Substrate processing apparatus, substrate processing method and storage medium

A technology of a substrate processing device and a substrate processing method, which is applied to chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc., can solve problems such as substrate pollution, foreign matter, gas, etc., and achieve the effect of keeping the environment clean

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

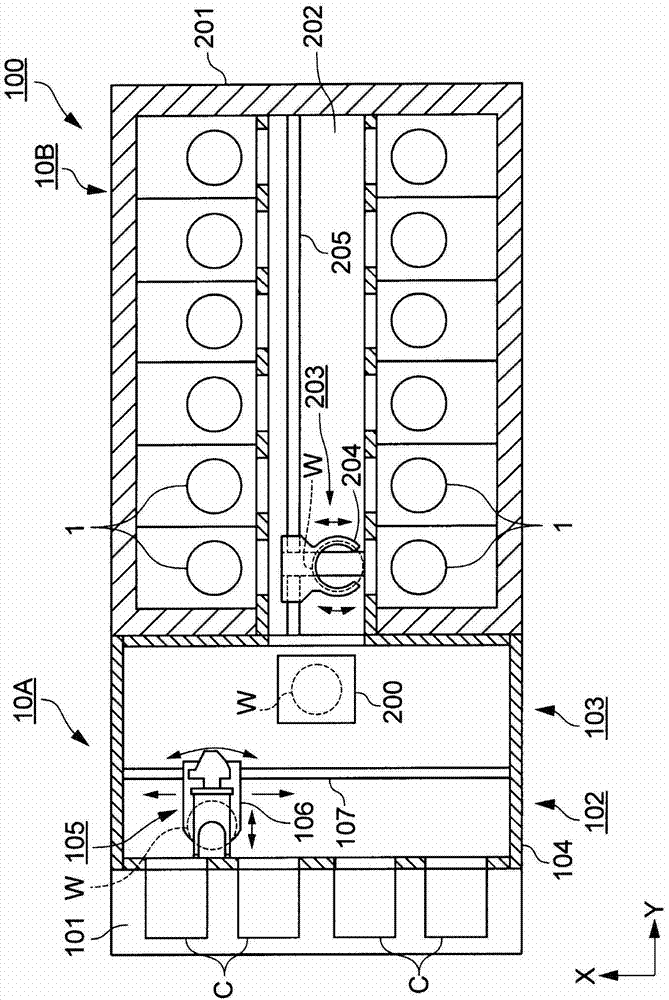

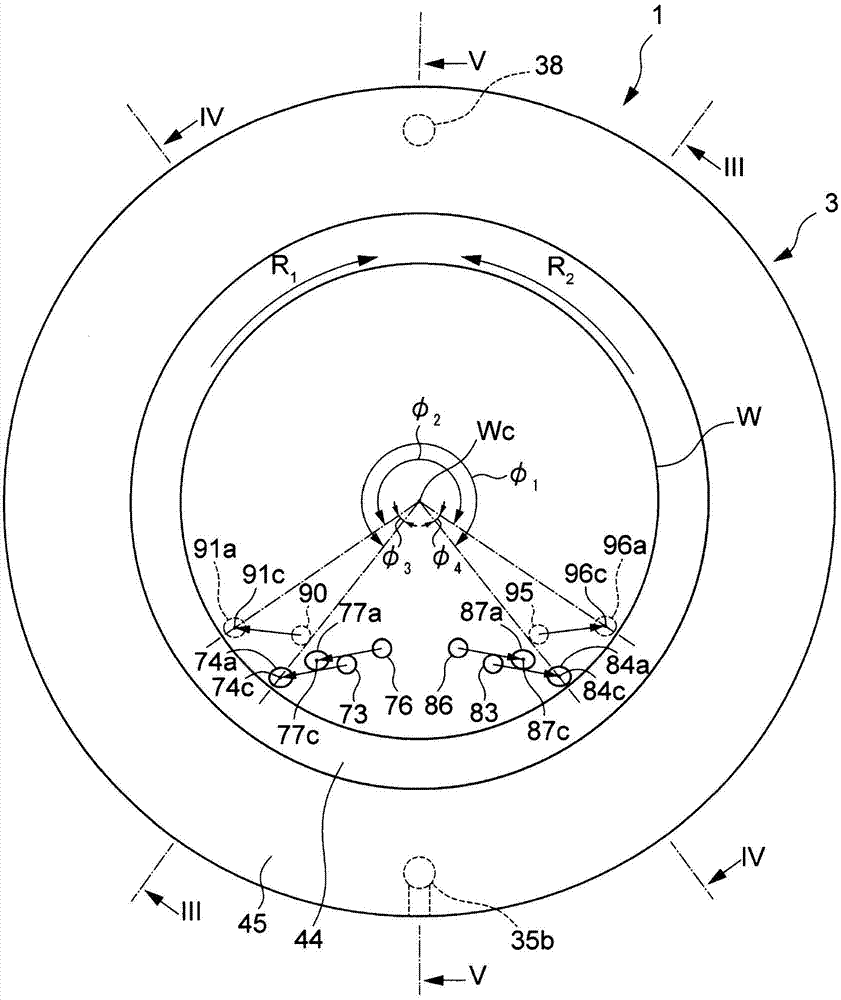

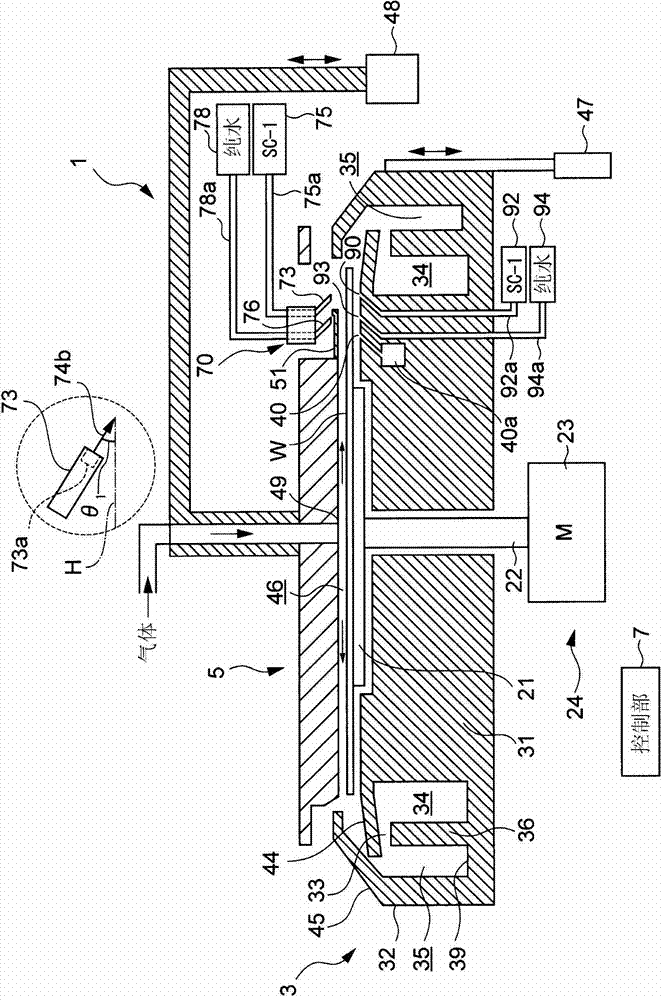

[0023] Below, refer to Figure 1 to Figure 10 Embodiments of the present invention will be described. Here, a substrate processing apparatus 1 for performing liquid processing on a semiconductor wafer (hereinafter, simply referred to as “wafer”) W that is a circular substrate will be described.

[0024] On the wafer W processed by the substrate processing apparatus 1 of the present embodiment, a film made of, for example, SiN is formed, and the film is formed continuously from the upper surface of the wafer W to the wafer W through the side end portion of the wafer W. The peripheral edge of the lower surface side of W. Here, the substrate processing apparatus 1 is configured to remove, among the films formed on the wafer W, the film located at the peripheral portion of the wafer W by supplying the wafer W with at least two different chemical solutions. First, refer to figure 1 , the substrate processing system 100 including such a substrate processing apparatus 1 will be de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com