Material spreading system of embossed plate processing equipment

A technology for processing equipment and laying materials, applied in the field of building materials manufacturing and processing, can solve problems such as high cost and low efficiency of embossed panels, and achieve the effect of reducing labor costs and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] A detailed description will be given below of specific embodiments of the present invention according to the accompanying drawings.

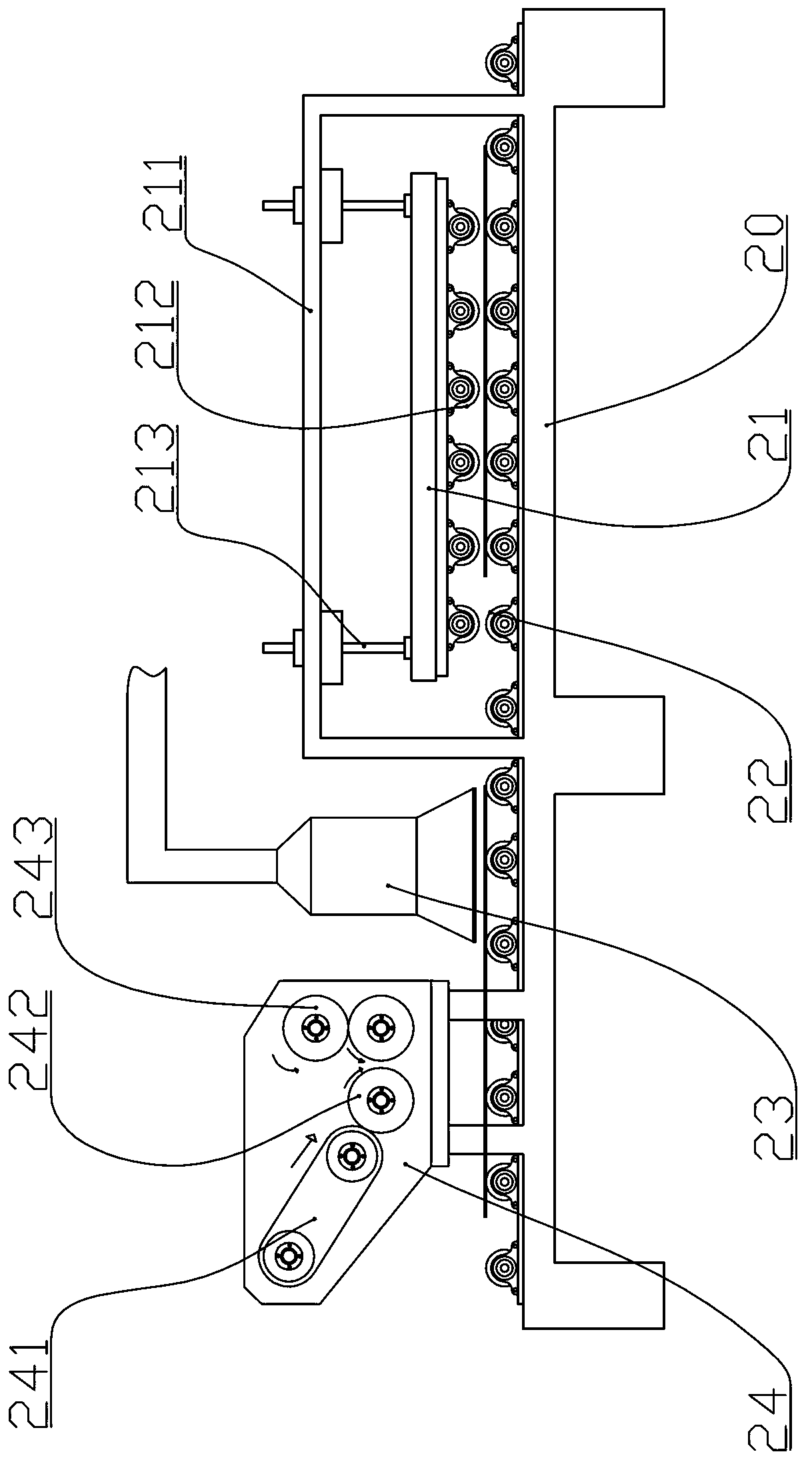

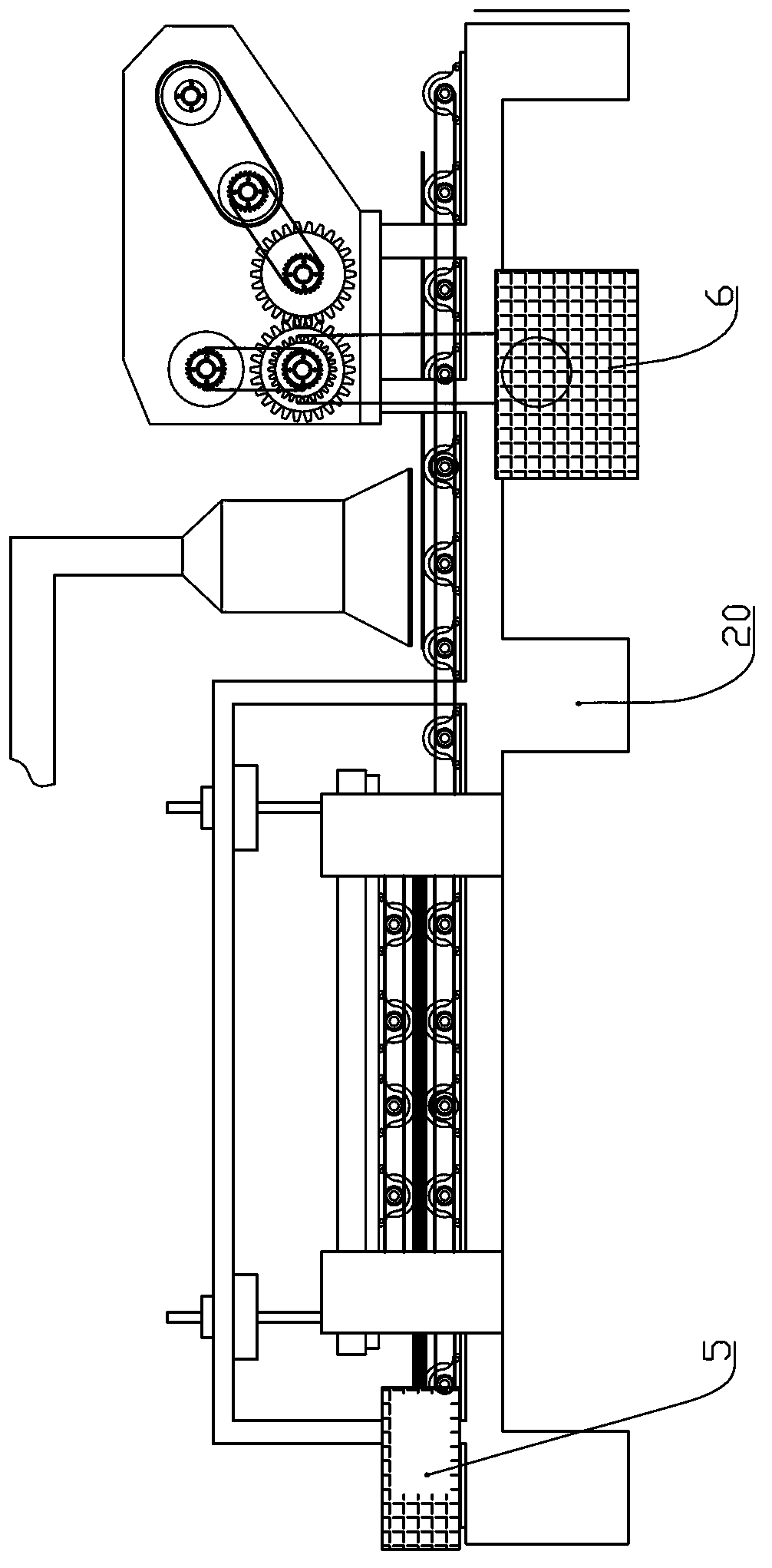

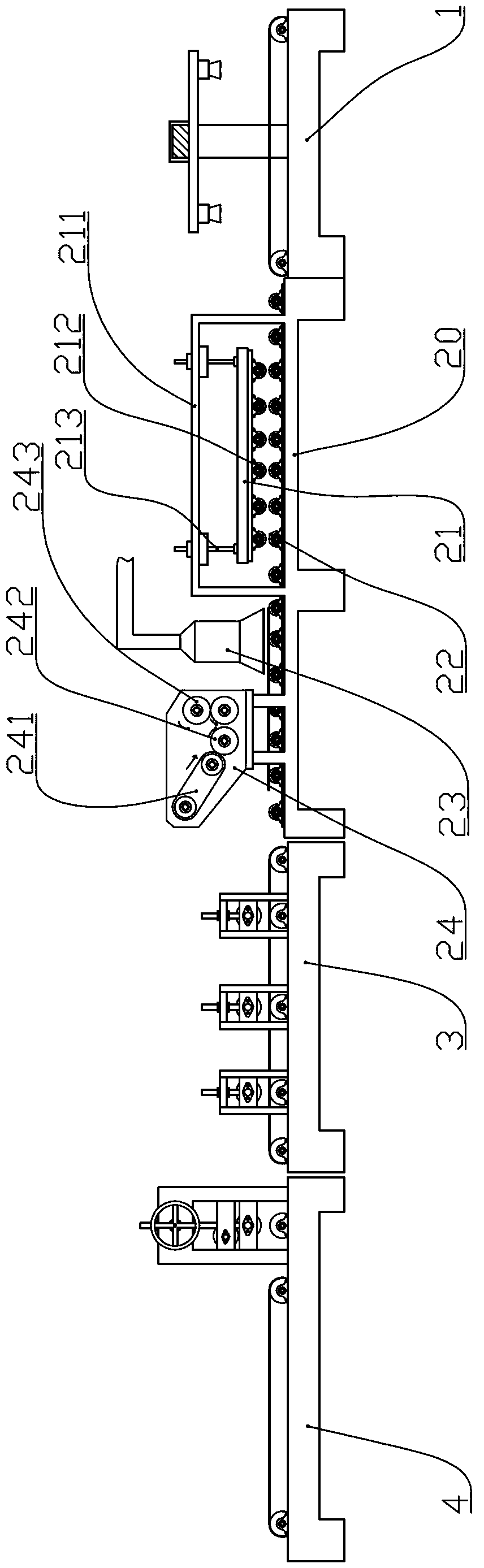

[0015] according to Figure 1 to Figure 3 As shown, the paving system of a kind of embossed plate processing equipment described in this embodiment includes a frame 20, a transmission roller group 22 installed horizontally on the frame 20, and fixedly installed on the frame 20 in turn and located at The pushing device 21, the dust suction device 23 and the discharging device 24 above the driving roller group 22, the discharging device 24 squeezes out the cloth-like printing molding material from below and lays it on the cement fiber substrate pushed by the driving roller group 22.

[0016] The outlet of the dust suction device 23 is connected to the filtering device arranged outside through a pipeline. The printing molding material is formulated from cement, pigments, adhesives and the like.

[0017] The drive roller set 22 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com