Method and equipment for refining sulfoxide chloride

A kind of technology of thionyl chloride and sulfone chloride, applied in the field of chemical technology production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

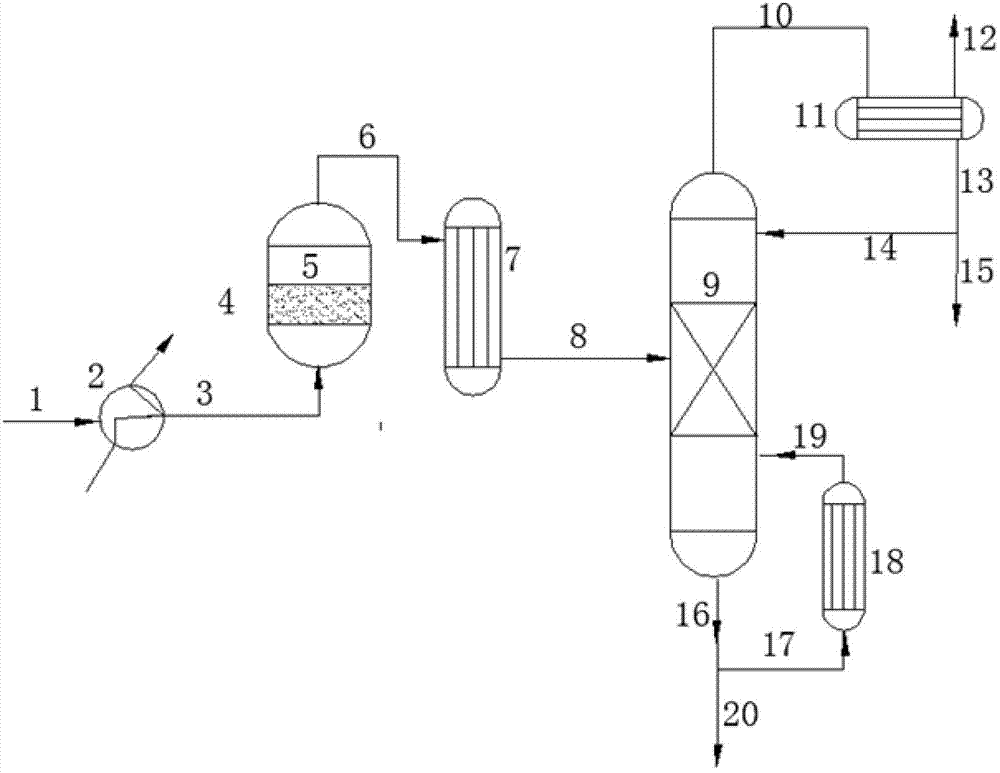

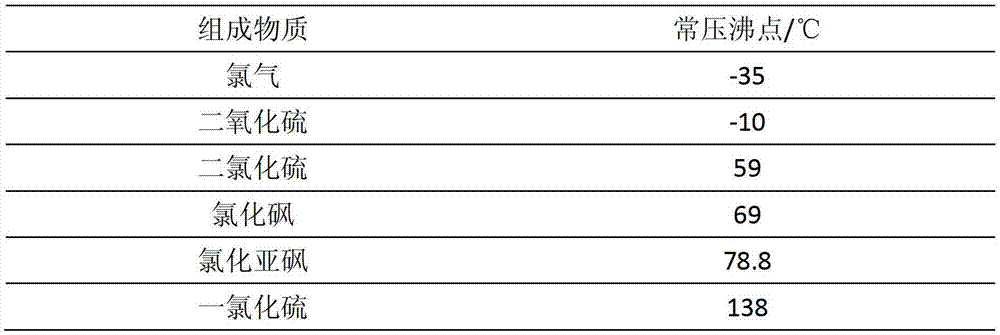

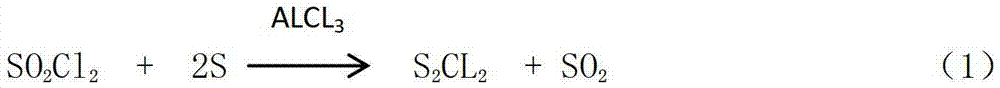

Method used

Image

Examples

Embodiment 1

[0029] Pass the saturated steam raw material containing 96% (mass fraction) of thionyl chloride and 4% thionyl chloride into the heater, heat it to 90°C, and then enter the fixed bed reactor. The activated carbon in the reactor is amorphous granular activity Carbon, to ensure that the residence time of the medium in the activated carbon is between 0.12-0.20 seconds, the decomposition reaction of sulfone chloride occurs (2), the conversion rate of sulfone chloride is above 95%, and the reacted gas enters the cooler to cool to saturation The liquid enters the rectification tower, the pressure inside the tower is normal pressure, the temperature at the top of the tower is -12°C, the temperature at the bottom of the tower is 76°C, and the molar reflux ratio is 5. The obtained product contains 99.8% of thionyl chloride and 0.2% of thionyl chloride %.

Embodiment 2

[0031] Pass saturated steam containing 95% of thionyl chloride and 5% of thionyl chloride into the heater, heat it to 95°C, and then enter the fixed bed reactor. The activated carbon in the reactor is amorphous granular activated carbon, ensuring that the medium is The residence time in the activated carbon is between 0.12-0.20 seconds, the decomposition reaction of sulfone chloride occurs (2), the conversion rate of sulfone chloride is above 95%, and the reacted gas enters the cooler to be cooled into a saturated liquid and enters the rectification tower Inside, the pressure inside the tower is normal pressure, the temperature at the top of the tower is -13°C, the temperature at the bottom of the tower is 76°C, and the molar reflux ratio is 6. The obtained product contains 99.8% of thionyl chloride and 0.2% of thionyl chloride.

Embodiment 3

[0033]Pass saturated steam containing 94% of thionyl chloride and 6% of thionyl chloride into the heater, heat to 100°C, and then enter the fixed-bed reactor. The activated carbon in the reactor is amorphous granular activated carbon, ensuring that the medium is The residence time in the activated carbon is between 0.12-0.20 seconds, the decomposition reaction of sulfone chloride occurs (2), the conversion rate of sulfone chloride is above 95%, and the reacted gas enters the cooler to be cooled into a saturated liquid and enters the rectification tower Inside, the pressure inside the tower is normal pressure, the temperature at the top of the tower is -14°C, the temperature at the bottom of the tower is 75°C, and the molar reflux ratio is 7. The obtained product contains 99.7% of thionyl chloride and 0.3% of thionyl chloride.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com