Machining Method of Slender Blind Hole on Cylinder Block of 100KW High Voltage Nuclear Power Steam Turbine

A steam turbine and nuclear power technology, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve problems such as difficult processing of slender blind holes and inability to guarantee processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

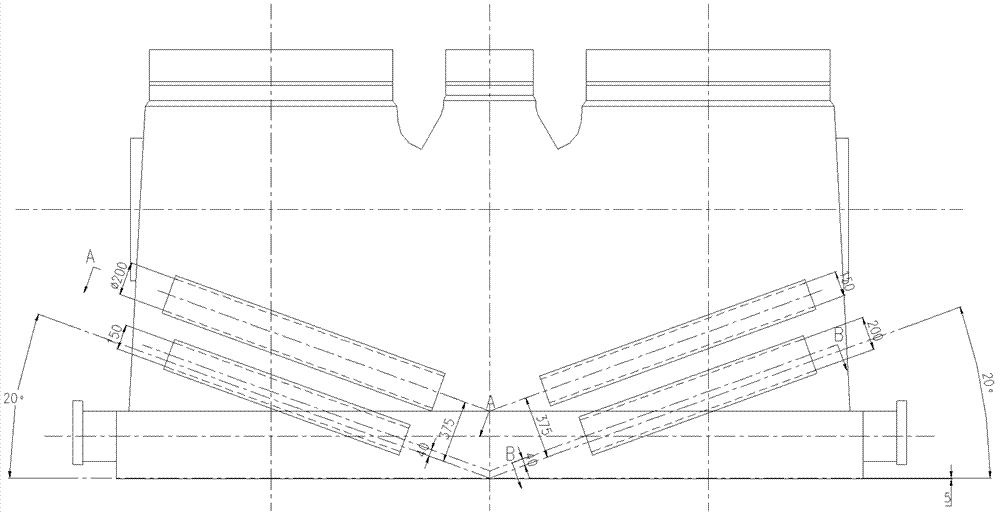

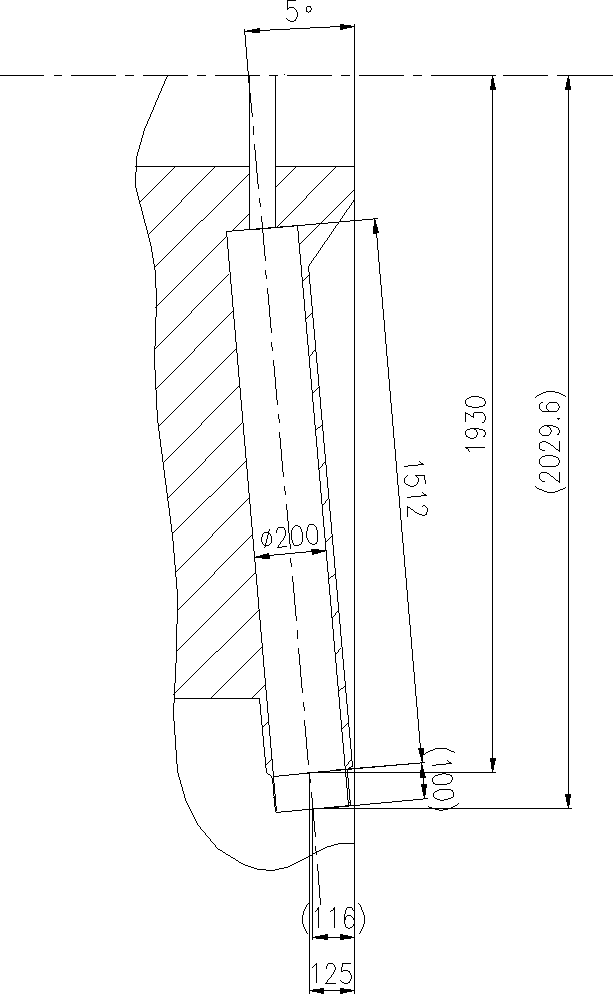

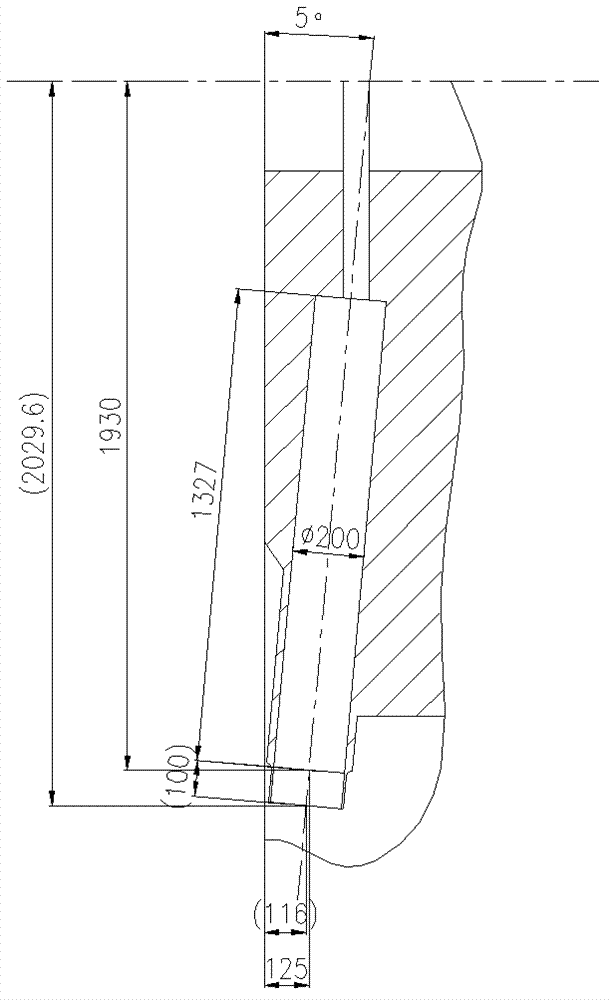

[0032] The processing method of the slender blind hole on the cylinder block of the 100 kilowatt high-voltage nuclear power steam turbine of the present invention adopts such as Figure 4 The positioning control tool shown in the figure can process a straight hole on the cylinder with an included angle of 20° to the horizontal plane and a 0° included angle to the vertical plane, and a straight hole with an included angle of 0° to the horizontal plane. 20° space angle hole with an included angle of 5° with the vertical plane at the same time;

[0033] The positioning control tooling includes a base 1, the base 1 has a slope 2, and a positioning block 3 is arranged at the bottom of the slope 2; a center hole 4 is arranged on the slope 2 at the center of gravity of the base 1 (the center hole 4 is the center of the positioning control tooling );

[0034] There is an angle of 20° between the slope 2 and the bottom surface of the base 1;

[0035] Processing method of the present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com