Output shaft sealing device

A sealing device and output shaft technology, applied in the direction of engine sealing, transmission parts, bearing components, etc., can solve the problems of incompleteness, weakened sealing effect, oil mist leakage, etc., to achieve better sealing effect and restrain oil mist. The effect of improving the seepage and sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

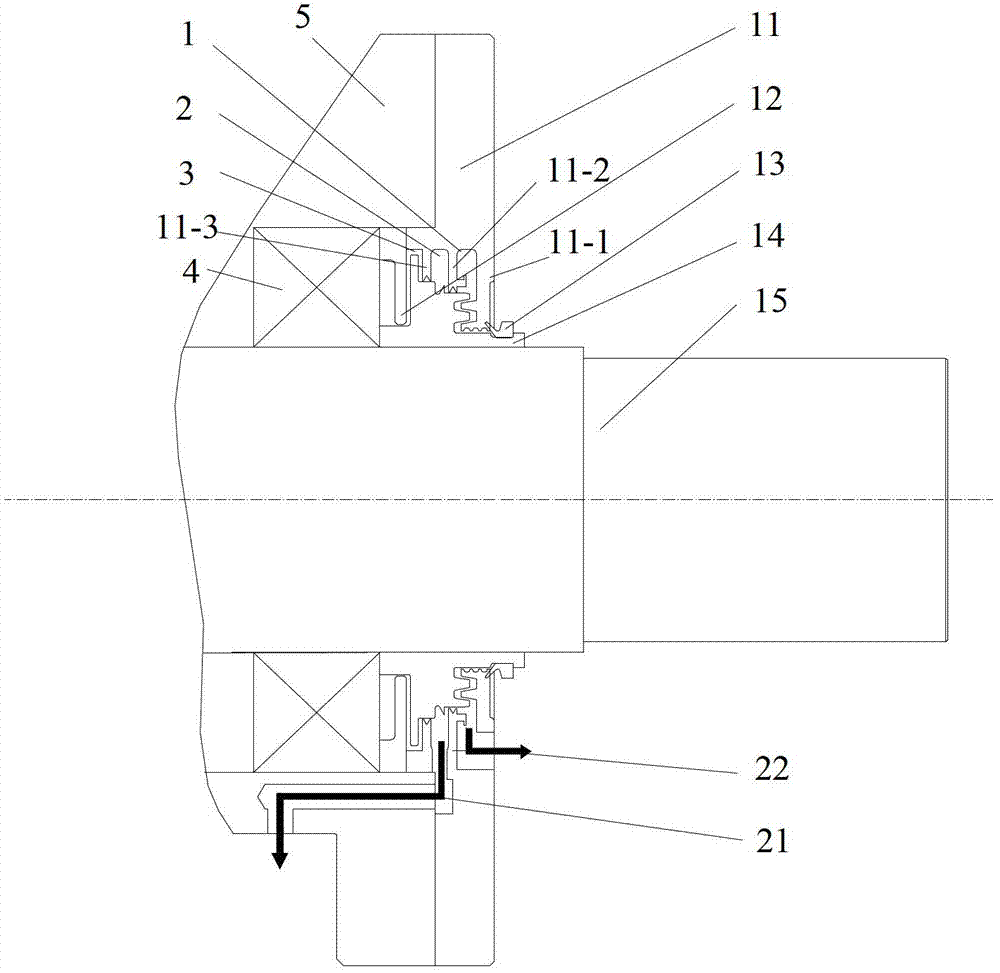

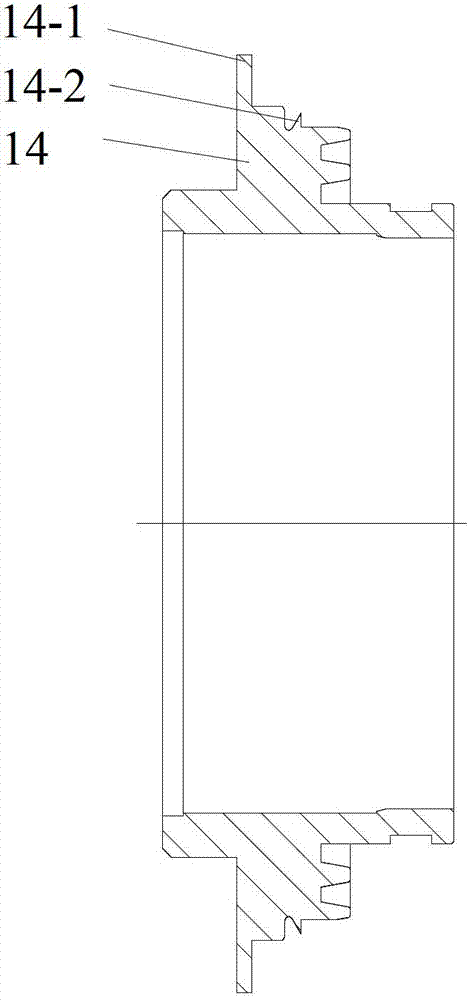

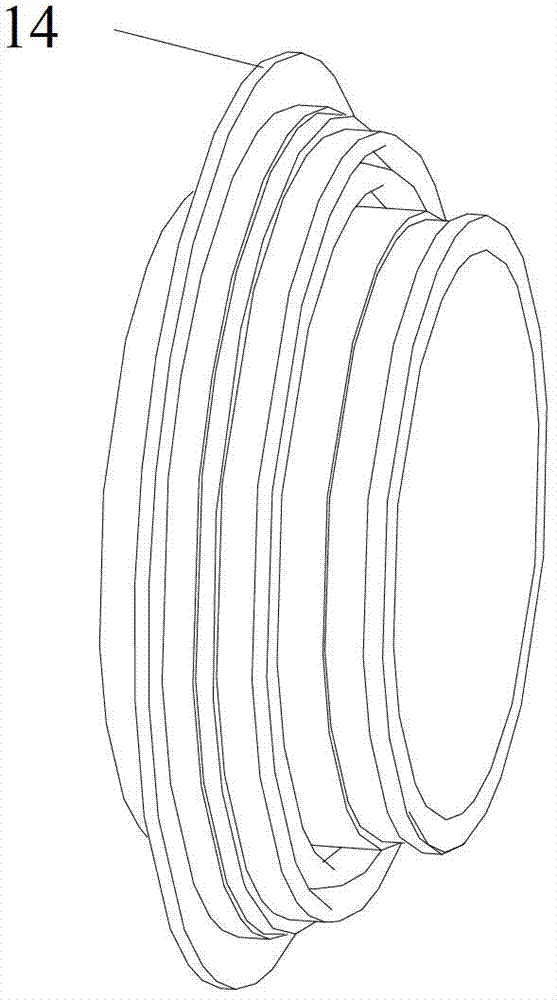

[0023] This embodiment is a wind power gearbox output shaft sealing device, the basic structure is as follows figure 1 shown (see Figures 2 to 9 ), including a sealing end cover 11 fixed on the outer end of the output hole of the box body 5, and a high-speed output shaft 15 supported in the output hole bearing 4 and passing through the sealing end cover 11 . The output shaft 15 is fixedly connected with the labyrinth inner ring 14 located in the inner hole of the sealing end cover 11 . The inner hole of the sealing end cap 11 has an outer blocking wall 11-1, a middle blocking wall 11-2, and an inner blocking wall 11-3 extending radially inward. Between the outer blocking wall 11-1 and the middle blocking wall 11-2 and between the middle blocking wall 11-2 and the inner blocking wall 11-3 respectively form an annular groove-shaped third oil return chamber 1 and a second oil return chamber 2 . The output hole is embedded between the oil deflector ring 12 outside the bearing a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com