Method and equipment for brush plating conductive metal on railway rail surface

A conductive metal and rail technology, which is applied in the field of brush-plating conductive metal on the surface of railway rails, can solve problems such as unreliable use of track circuits, poor track circuit shunts, and signal system failure to display, etc., to solve poor track circuit shunts and reduce The effect of artificial labor intensity and reducing the impact of brush plating quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

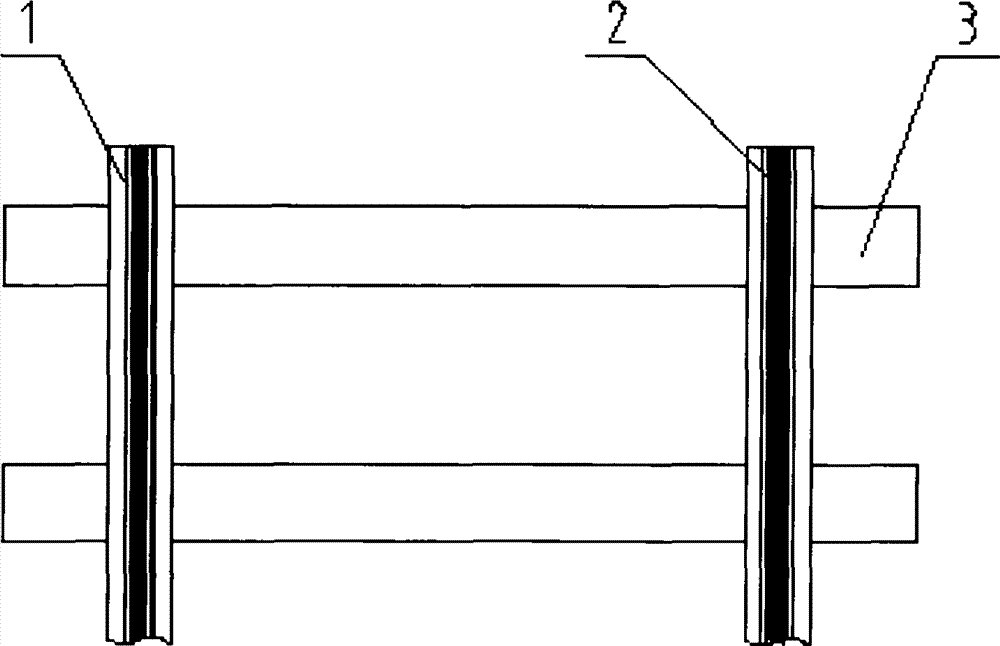

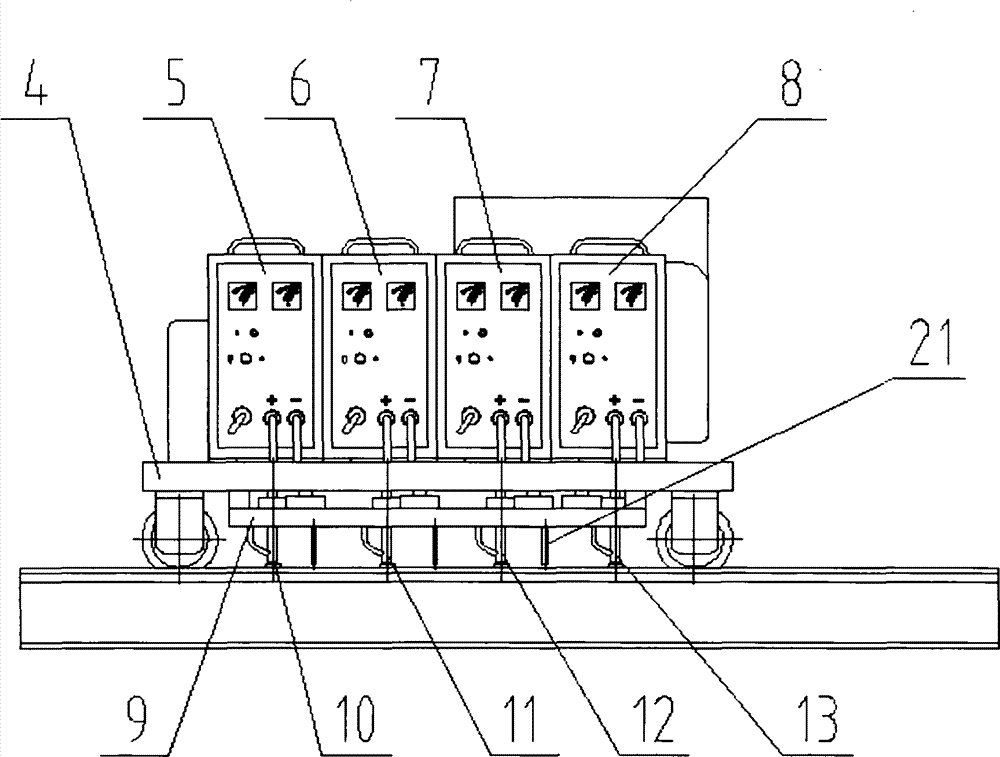

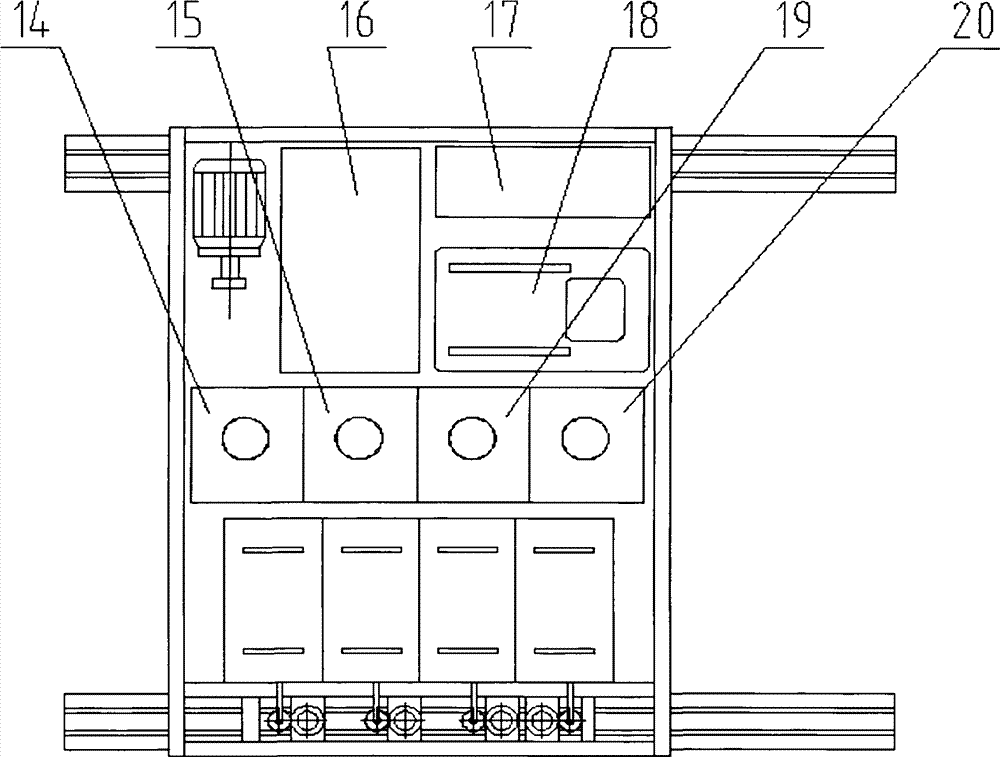

[0029] A method for brush-plating conductive metal on the surface of a railway rail. The method is to mechanically brush-plat a rust- and corrosion-resistant conductive metal on the surface 1 of the rail head to form a brush-plated conductive metal layer 2, and the rail is supported by sleepers 3. Including the rust removal step. The rust removal is to remove the rust on the surface of the rail head. The standard is to expose the true color of the rail. The rust can be manually or mechanically removed, and the hand-push rail can be suspended at the front of the car body. The rust machine or mechanical rail rust remover is completed. The method and equipment of the present invention are carried out simultaneously on one side of the rail. It also includes the following steps:

[0030] Electric cleaning: spraying and brushing electric cleaning fluid on the surface of the rail head after the rust removal step to clean the surface of the rail head. It is completed by the electric cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com