Device for manufacturing delta type hard alloy micro milling cutter

A technology of cemented carbide and micro-milling cutters, which is applied in the direction of attachments, manufacturing tools, electric processing equipment, etc., can solve problems such as low processing efficiency, material overcut, and difficult to guarantee processing accuracy, so as to improve processing efficiency and accelerate discharge Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

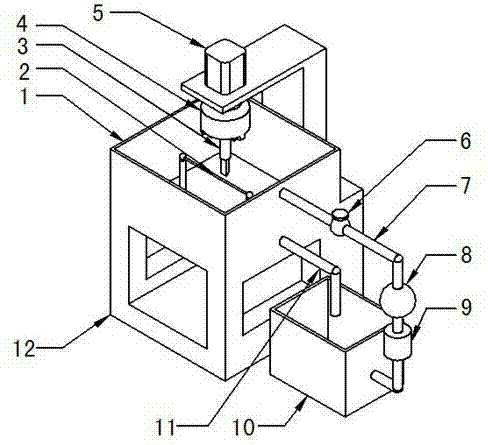

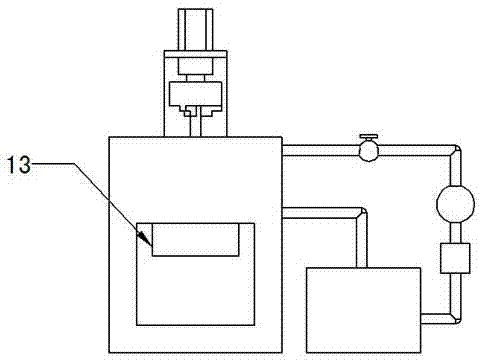

[0016] Such as figure 1 and 2 The device for preparing Δ-type cemented carbide micro-milling cutter combined with ultrasonic-assisted micro-electrolysis includes: electrolyte tank 1, tool electrode wire 2, Δ-type cemented carbide micro-milling cutter 3, tool holder 4, motor 5, Valve 6, electrolyte tank inlet pipe 7, pressure pump 8, filter 9, electrolyte storage tank 10, electrolyte tank drain pipe 11, workbench 12, ultrasonic auxiliary device 13, wherein, electrolyte tank 1 and The ultrasonic auxiliary device 13 is arranged on the workbench 12, the ultrasonic auxiliary device 13 is placed at the bottom of the electrolyte tank 1, the tool electrode wire 2 is placed in the electrolyte tank 1, and the Δ-type cemented carbide micro milling cutter 3 passes through the tool holder 4 and The motor 5 is connected, the electrolyte tank 1 and the electrolyte storage tank 10 are respectively connected through the electrolyte tank inlet pipe 7 and the electrolyte tank drain pipe 11, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com