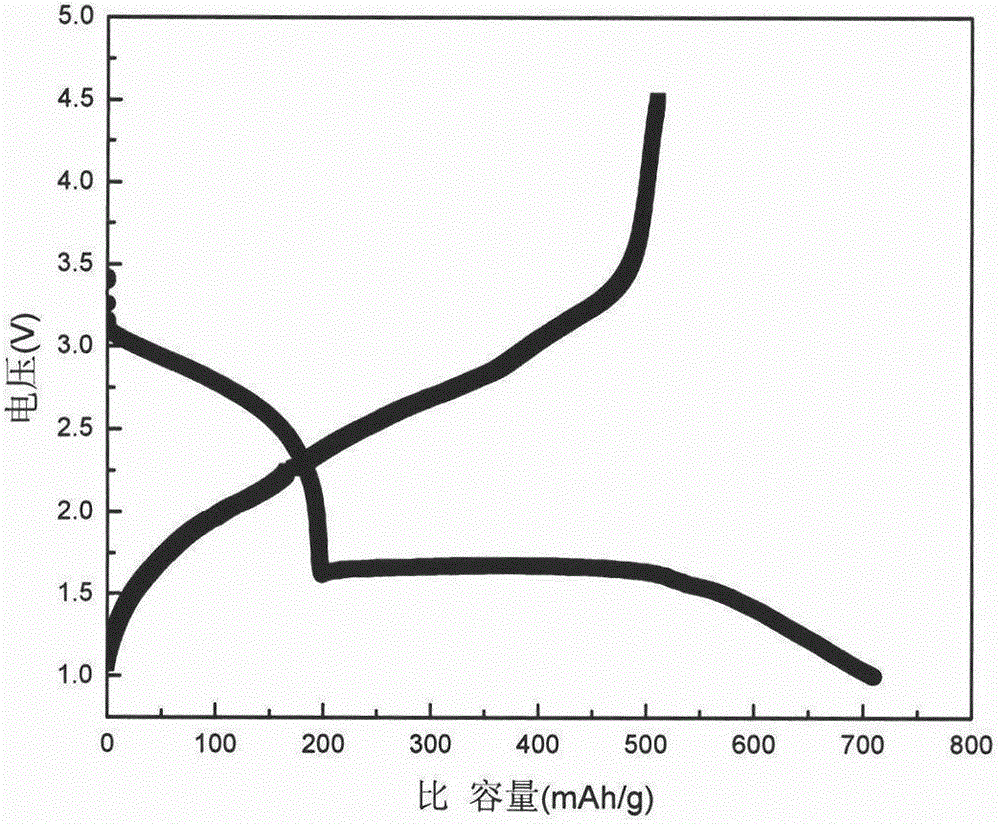

Preparation method of cuboid-shaped positive-pole FeF3(H2O)0.33 material

A cathode material, cuboid technology, applied in the field of preparation of cuboid-shaped FeF30.33 cathode material, can solve problems such as poor cycle performance, achieve high stability, environmental friendliness, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Weigh 4.0462g FeNO 3 9H 2 O, add 25mL absolute ethanol to make 0.4mol / L FeNO 3 solution, add 0.010g cetyltrimethylammonium bromide, put it into a polytetrafluoroethylene container, and slowly add 40wt.% HF at a molar ratio of 1:4 under constant stirring at 25°C, stir for 1h, and remove into the hydrothermal reactor. Then put it in a dry box, conduct a hydrothermal reaction at 80°C for 12 hours, and cool down to obtain a pink precipitate. Pour off the supernatant, add 20 mL of absolute ethanol, wash, filter with suction, and dry at 80° C. for 12 hours in an air atmosphere to obtain a pink product. Dry in a vacuum oven at 180°C for 12 hours to obtain FeF 3 (H 2 O) 0.33 Material.

Embodiment 2

[0030] Weigh 2.7030g FeCl 3 ·6H 2 O, add 25mL absolute ethanol to make 0.4mol / L FeCl 3 solution, add 0.010g cetyltrimethylammonium bromide, put it into a polytetrafluoroethylene container, and slowly add 40wt.% HF at a molar ratio of 1:4 under constant stirring at 25°C, stir for 1h, and remove into the hydrothermal reactor. Then put it in a dry box, conduct a hydrothermal reaction at 90°C for 10 hours, and cool down to obtain a pink precipitate. Pour off the supernatant, add 40mL of absolute ethanol, wash, filter with suction, and dry at 90°C for 6h in an air atmosphere to obtain a pink product. Dry in a vacuum oven at 200°C for 10 hours to obtain FeF 3 (H 2 O) 0.33 Material.

Embodiment 3

[0032] Weigh 4.0462g FeNO 3 9H 2 O, add 50mL absolute ethanol to make 0.2mol / L FeNO 3 solution, add 0.008g citric acid, put it into a polytetrafluoroethylene container, at 25°C with constant stirring, slowly add 20wt.% HF at a molar ratio of 1:4, stir for 0.5h, and move to a hydrothermal reaction kettle. Then put it in a dry box, conduct a hydrothermal reaction at 60°C for 24 hours, and cool down to obtain a pink precipitate. Pour off the supernatant, add 20 mL of absolute ethanol, wash, filter with suction, and dry at 60° C. for 12 hours in an air atmosphere to obtain a pink product. Dry in a vacuum oven at 170°C for 15 hours to obtain FeF 3 (H 2 O) 0.33 Material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com