Sleeper evenly arranging device and evenly arranging construction method used for group-sleeper-type sleeper laying unit

A sleeper and driving device technology, which is applied in the direction of laying track, track, track maintenance, etc., can solve the problems of complex structure design of sleeper transmission mechanism, easy damage of sleeper mechanism parts, large impact of sleeper mechanism, etc., and achieves obvious advantages in market competition , Reliable work, and the effect of eliminating shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

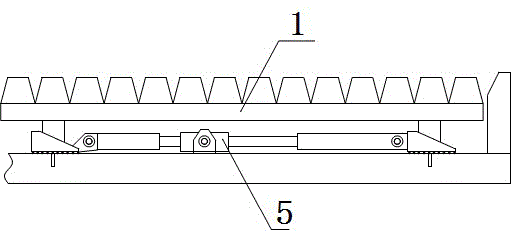

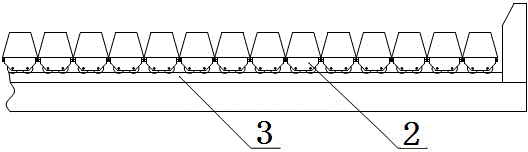

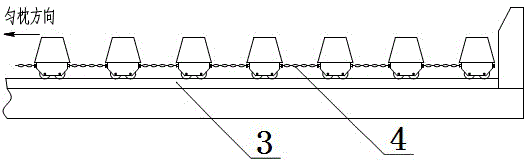

[0025] A sleeper leveling device for group sleeper track laying units, such as Figure 1 to Figure 3 As shown, it includes: a bracket 1, a pillow-sharing trolley 2, a running track 3, a chain 4 and a chain driving device. The support 1 is composed of two parallel steel sections with a certain distance, and its function is to temporarily support the sleeper (the fulcrum is close to both ends of the sleeper). ) Type II or Type III concrete sleepers are placed side by side. The sleeper can be raised or lowered with the support by moving the piston rod of the hydraulic cylinder 5 at the bottom of the support 1. After the support is raised, the sleeper trolley 2 can enter the two The space under the sleeper temporarily supported by the root bracket, the number of sleeper trolleys 2 is N, and each sleeper trolley carries a sleeper, which can travel back and forth along the running track 3, and the adjacent two sleeper workshops pass through the chain 4 The "soft" connection can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com