Sleeve sliding roller

A technology of sleeve shaft and rolling device, which is applied in the field of installation and fastening device of rolling processing tools, can solve the problems of improper matching, high defective rate, difficult assembly and disassembly, etc., and achieves safe and reliable use, simple implementation and compact structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

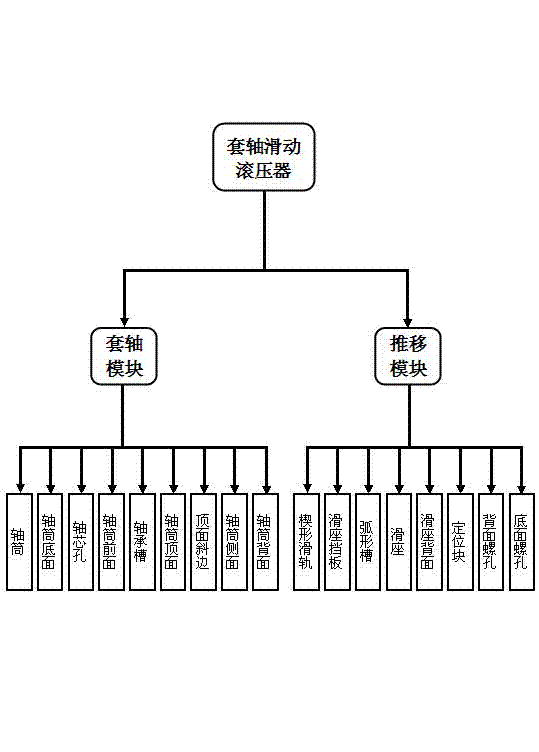

[0030] As a technical solution for product production, the present invention can be implemented through the organic combination of various components. Product organizational structure of the present invention such as figure 1 shown.

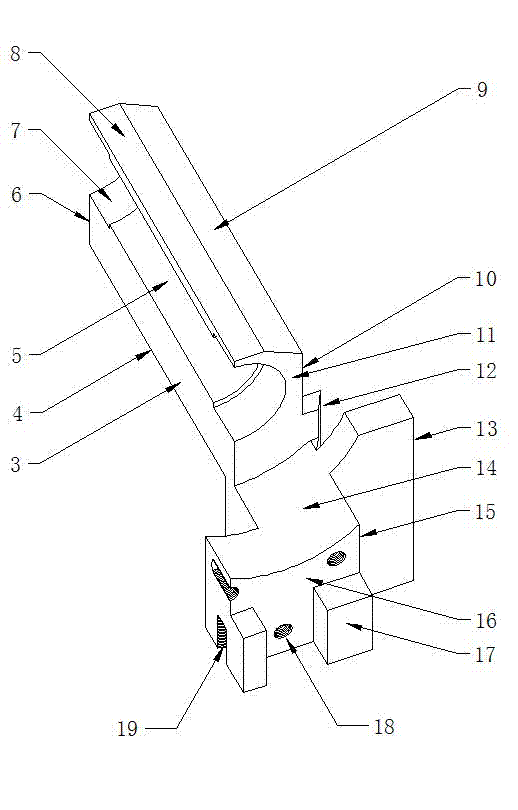

[0031] figure 1 Among them, the product of the present invention is composed of two modules, the sleeve and the push; wherein, the sleeve module structure includes the shaft cylinder, the bottom surface of the shaft cylinder, the shaft core hole, the front surface of the shaft cylinder, the bearing groove, the top surface of the shaft cylinder, and the inclined top surface The side, the side of the shaft cylinder, and the back of the shaft cylinder are composed of nine parts. The push module structure includes wedge-shaped slide rails, sliding seat baffles, arc grooves, sliding seats, sliding seat backs, positioning blocks, back screw holes, and bottom screw holes. component.

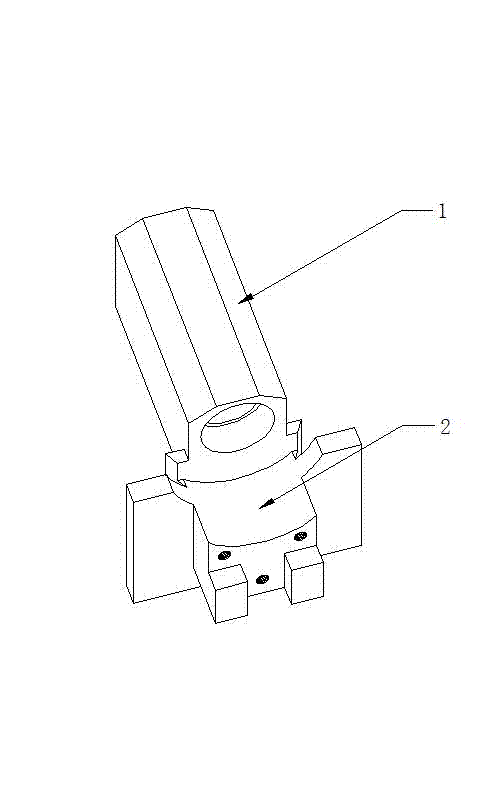

[0032] In the embodiment, the product module appearance struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com