Connecting mechanism of pushing rod

A connecting mechanism and push rod technology, applied in hand-held lawn trimmers, etc., can solve the problems of unfavorable packaging, transportation and storage, increase the packaging space of the whole machine, and cannot be disassembled, and achieve simple structure and reduced packaging Volume, good for packaging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

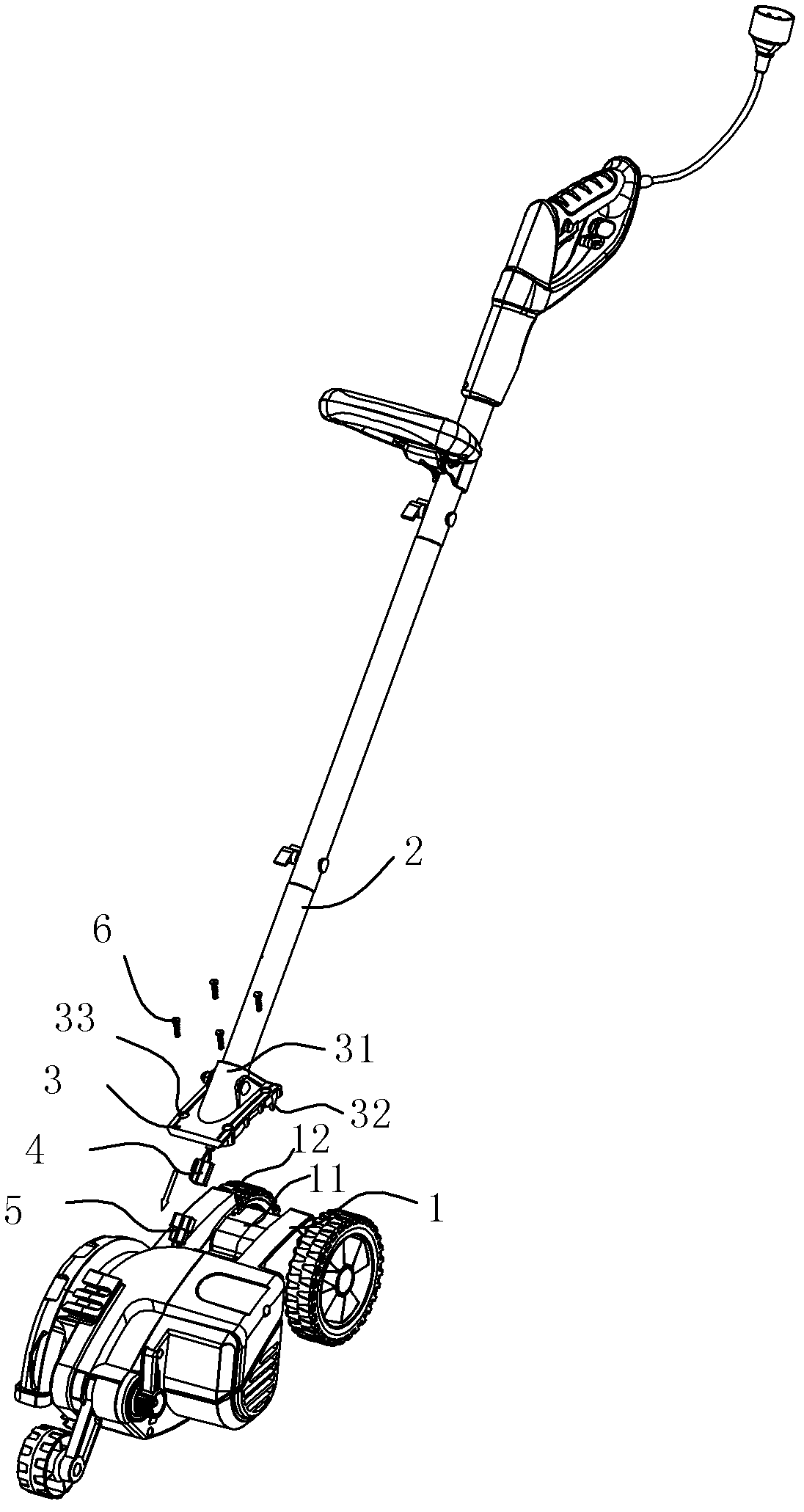

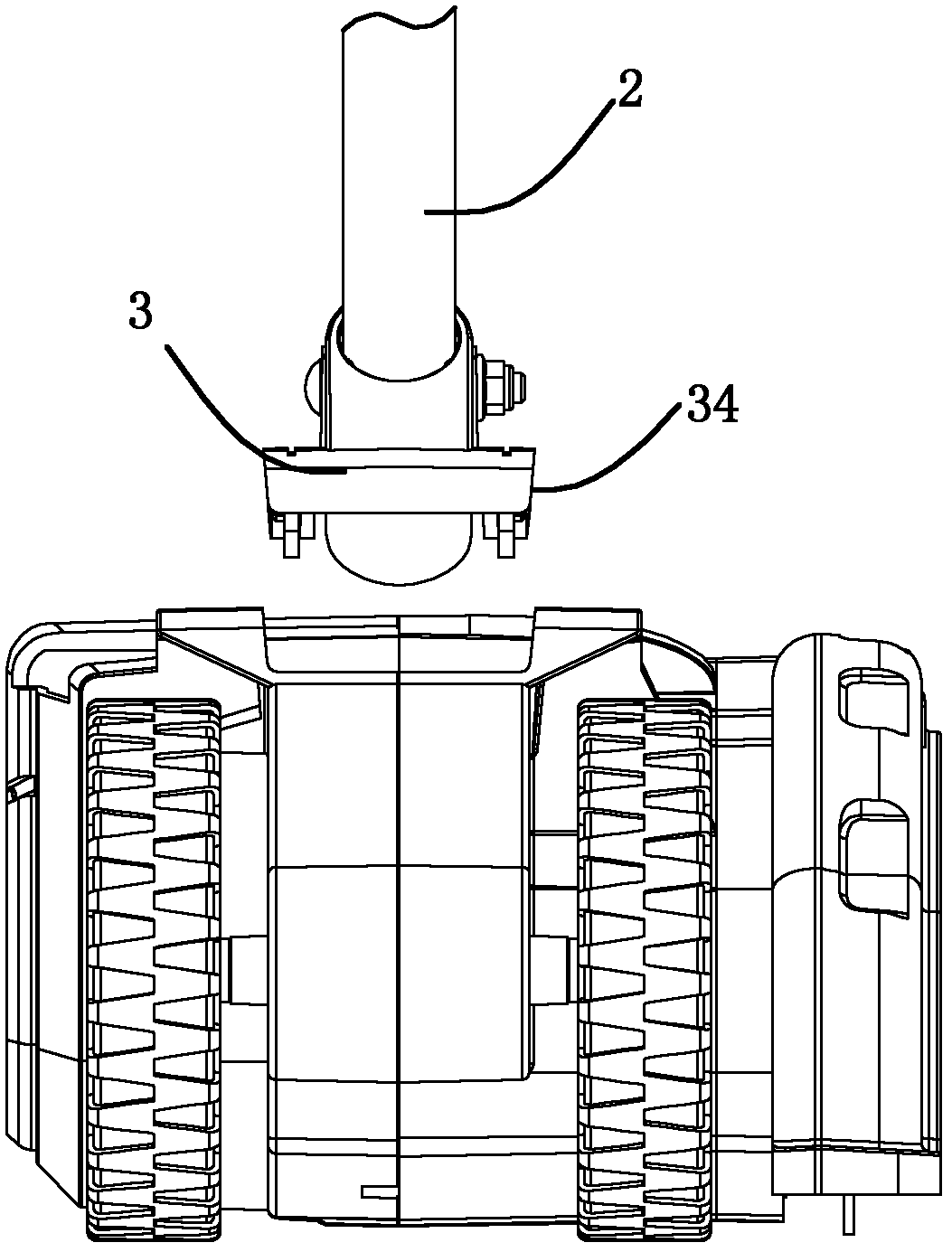

