Steel rail surface modification antirust welding device and rail surface fusing modification method

A surface modification and welding device technology, which is applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of equipment discomfort, temporary cure, non-concentration of heat, etc., and achieve fast welding process, easy operation, easy installation The effect of convenient layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

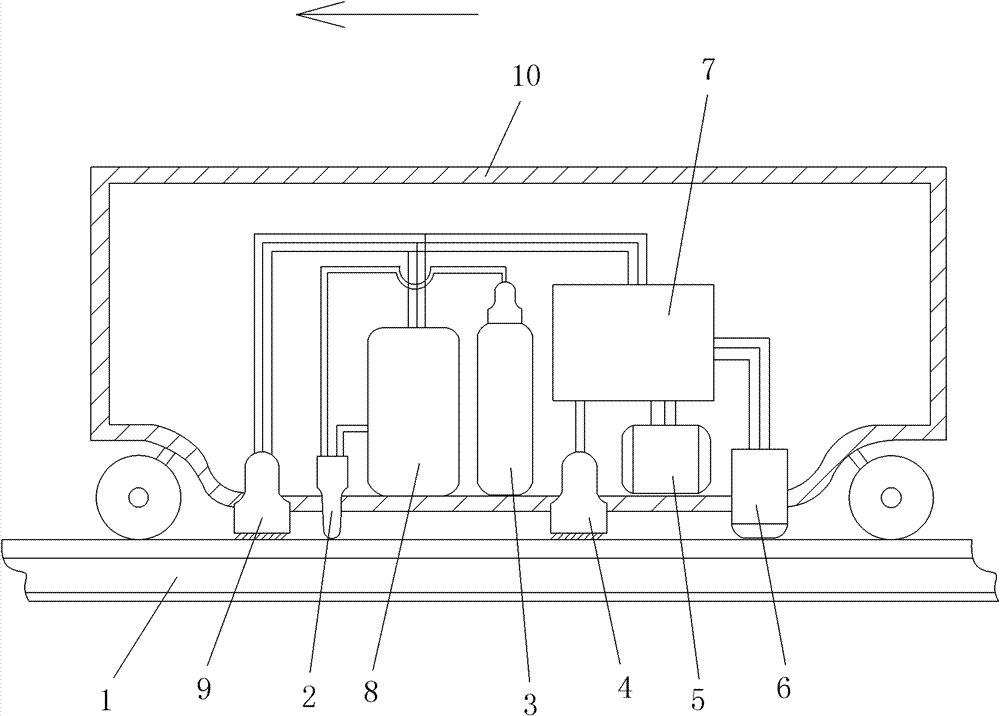

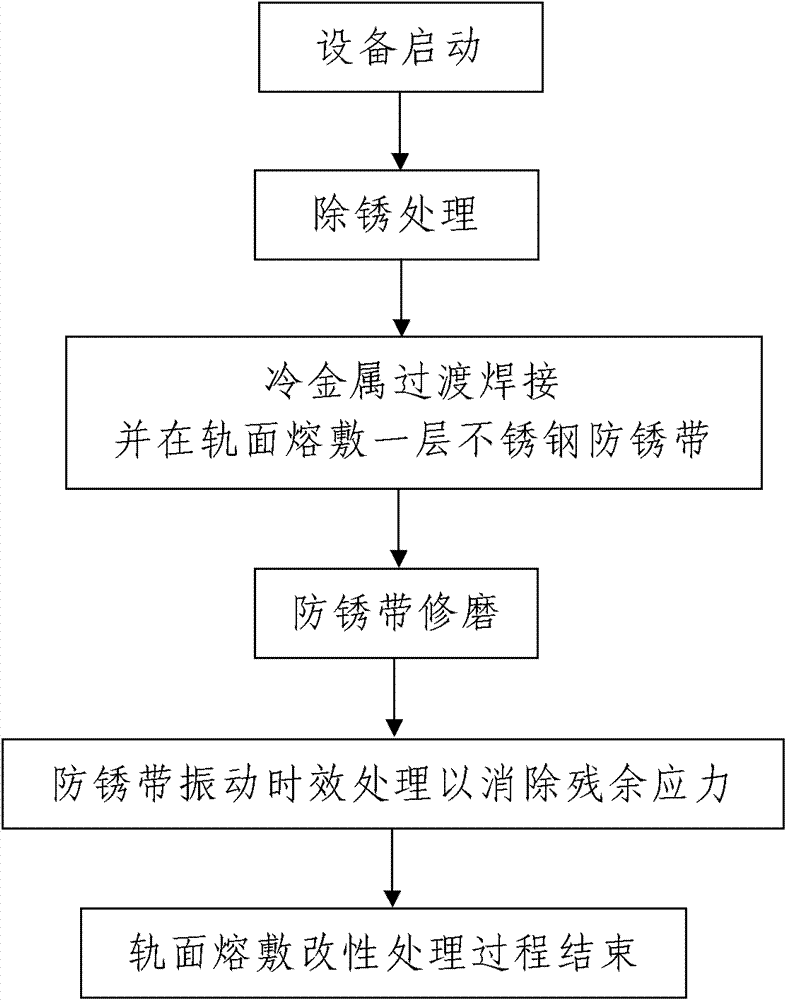

[0041] Such as figure 1 The shown a kind of rail surface modification anti-rust welding device comprises the rail car 10 that runs on the processed rail 1, the electric derusting machine tool 9 that derusts the rail surface of the processed rail 1, and after derusting A cold metal transition welding machine for depositing a layer of stainless steel anti-rust belt on the surface of the treated rail, an electric grinding machine 4 for grinding the surface of the stainless steel anti-rust belt, and the stainless steel anti-rust belt after grinding. Vibration aging device 6 for vibratory aging treatment on the rust belt surface and a power supply system for power supply for electric derusting equipment 9, cold metal transition welding machine, electric grinding machine 4 and vibration aging device 6, said power supply system is connected with electric derusting device 6 respectively Rust tool 9, cold metal transition welding machine, electric grinding machine 4 and vibration aging...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com