Gear blank production technology method with hammer forging and die forging combined

A process method and technology of gear blanks, which are applied in the directions of wheels, transportation and packaging, vehicle parts, etc., can solve the problems of difficulty in guaranteeing mechanical properties, waste of metal materials, and large tolerances of gear blanks, etc. Material saving and small forging tolerances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

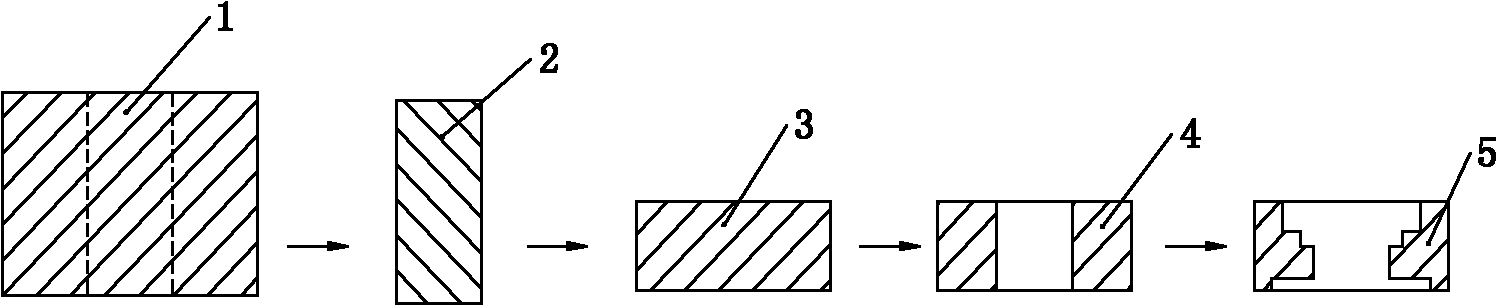

[0023] like figure 1 As shown, a kind of process method of adopting open die forging and die forging to produce gear blank according to the present invention, it comprises the following steps:

[0024] a) Making electroslag ingots: cast molten steel into steel ingots or continuous casting slabs for electroslag remelting to obtain electroslag ingots, and then anneal the electroslag ingots to eliminate stress; steel ingots or continuous casting slabs are being processed Before electroslag remelting, it is made of raw materials through smelting, LF refining, vacuum degassing, annealing and surface cleaning;

[0025] b) Prepare the blank before forging: Saw the head and tail of the electroslag ingot 1 and divide it by blanking to make the blank 2 before forging;

[0026] c) Heating of billet 2: heating the billet 2, the initial forging heating temperature is 1150°C to 1280°C;

[0027] d) First billet opening: free forging the heated billet 2 to make a round cake-shaped billet 3;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com