Bus bar leveling equipment for photovoltaic assembly

A technology of photovoltaic modules and bus bars, applied in photovoltaic power generation, electrical components, semiconductor devices, etc., can solve problems such as low production efficiency, high labor intensity of workers, and difficulty in guaranteeing the effect of manual leveling operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

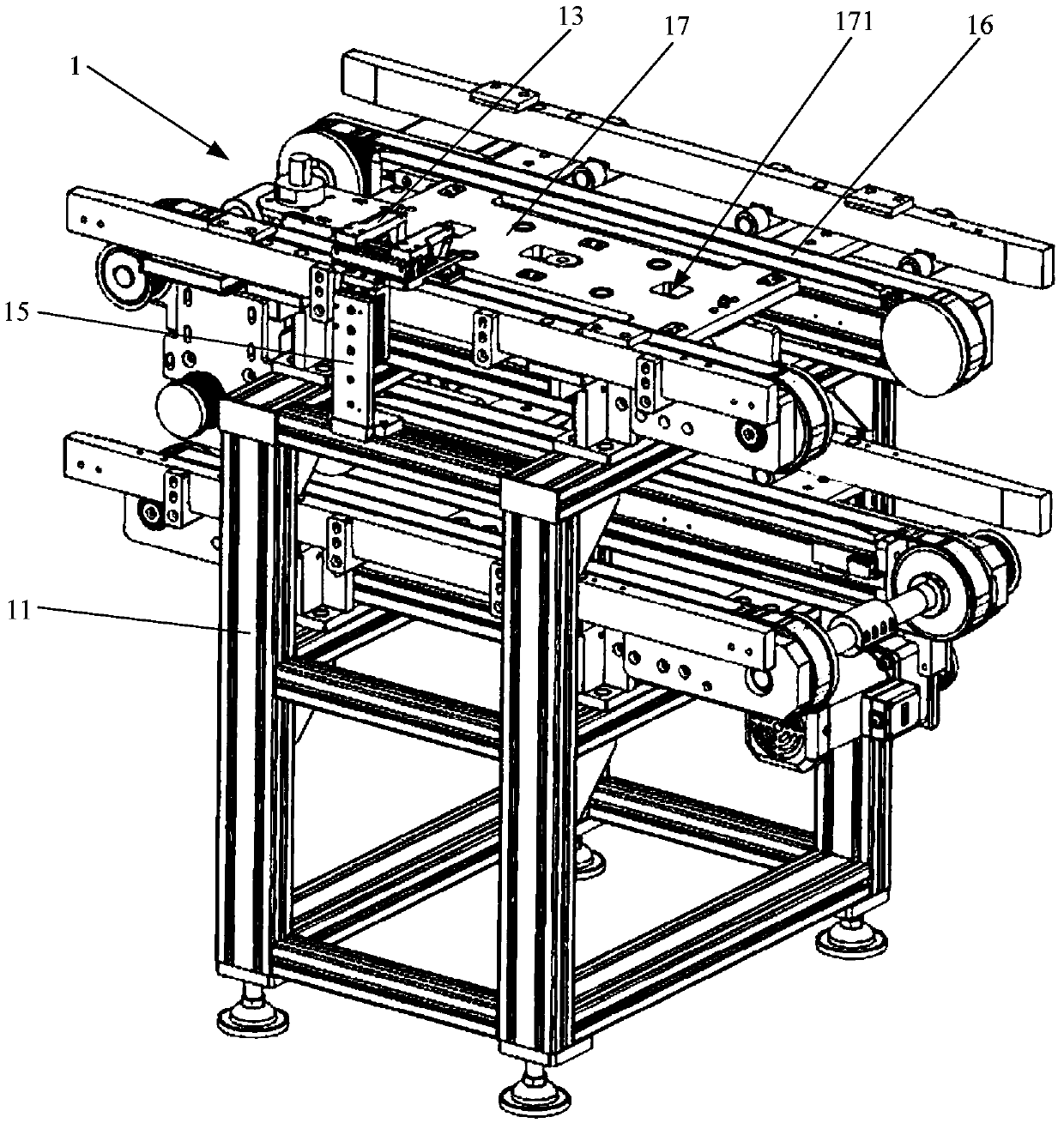

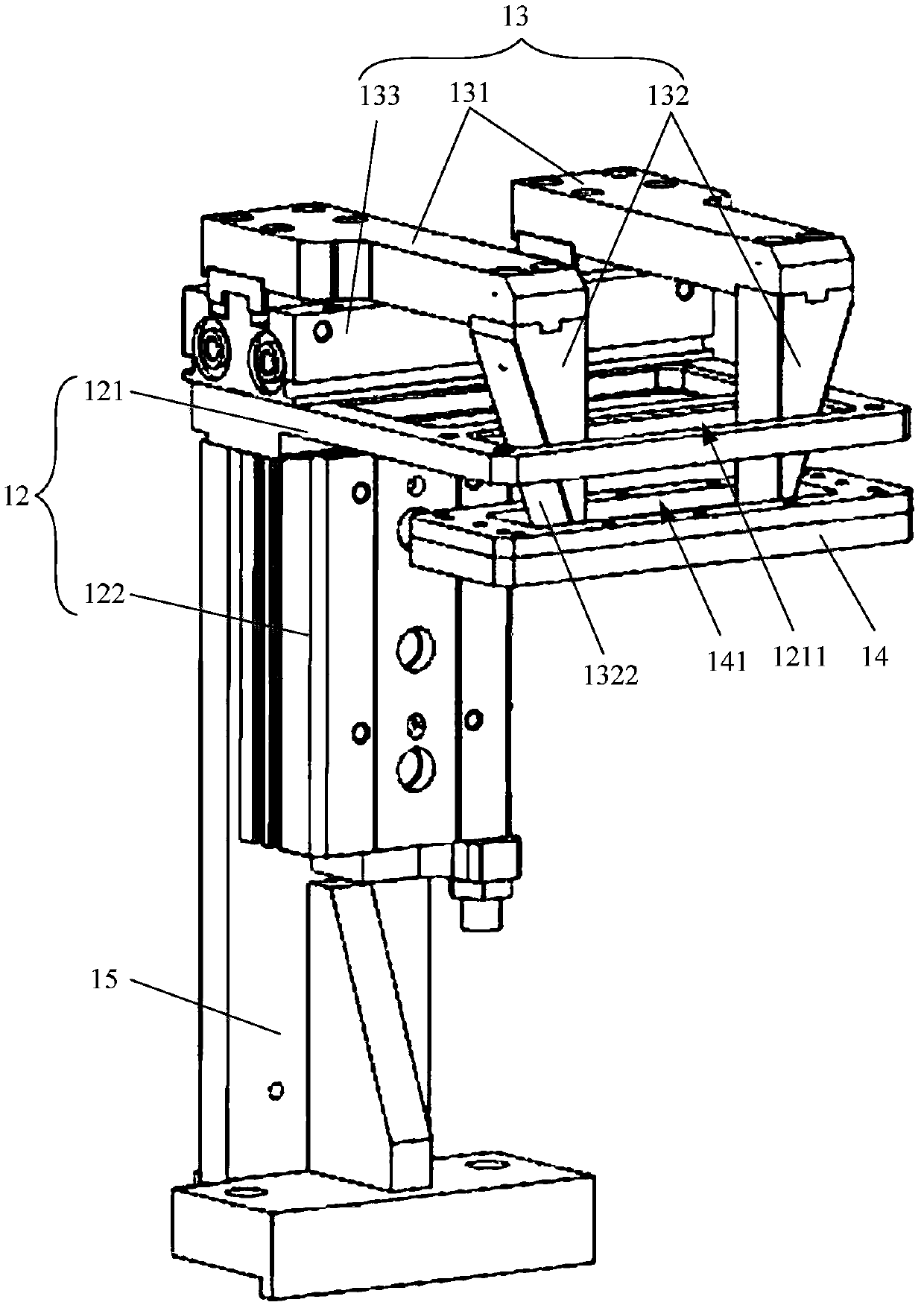

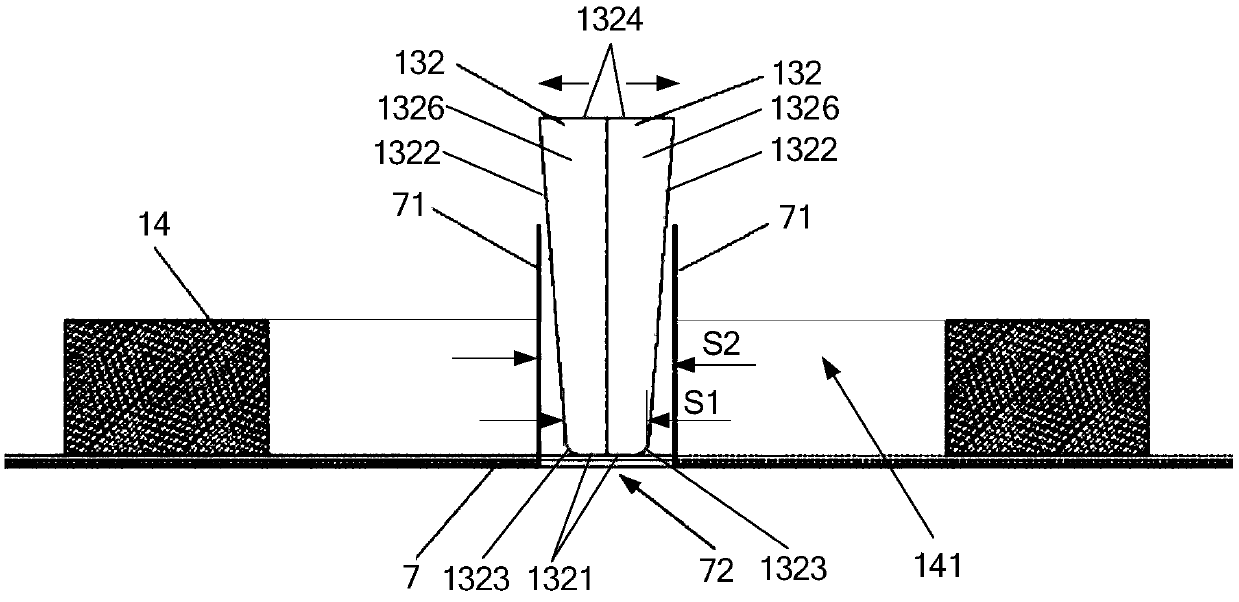

[0028] Such as figure 1 with figure 2 As shown, Embodiment 1 of the present invention provides a bus bar leveling device 1 for photovoltaic modules, including a base 11 , a lifting platform 12 , a bus bar leveling component 13 and a fixing device 14 . The base is used to support the bus bar leveling assembly. The lifting platform 12 is installed above the base 11 and can move up and down relative to the base 11 . The bus bar leveling assembly 13 is installed on the lifting platform 12 and is configured to bend the bus bar 71 and lay it on the back of the back plate of the photovoltaic module to be processed. The fixing device 14 is installed on the lifting