Sheet metal automatic transferring equipment

A technology for sheet metal and transfer equipment, which is applied in the directions of sending objects, supplying objects, and separating piles, etc., can solve the problems of inability to use steel plates, low efficiency, plate damage, etc., and achieve the effect of compact device structure, convenient maintenance and reasonable layout.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in combination with specific embodiments.

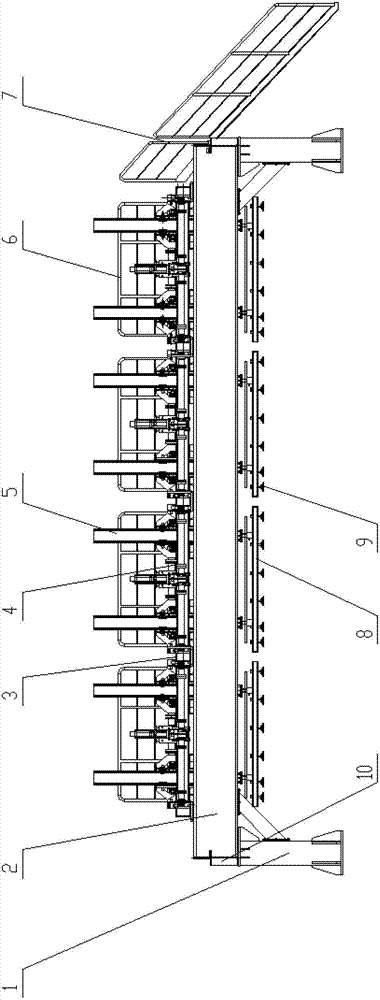

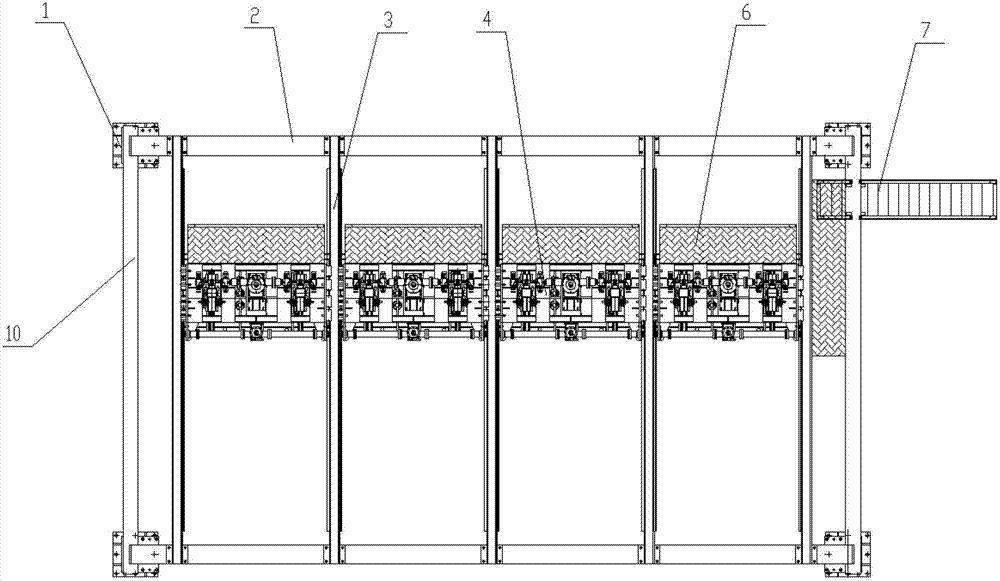

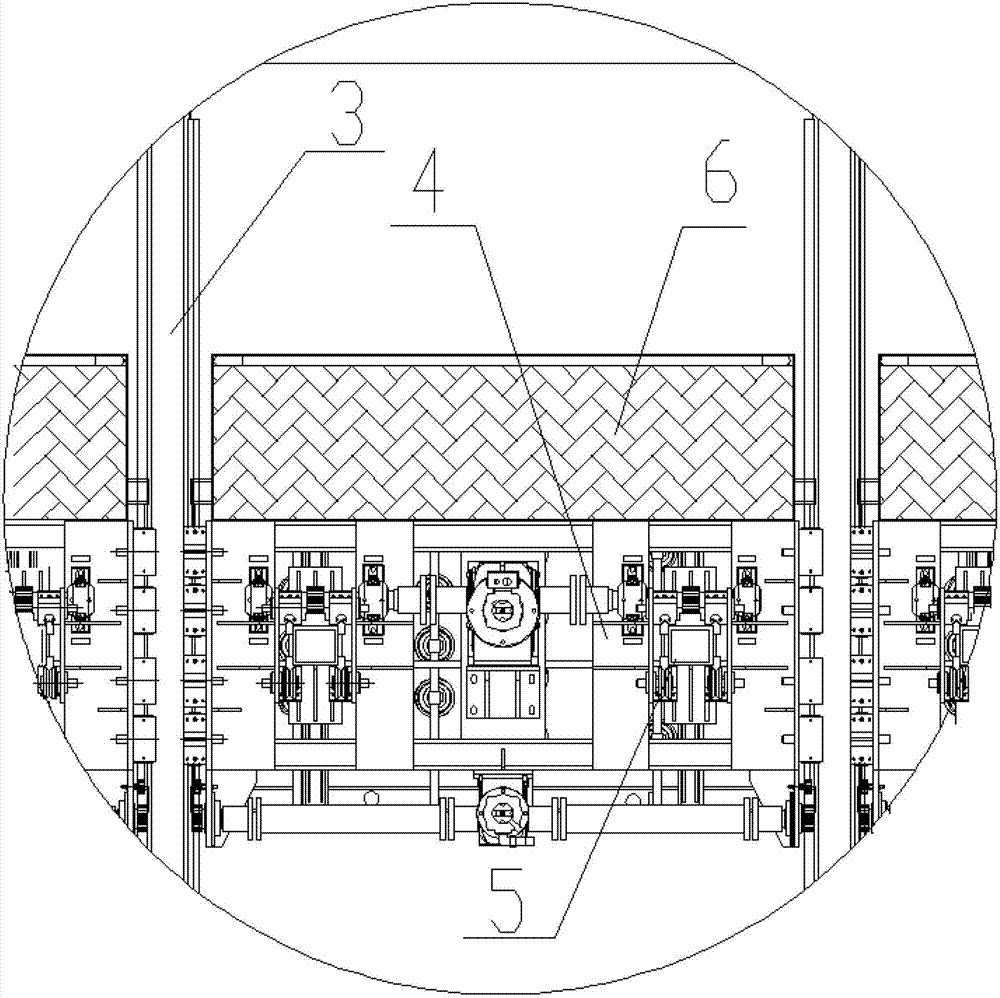

[0028] see Figure 1-Figure 4 , the present invention aims at the problems of high-temperature fast-paced production line sheet metal material loading, unloading, collection and stacking, transfer and the like. Provided is a plate high-speed high-temperature automatic suction cup transfer machine, mainly composed of a column 1, a load-bearing beam 2, a guide rail beam 3, a transfer device 4, a lifting device 5, an inspection platform 6, an inspection staircase 7, a suction cup hanger 8, and a high-temperature suction cup 9 , bearing sub-beam 10 etc., the present invention is compact in structure, and equipment is grouped, and interchangeability is strong.

[0029] The column 1 is fixed on the foundation, the load-bearing girder 2 is connected to the column, the load-bearing sub-beam 10 connects the column 1 and the load-bearing girder 2 on the outside, the guide rail beam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com