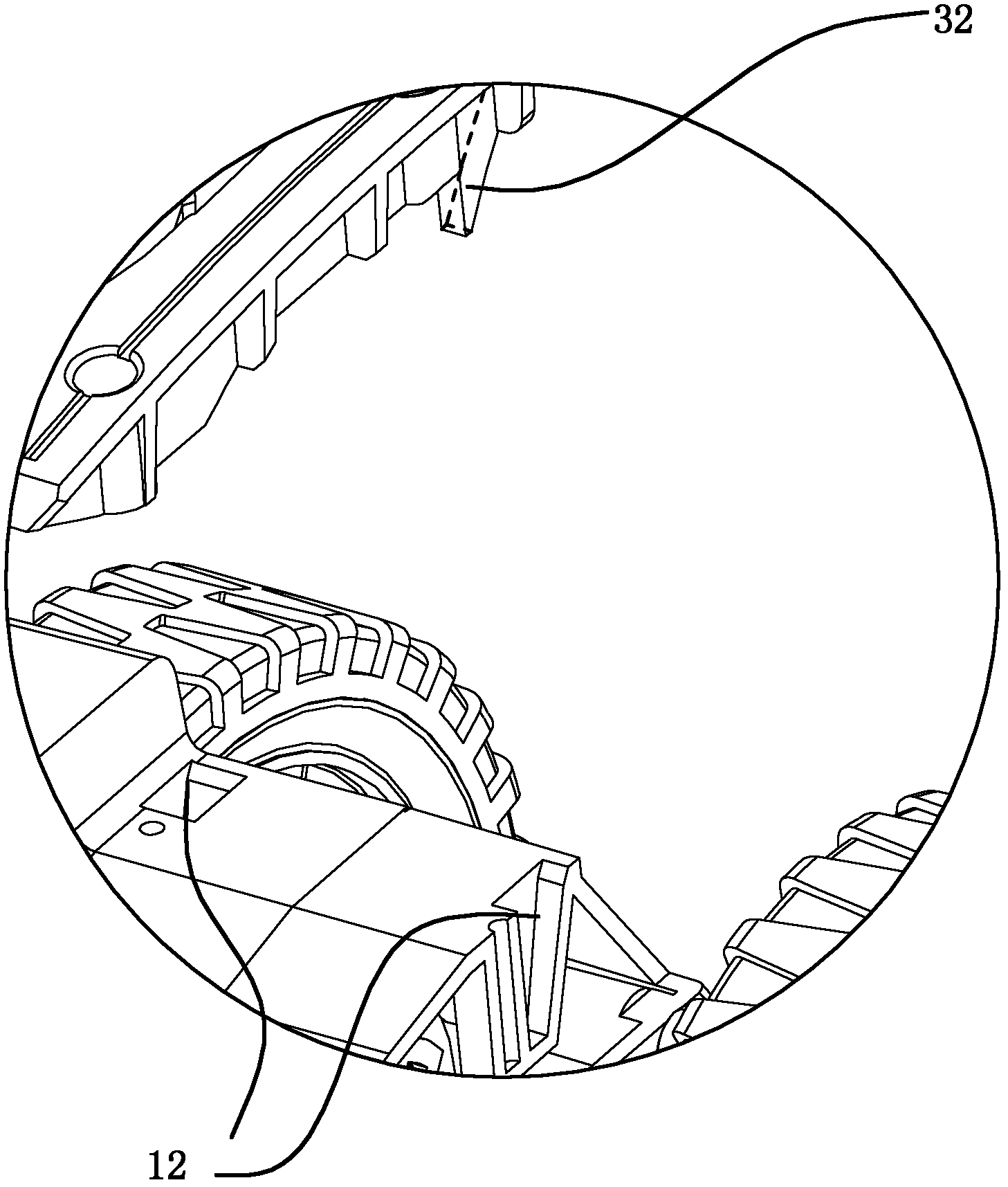

[0017] As shown in the figure, a push rod connection mechanism includes a fuselage body 1, a push rod 2, a two-wire composite socket 4 and a two-wire composite plug 5 for connecting electrical circuits, and the two-wire composite socket 4 is located below the push rod 2 , the second-wire composite plug 5 is arranged on the main body 1 of the fuselage, and the second-wire composite socket 4 and the second-wire composite plug 5 are plugged and set in the accommodation cavity of the fuselage main body 1, and the push rod 2 and the fuselage main body 1 are completed. The connection of the electrical circuit; the lower end of the push rod 2 is provided with a base 3, and the upper end of the base 3 is provided with a sleeve 31 which is socketed with the bottom of the push rod 1, and the base 3 is sleeved on the bottom of the push rod 2 , connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com