Male Connectors and Electrical Connectors

A technology of electrical connectors and connectors, which is applied in the direction of connection, parts of connection devices, circuits, etc., can solve the problems of loose connections, affecting the connection of connection terminals, poor contact, etc., and achieve the effect of stable connection and quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

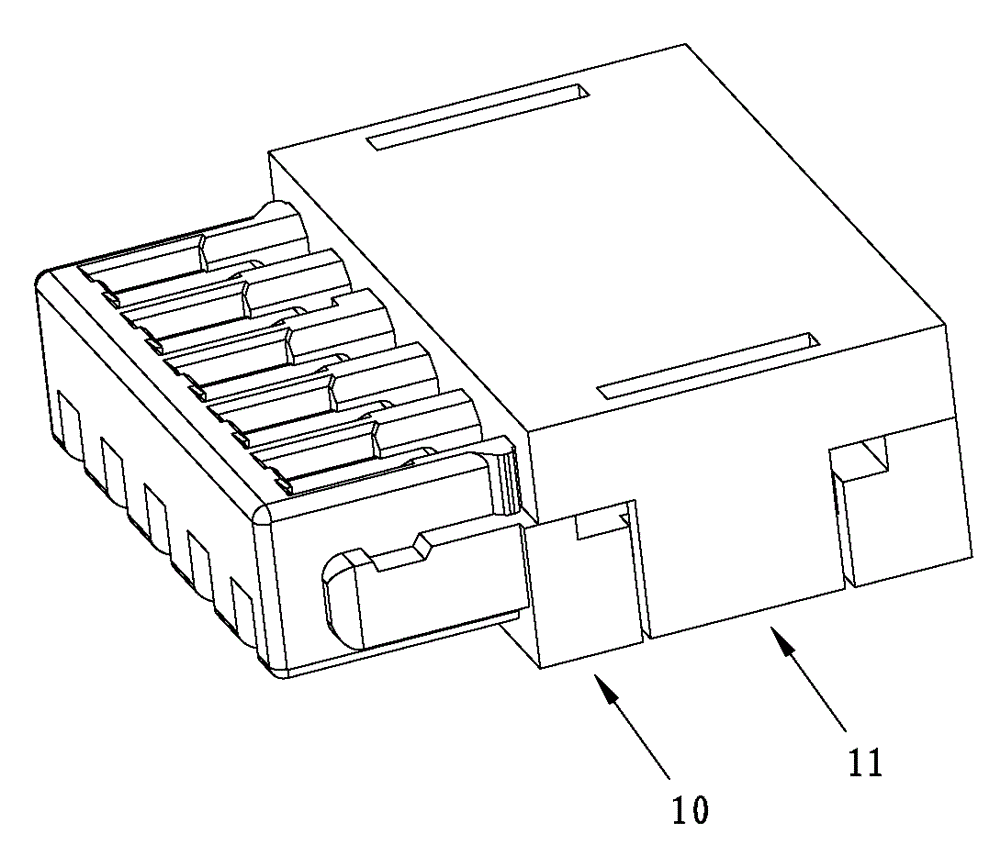

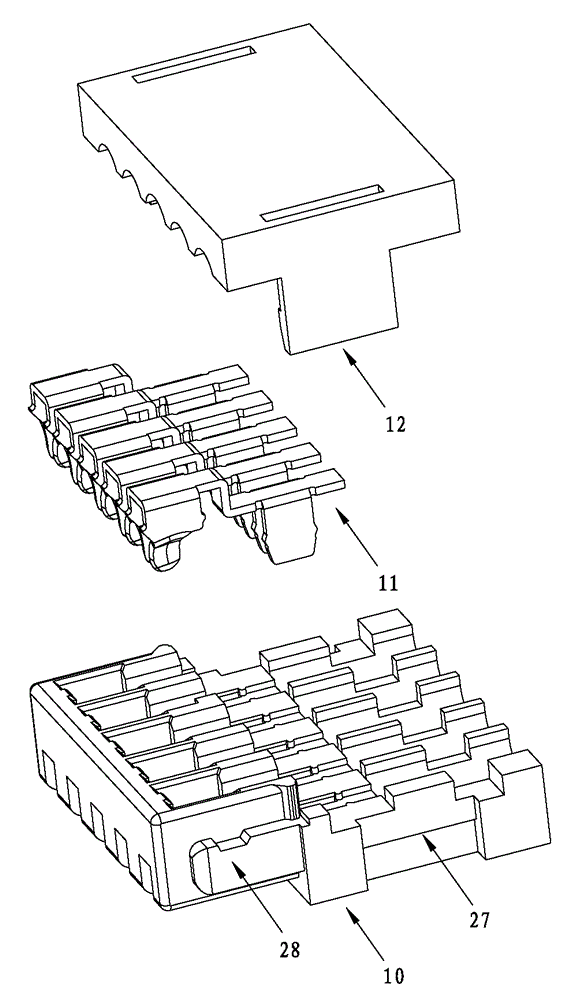

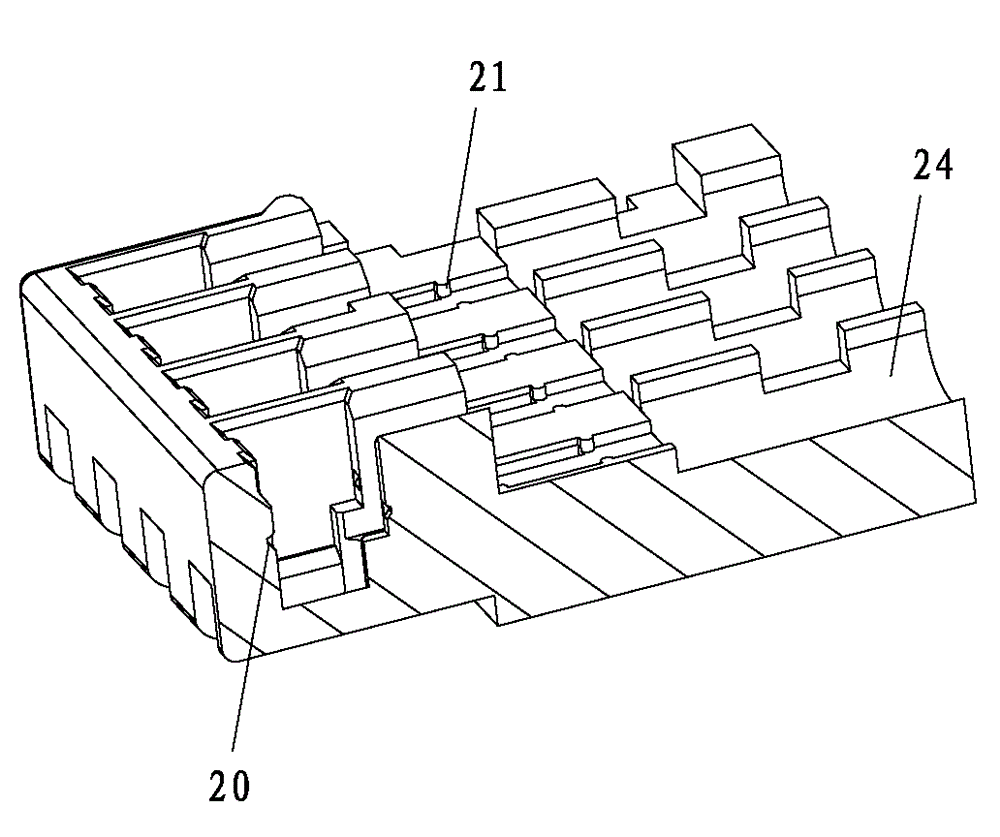

[0038] See Figure 1 to Figure 11 , the male connector of the electrical connector of this embodiment includes a rubber main body 10, a connection terminal 11 and a crimping cover 12, the connection terminal 11 includes a terminal body 13 bent into a z shape, and the z shape terminal body 13 Both sides of the front part of the terminal body 13 are stamped downward to form a connecting elastic piece 14, and the lower part of the connecting elastic piece 14 is bent inward to form a clamping part 15, and the middle part of the connecting elastic piece 14 Both sides of the terminal body 13 are provided with shrapnel protrusions 16, the rear part of the terminal body 13 is a welding part, and both sides of the rear part of the terminal body 13 are punched downward to form a fixed bracket 17, and both sides of the middle part of the fixed bracket 17 are There is a retainer protrusion 18, a positioning notch 19 is provided at the connection between the terminal body 13 and both sides...

Embodiment 2

[0055] See Figure 1 to Figure 13 , the electrical connector of this embodiment includes a female connector, and also includes the male connector of Embodiment 1, the female connector includes a conductive terminal 31 and a base 30 with an accommodating area, the conductive terminal 31 is connected to the base The seat 30 is plugged in, the two side walls of the accommodation area are provided with guide grooves 32, both sides of the front of the rubber body 10 are provided with guide blocks 28, the front of the rubber body 10 is inserted into the accommodation area, and the guide blocks 28 are embedded in the guide grooves 32 , the conductive terminal 31 penetrates into the accommodating groove and contacts with the connecting elastic piece 14 . When in use, the female connector is generally connected to the circuit board, while the male connector is generally connected to the wire core. The male connector is inserted into the female connector, and the contact between the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com