Multi-printing-head third-dimensional (3D) printer technology of rotary platform

A technology of 3D printers and rotating platforms, applied in the field of 3D printers, can solve problems affecting printing speed, etc., and achieve the effects of improving printing efficiency, ingenious ideas, and reasonable designs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

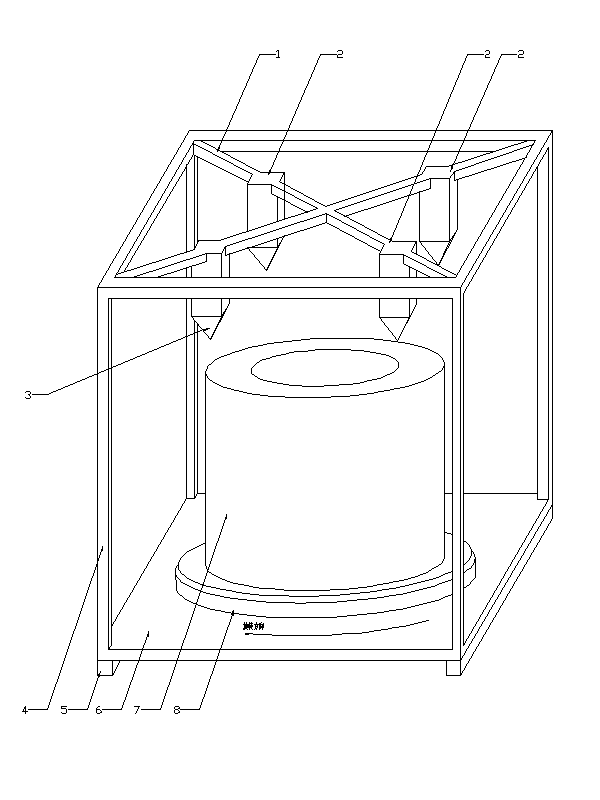

[0010] refer to figure 1 , a multi-print head 3D printer with a rotating platform, including multiple sets of top rails 1, print head travel mechanism 2, multiple print head extrusion mechanisms 3, related brackets 4, outriggers 5, chassis 6, printed parts 7, and rotation at a constant speed The platform consists of 8. The print head extruding mechanism 3 is installed on the printer traveling mechanism 2 and performs reciprocating motion on the top track. The bottom uniform rotating platform 8 rotates with the center of the platform as the central axis.

[0011] Each group of rails 1 on the top and the same group of print head traveling mechanism 2 and print head extruding mechanism 3 form a set of printing mechanisms that are linked. This set of printing mechanism has the same function as the conventional 3D printer extrusion head mechanism, and can reciprocate on its own top track 1 . The bottom rotating platform 8 rotates at a constant speed with the center point as the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com