platform 12 and configured to fix the photovoltaic module to be processed. The bus bar leveling assembly can be aligned with the lead-out hole (the bus bar of the photovoltaic module to be processed protrudes from the lead-out hole), and the size of the end of the bus bar leveling component close to the lead-out hole is ...

Embodiment 2

[0060] The difference from the first embodiment is that the bus bar leveling component includes a parallel moving component and a leveling block, and an air blowing device (not shown), and the other structures are the same as the first embodiment. The blowing device is connected to the support plate 121 of the lifting platform 12 and is located below the support plate 121 . Optionally, the air blowing device includes two air nozzles, and the two air nozzles are arranged near the rounded corner 1323 . Two air nozzles can be inserted between the two bus bars 71 , and the two air nozzles face in different directions to spray air to the bus bars located on both sides of the outlet hole respectively. For example, the two gas nozzles are arranged parallel to the lower end surface 1321 of the leveling block facing opposite directions, and may also be arranged at a certain angle with the lower end surface 1321 of the leveling block. Thus, the bus bar 71 on the left is inclined toward...

Embodiment 3

[0067] Different from Embodiment 1, the lower end surfaces of the two flattening blocks 132 are planes, and the ends of the two planes away from each other are provided with guide rollers (not shown).

[0068] Two leveling blocks 132 are arranged left and right, wherein the left end of the lower end surface of the leveling block 132 on the left is provided with a guide roller, and the right end of the leveling block 132 on the right is provided with a guide roller. When laying the bus bar 71 , the leveling block 132 on the left side moves horizontally toward the left side, and the leveling block 132 on the right side moves horizontally toward the right side. The guide roller can play a role similar to that of the rounded corner 1323, and can prevent the bus bar 71 from warping after being flattened.

[0069] The bus bar leveling equipment provided by the embodiment of the present invention has the following beneficial effects:

[0070] 1. Realize the automatic operation of bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com