Method for catalyzing carbohydrate to prepare 5-(hydroxymethyl) furfural (5-HMF) and levulinic acid (LA)

A carbohydrate, hydroxymethyl furfural technology, applied in the preparation of organic compounds, chemical instruments and methods, preparation of carboxylate and other directions, can solve the problems of high energy consumption, high cost, difficult catalyst recovery and the like, and achieve high yield , low cost, large-scale industrialization prospects and the effect of strategic significance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

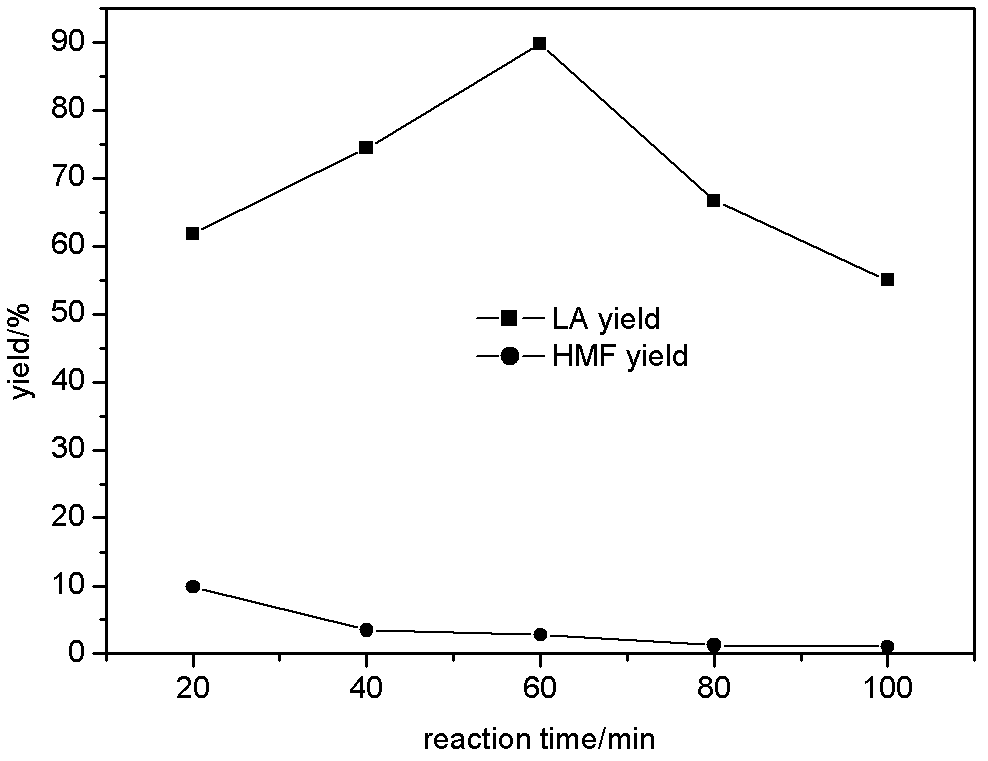

[0024] Dissolve 2.44g of ammonium metatungstate in 20ml of deionized water. After the ammonium metatungstate is completely dissolved, slowly add 5g of tantalum chloride to the ammonium metatungstate solution dropwise, stir at room temperature for 48 hours, and age for 12 hours. ℃ and 110℃ drying, 300℃ activation for 3 hours. The catalyst obtained above was used to catalyze the fructose reaction in a two-phase system composed of water and 2-butanol at 180 ° C, and the reaction liquid after removing the catalyst was detected by high performance liquid chromatography, and the yields of LA and HMF were 86% and 8% respectively .

Embodiment 2

[0026] Take 1.35g of metatungstic acid, dissolve it in water, add 5ml of tantalum ethoxide, stir at room temperature for 52h, let stand for aging for 12h, dry at 65°C, then put it in a vacuum drying oven at 110°C for 2h, then slowly raise the temperature to 300°C in a muffle furnace After activation at ℃ for 3 hours, the desired catalyst can be obtained, which is a tungsten-tantalum catalyst.

[0027] Take 0.01g of the above catalyst (5% tungsten trioxide content), 1.2g of glucose, add 20ml of water and 30ml of methyl isobutyl ketone, seal, react at 160°C for 30min, filter the reaction solution to separate the catalyst, remove the catalyst The reaction solution was detected by high performance liquid chromatography, and the yields of LA and HMF were measured to be 85% and 8%.

Embodiment 3

[0029] Take 1g of tungsten chloride and dissolve it in water. After it dissolves, add 5g of tantalum hydroxide, continue to stir at room temperature for 4h, let it stand for aging for 12h, wash it with water until it does not contain chloride ions, and dry the obtained precipitate at 60°C for 2h. It can be activated and roasted at ℃. The catalysts were characterized and verified by XPS.

[0030] Get this catalyst 0.1g, fructose 2g, add water 20ml, butanol 30ml, 160 ℃ of reaction 60min, reaction solution is filtered to separate catalyst, sample is detected by high performance liquid chromatography, record LA and HMF yield is 69% and 17%. %.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com