Burner outer flame cover

A technology for an outer fire cover and a burner, applied in the field of the outer fire cover, can solve the problems of difficult cleaning, clogging of the main fire channel or the flame stabilization channel by overflow liquid, and the flame stabilization effect is not in the best state. Even combustion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

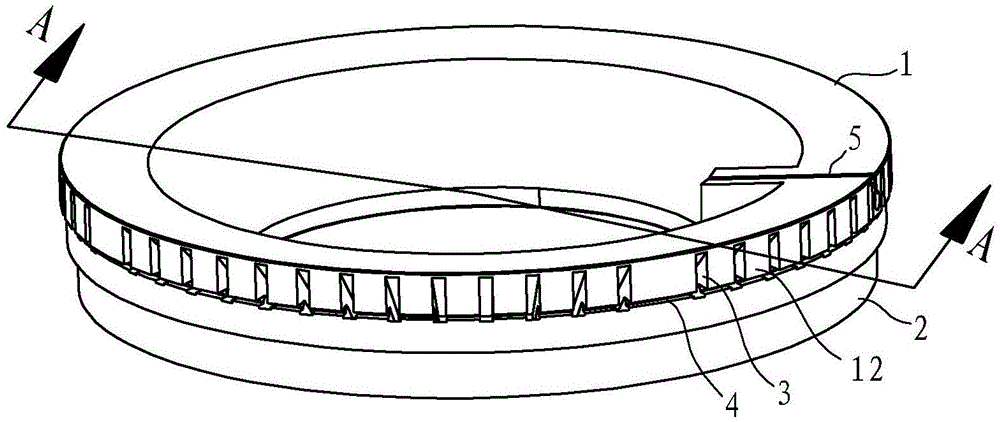

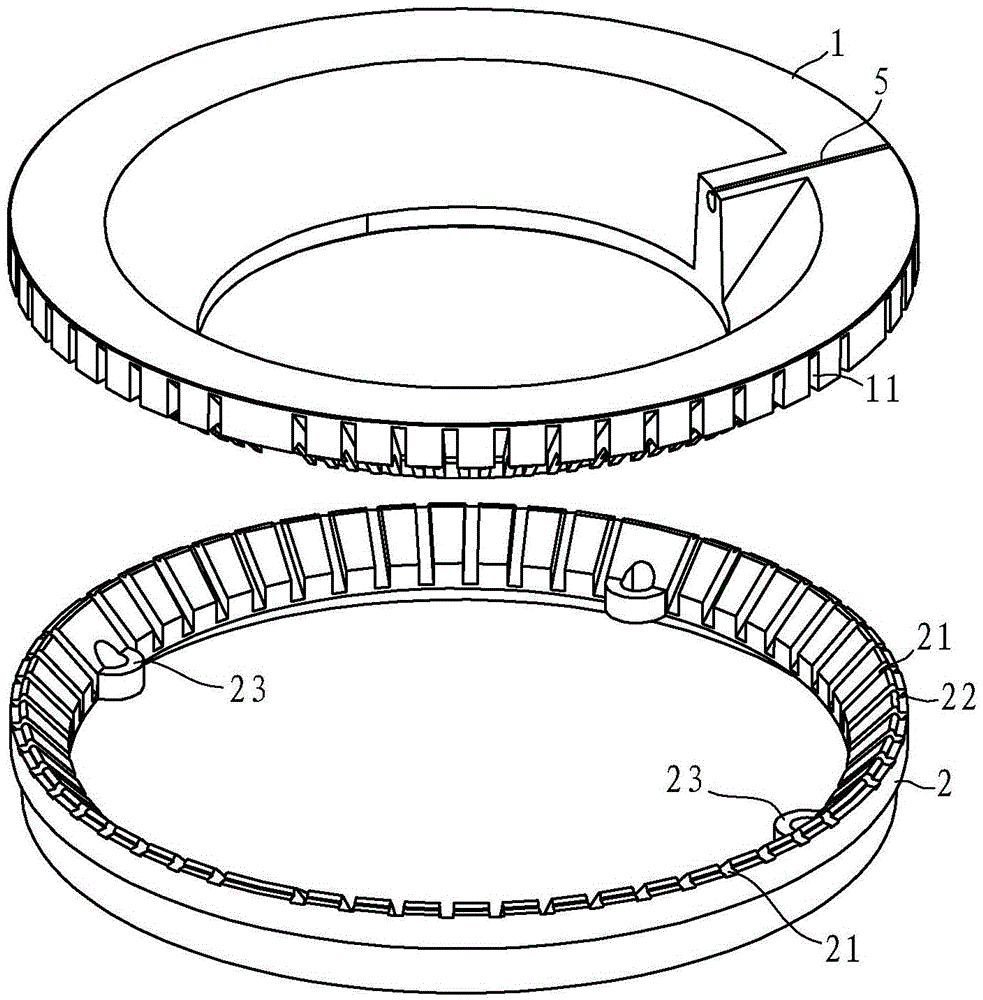

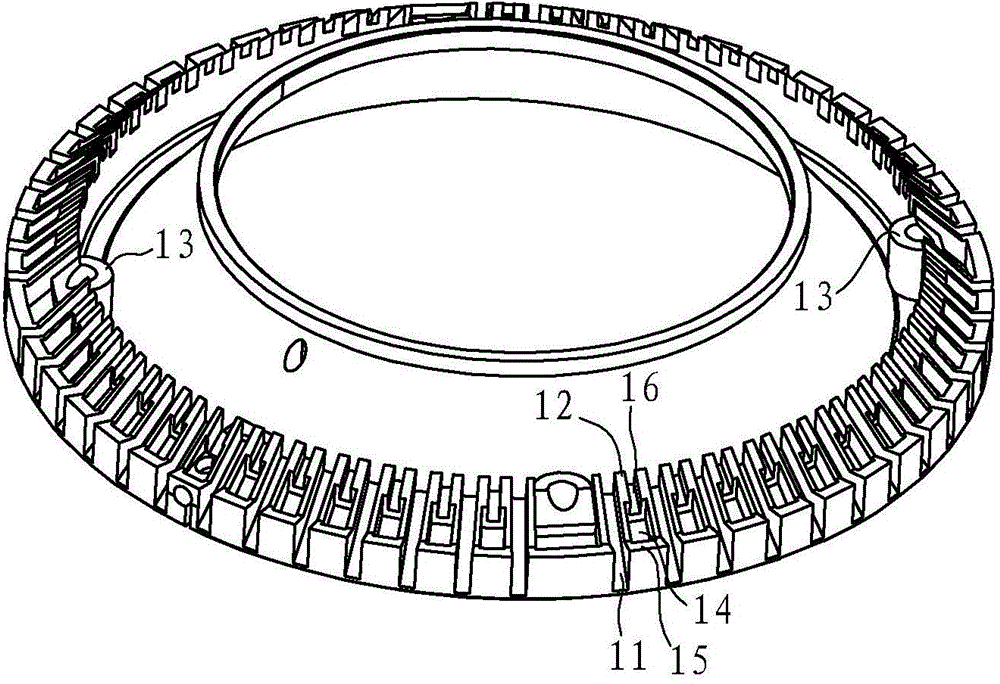

[0028] Example 1, such as Figure 1 to Figure 6 As shown, the burner outer fire cover in the present embodiment comprises an annular fire cover upper body 1 and a fire cover lower body 2, the fire cover upper body 1 is located above the fire cover lower body 2, and the fire cover upper body 1 A plurality of main fire grooves 11 are radially formed on the lower end surface around the circumferential direction, and spacers 12 are formed between adjacent main fire grooves 11 . The upper end surface of the fire cover lower body 2 is radially formed with a plurality of slots 21 around the circumferential direction. The slots 21 correspond to the main fire grooves 11 one by one to form the main fire channel. The main fire channel is gradually inclined from the inside to the outside. The outer facade of the fire cover forms the main fire hole 3, and the spacer 12 bottom surface of the fire cover upper body and the upper end surface of the fire cover lower body 1 form a flame-stabiliz...

Embodiment 2

[0037] Example 2, such as Figure 7 As shown, there is no slot on the upper end surface of the fire cover lower body 2 in the present embodiment, that is, the section length of the main fire groove 16 is consistent with the section length of the main fire passage. Refer to Example 1 for other structures.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com