Textile sleeve with protective coating and method for its construction

一种套筒、纺织的技术,应用在纺织品和造纸、管道保护、装饰用纺织品等方向,能够解决多层套筒成本高等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

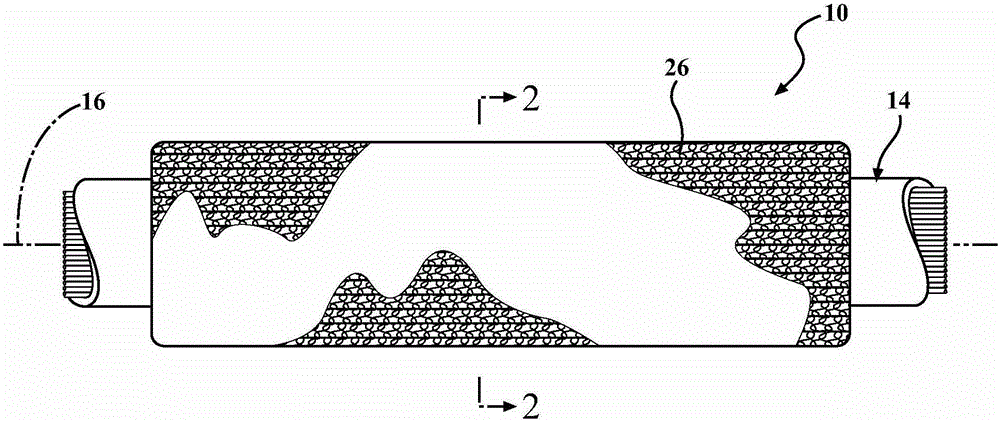

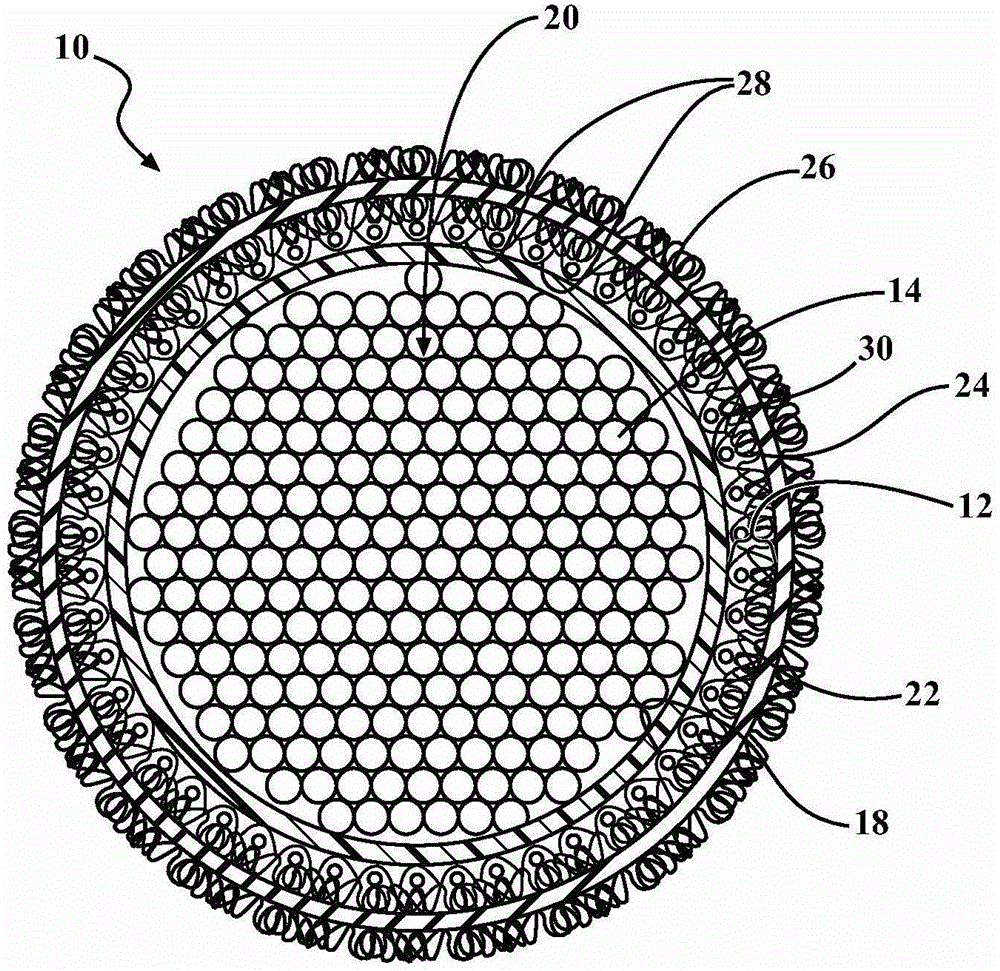

[0014] Referring more specifically to the accompanying drawings, figure 1 A schematic side view of a coated textile sleeve, hereinafter referred to as sleeve 10, constructed in accordance with one aspect of the present invention is shown. The sleeve 10 has an elongated textile inner wall 12 ( figure 2 ) for guiding and protecting the elongated member, such as an electrical wire or harness 14, from exposure to abrasion and other environmental conditions, such as exposure to fluids. The elongated wall 12 extends along a longitudinal central axis 16 and has an inner surface 18 and an outer surface defining an inner cavity 20, wherein the inner surface 18 is configured to provide soft damping to the elongated member 14 to be protected. non-abrasive surface. The textile wall 12 also has an outer surface 22, and a permeable impermeable elastomeric coating 24 bonded thereto to provide the wall 12 with fluid impermeability so as to protect the elongate member 14 from fluid contami...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com