Helicopter automatic inclinator spherical hinge bearing comprehensive fatigue testing machine

A technology of automatic tilter and fatigue testing machine, which is applied in the direction of mechanical bearing testing, etc., can solve the problems of large volume, energy consumption, structure, stability, etc., and achieve the effect of good high-speed motion stability, low energy consumption, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

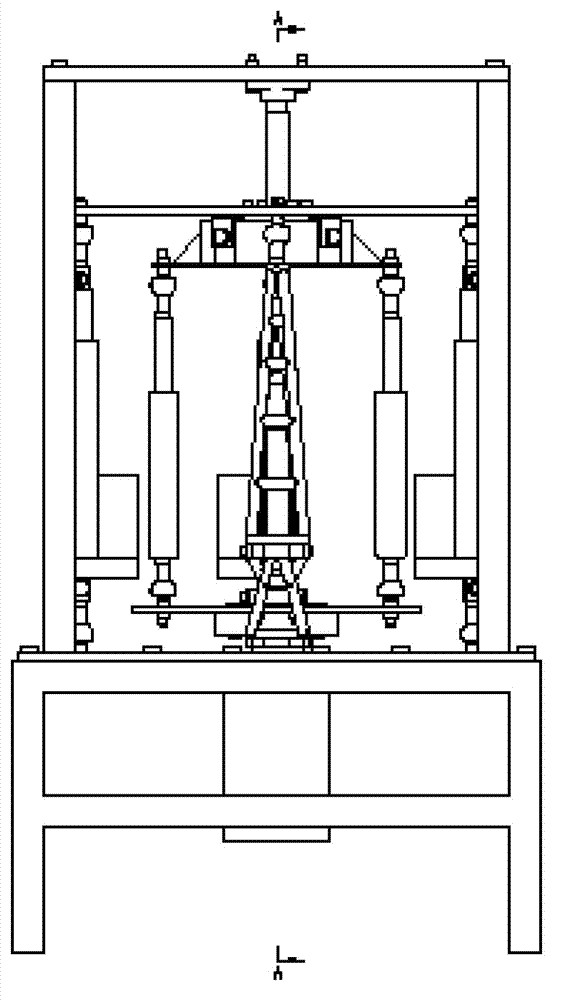

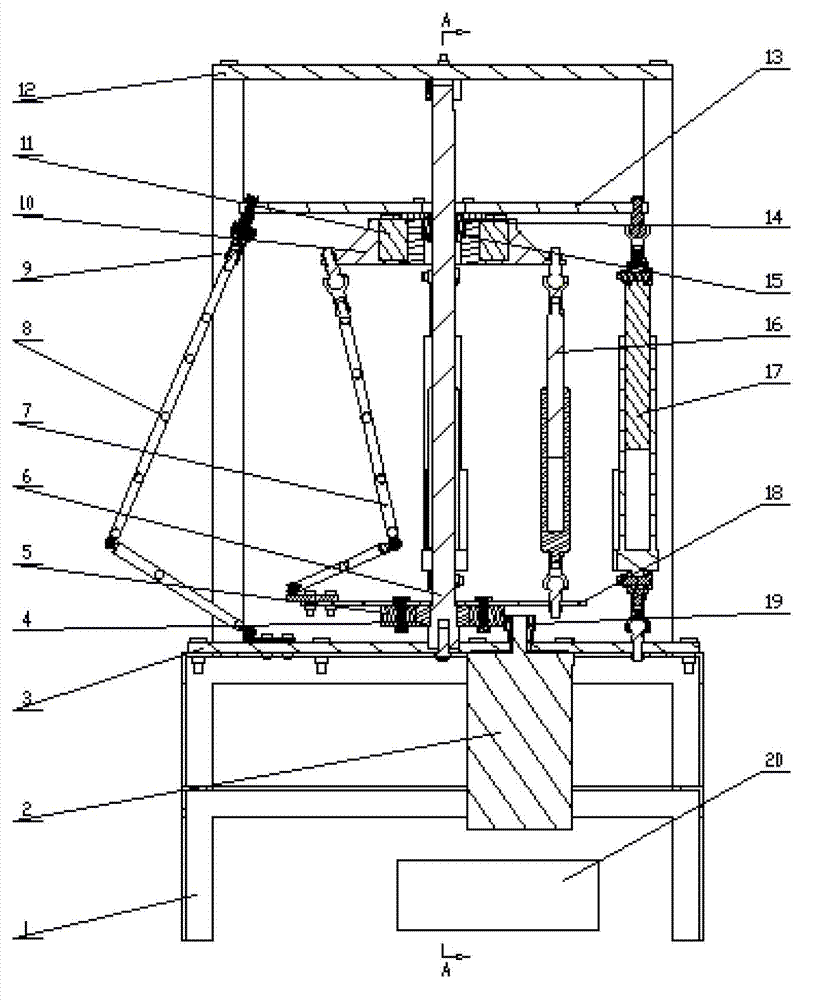

[0012] figure 1 and figure 2 Shown is the structural diagram of the comprehensive fatigue testing machine for the spherical hinge bearing of the helicopter automatic tilter. The present invention includes a bracket 1, a base 3, an inner ring parallel mechanism, an outer ring parallel mechanism, a power transmission mechanism and a control system 20, the base 3 is fixed on the bracket 1, and four columns 9 are equally divided on the same circumference of the base , a top cover 12 is provided on the top of the column 9, a main shaft 6 is provided between the base 3 and the upper cover 12, and the axis of the main shaft 6 is located at the center of the circle where the four columns 9 are located; The platform 13, the joint bearing 15, the first anti-twist arm 8, and the electric booster 17 are composed. The platform 13 on the inner ring is a circular platform that is centered on the main shaft, and there are three electric boosters 17, which are arranged on the Between the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com