Cab shell of high-speed rail vehicle and its processing method

A high-speed track and driver's cab technology, which is applied in the field of improvement of the cab shell structure, can solve problems such as the difficulty in meeting the driving requirements of high-speed vehicles and safety performance defects, and achieve the effects of high processing accuracy, high production efficiency, and protection of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

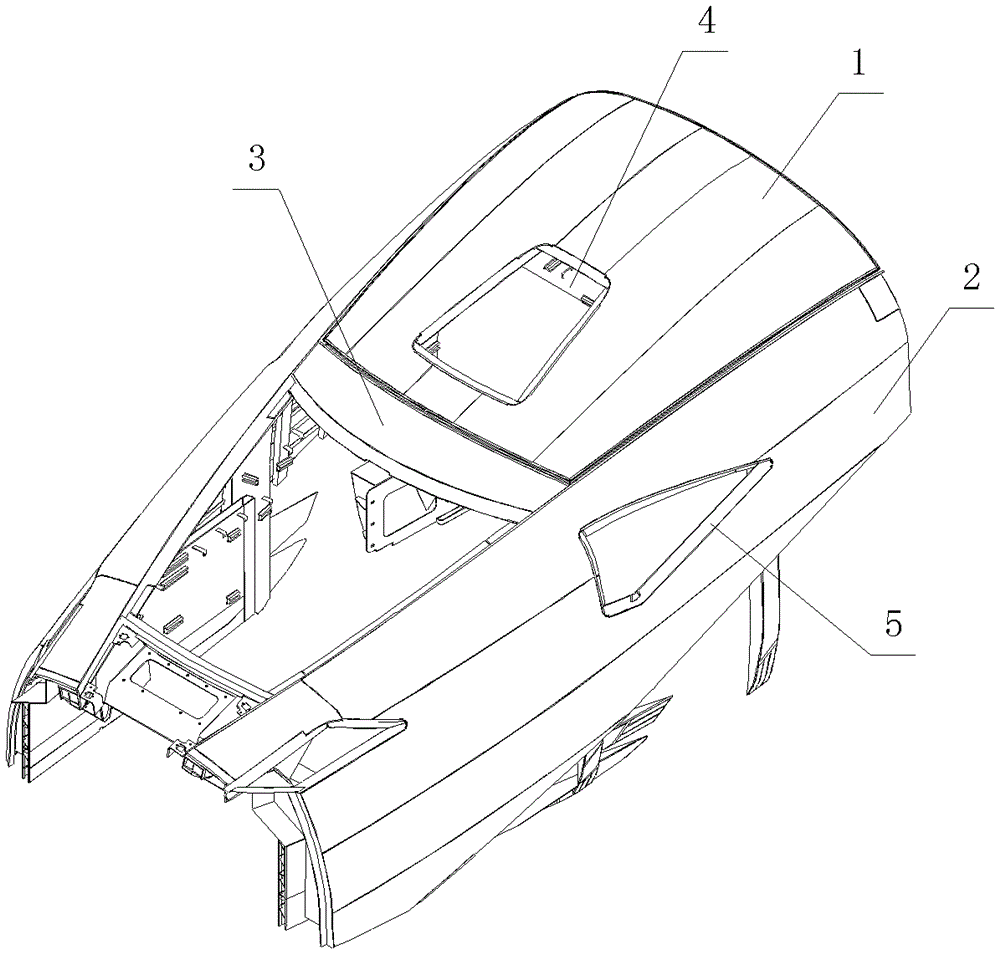

[0027] Example 1, such as figure 1 As shown, the described high-speed rail vehicle driver's cab shell mainly includes:

[0028] The skin and frame 3 welded to the car body;

[0029] The skin includes roof skin 1, side wall skin 2, roof module 4 and side wall module 5;

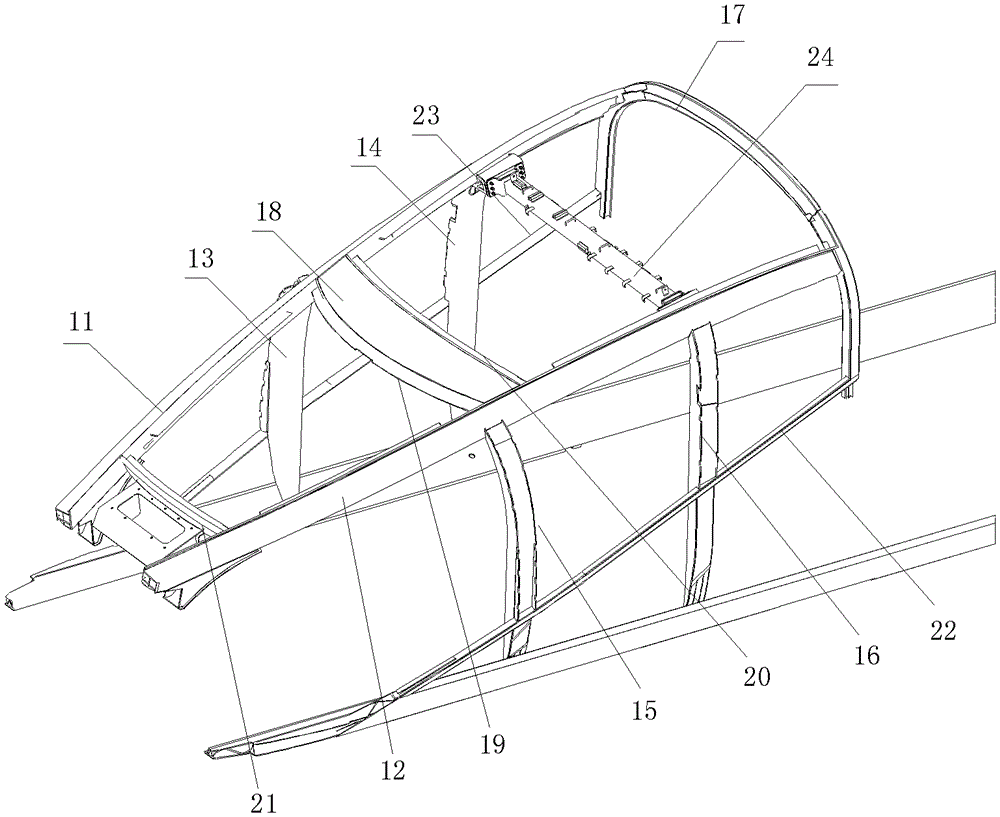

[0030] The skeleton 3 includes a first right column 11, a first left column 12, a right front column 13, a right rear column 14, a left front column 15, a left rear column 16, an end wall curved beam 17, and a front window beam 18 , the first front window beam flange 19, the second front window beam flange 20, the front end beam 21, the left side wall connecting curved beam 22, the right side wall connecting curved beam 23 and the roof riveting beam 24.

[0031] Wherein, the above-mentioned parts constituting the skin and the skeleton 3 are stretch-bent profiles formed by one-time processing;

[0032] The roof skin 1, the side wall skin 2, the side wall module 5 and the frame 3 are connected through full pen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com