Direct torrefied type molten aluminum filtering tank

A filter box and molten aluminum technology, which is applied in the field of continuous casting molten aluminum filtration, directly baked molten aluminum filter box, can solve the problem that the molten aluminum cannot be completely discharged, the preheating effect is poor, and the baking operation of the fine filter plate is not good. Safety and inconvenient problems, to achieve the effect of simple structure, rapid and thorough discharge, and rapid heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

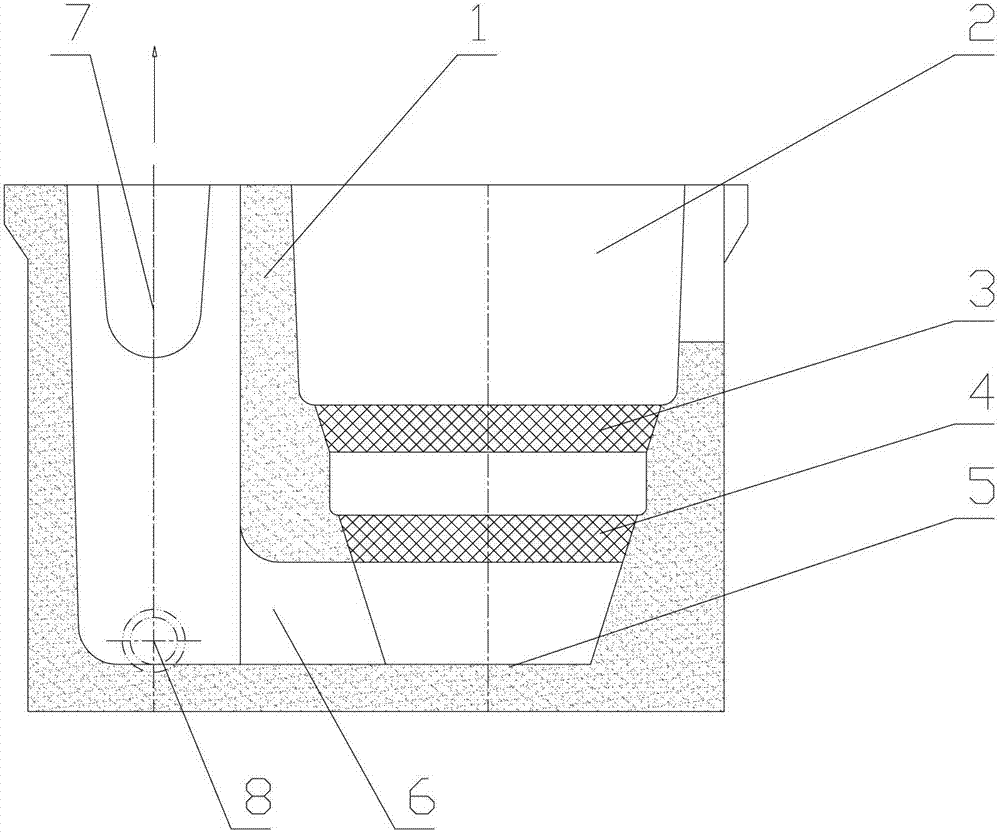

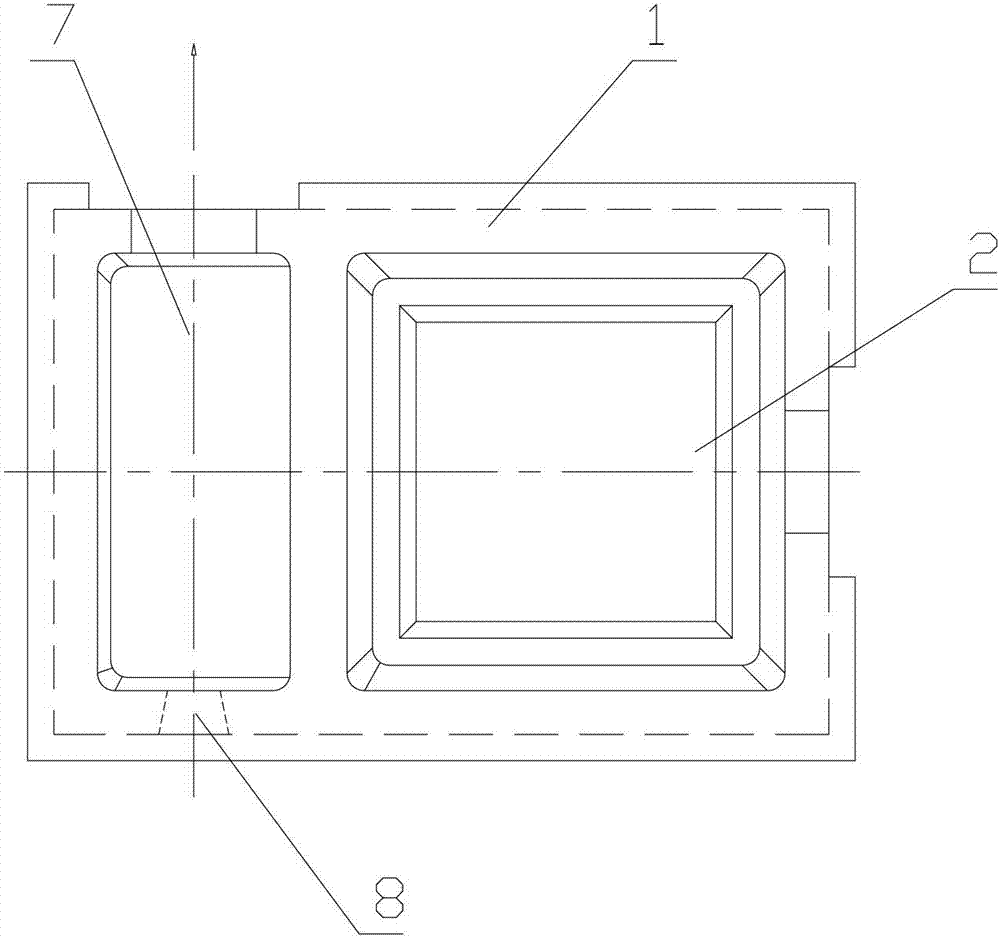

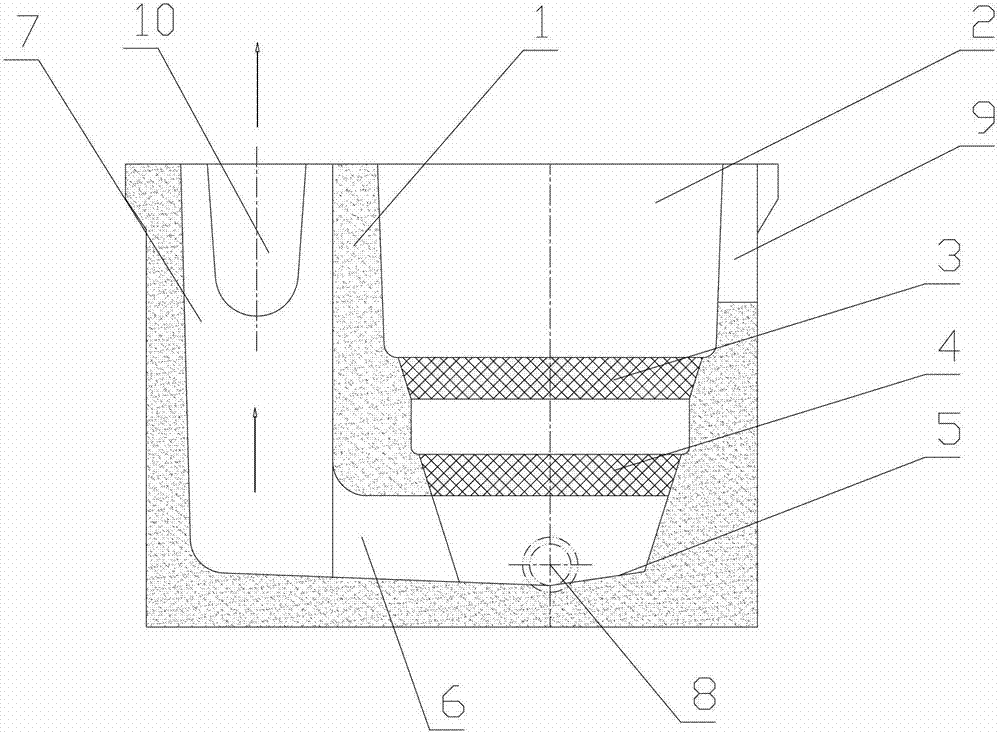

[0015] Such as Figure 3~4 As shown, the present invention mainly includes a box body 1, in which a liquid inlet chamber 2 and a liquid outlet chamber 7 are arranged, and the bottoms of the liquid inlet chamber 2 and the liquid outlet chamber 7 are communicated through a through hole 6. A coarse filter plate 3 and a fine filter plate 4 are sequentially installed in the liquid inlet chamber 2 from top to bottom, and a bypass hole 8 is provided on the bottom side of the liquid inlet chamber 2, through which the residual liquid in the box body 1 can be discharged , and at the same time, the direct baking of the fine filter plate 4 can be realized through the bypass hole 8 .

[0016] The inner box bottom 5 of the box body 1 is an inclined structure, and the height gradually decreases from the inner box bottom 5 to the bypass hole 8 . This structure is mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com