Method for producing cylindrical fine tungsten wire electrode

A technology of cylinder and tungsten wire, which is applied in the direction of manufacturing tools, metal processing equipment, electrochemical processing equipment, etc., can solve the problems of slowing down the dissolution rate, affecting the efficiency and quality of fine tungsten wire electrodes, hindering the electrolytic reaction, etc., and achieving improvement The effect of efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

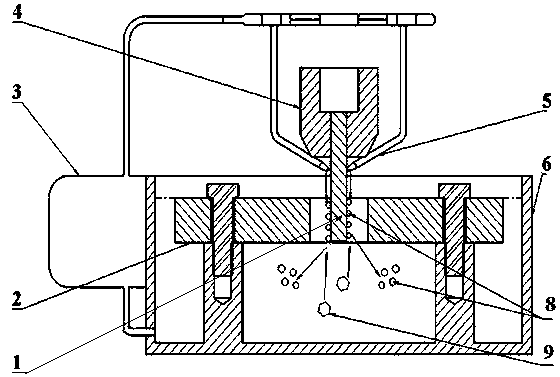

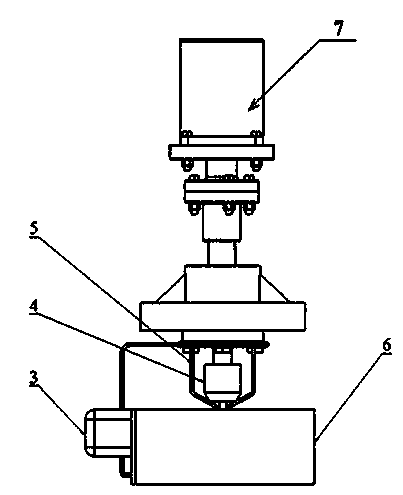

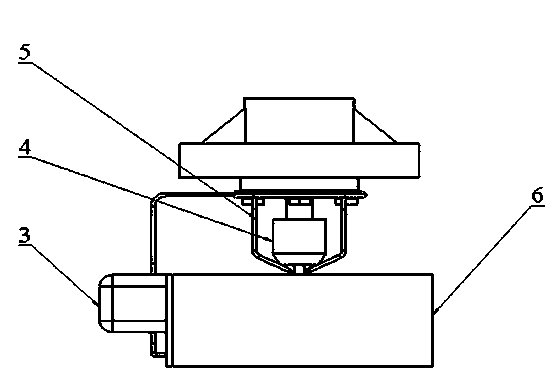

[0022] figure 1 , 2 3. The electrolytic device for preparing cylindrical fine tungsten wire electrode by assisting the impact of electrolyte shown in 3, which includes: tungsten wire electrode preparation material 1; stainless steel plate 2, fixed by positioning bolts, and used as cathode for tungsten wire electrode preparation material 1 after power on Carry out electrolytic processing; pressure pump 3 is used to extract the electrolyte and pass the electrolyte through the nozzle system 5 at a certain pressure along the rotating tungsten wire electrode preparation material 1 to impact the electrolytic processing area downward; clamp 4 is used for clamping and fixing Tungsten wire electrode preparation material 1; nozzle system 5, which includes 4 nozzles uniformly distributed at 90° to ensure that the electrolyte is sprayed at a certain flow rate against the tungsten wire electrode preparation material 1; electrolytic tank 6 provides an electrolytic processing place and perfo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com