Cavity body inside three-dimensional ultrasound probe used in ultrasound medical equipment

A medical equipment, three-dimensional ultrasound technology, applied in the direction of catheter, surgery, etc., can solve the problem of inconsistency in intracavity images, etc., to achieve fast and accurate processing and real-time display, reliable structure, and uniform data collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to fully understand the technical content of the present invention, the technical solution of the present invention will be further introduced and illustrated below in conjunction with specific embodiments.

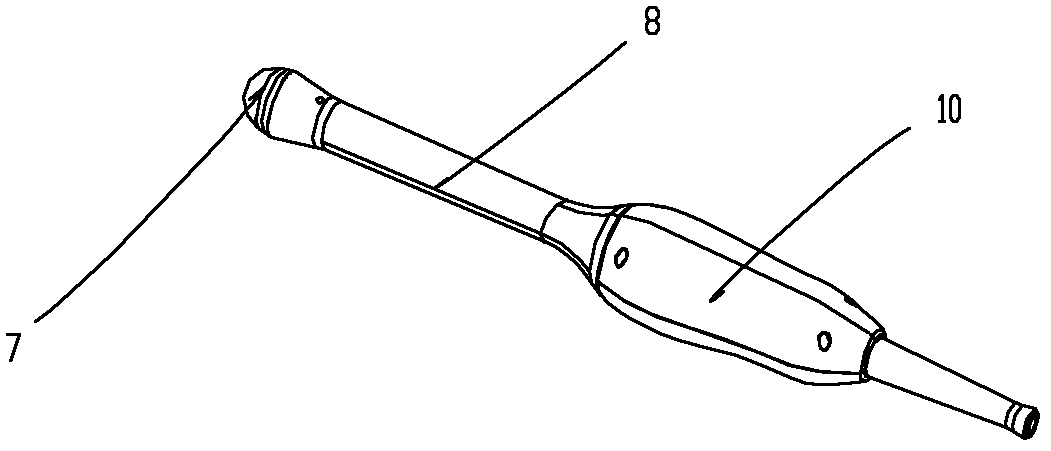

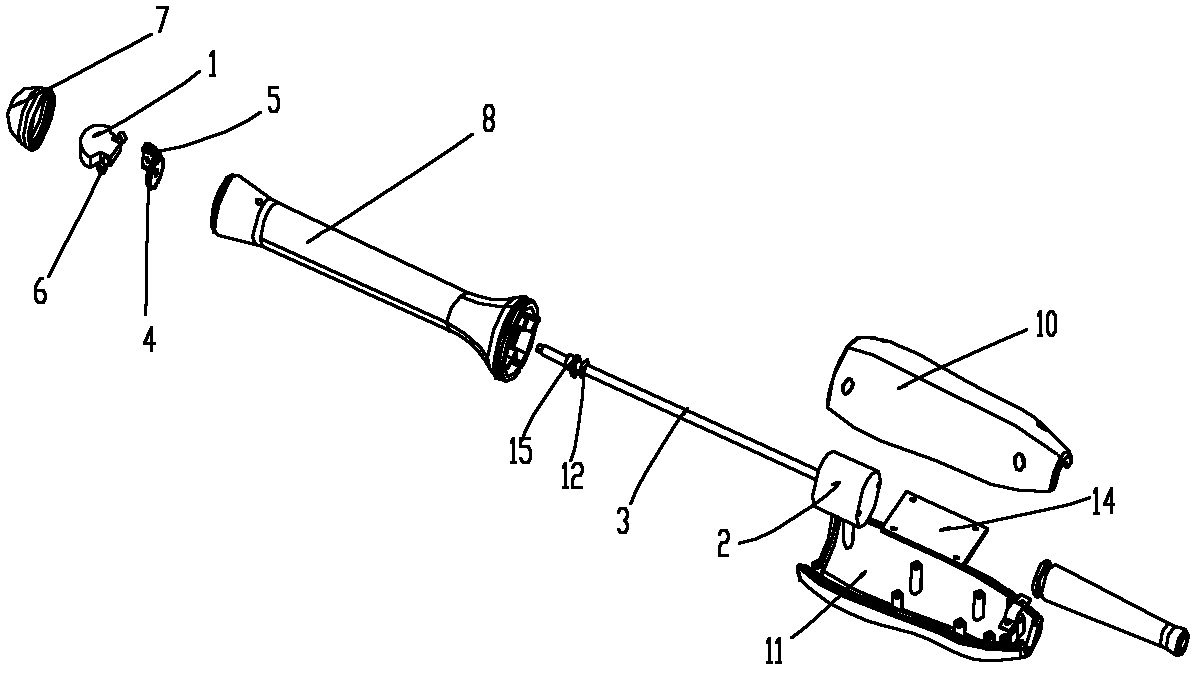

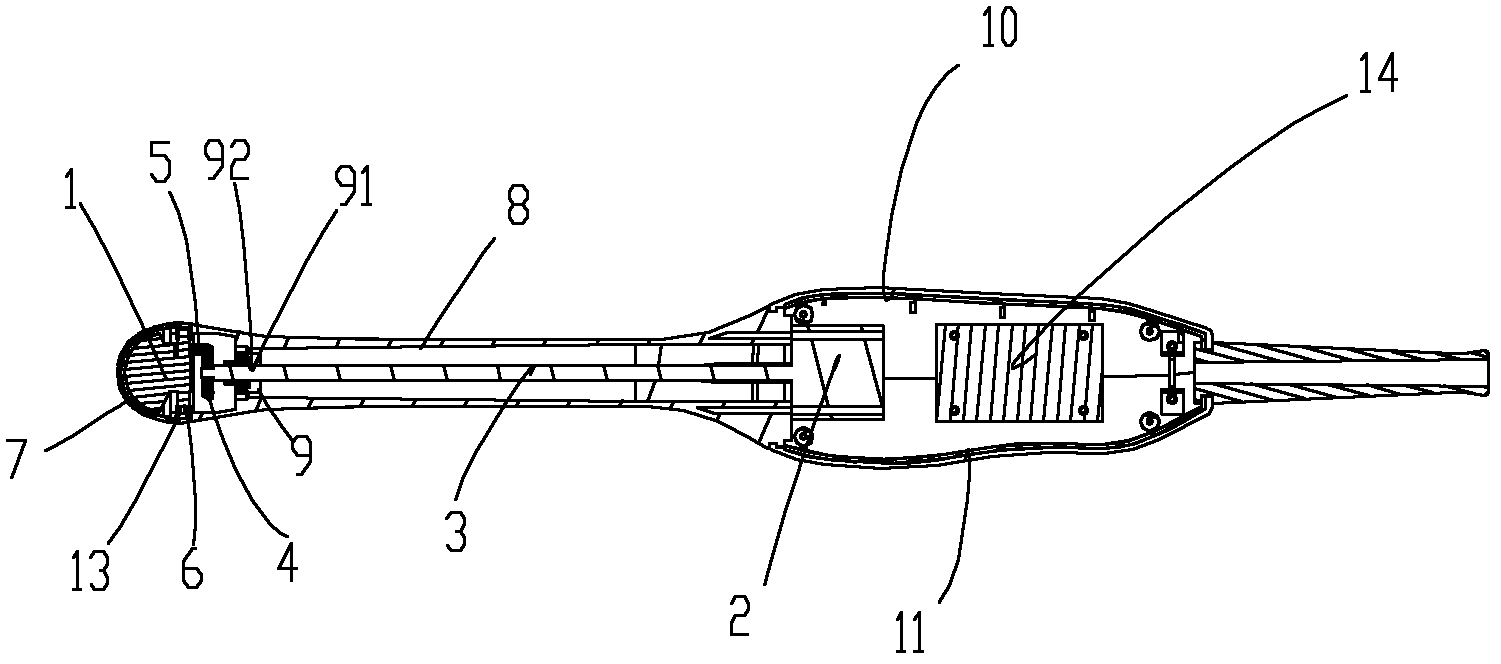

[0019] Such as figure 1 As shown, it is a schematic diagram of the three-dimensional structure of the present invention; as figure 2 Shown is a schematic diagram of the explosion structure of the present invention; as image 3 As shown, it is a cross-sectional view of the present invention, including an acoustic head 1 and an outer casing that seals the sound head, and a driving motor 2 electrically connected to the motor drive control device in the ultrasonic medical equipment is arranged in the outer casing, and the driving motor 2 The output shaft 3 is provided with a driving bevel gear 4, the sound head 1 is fixed on a rotating shaft 6 with a driven bevel gear 5, and the driving bevel gear 4 and the driven bevel gear 5 are meshed for transmission . ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap