Roller dryer with knocking hammer

A drum dryer and percussion hammer technology, applied in non-progressive dryers, dryers, drying solid materials, etc., can solve the problems of low production efficiency, easy to stick into blocks, and the drying temperature cannot be too high, and achieve Improve drying efficiency and reduce moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific embodiments, structures, features, and effects of the present invention will be described in detail below with reference to the accompanying drawings and preferred embodiments.

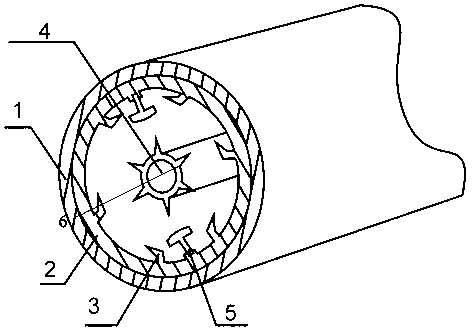

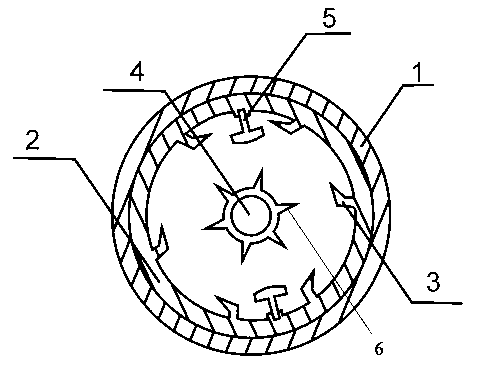

[0014] Such as Figure 1~2 The drum dryer with percussion hammer shown includes a cylindrical shell and an inner ring. The inner shell of the cylindrical shell 1 is covered with an inner ring 2, and the inner wall of the inner ring is respectively provided with a number of dispersing knives 3 and a set For the breaking hammer 5, the center part of the inner cavity of the inner ring is equipped with a disperser 4, and the outer periphery of the disperser is provided with a number of dispersing teeth 6

[0015] In the specific implementation process, preferably, the number of dispersing teeth provided on the outer circumference of the disperser 4 can be adjusted according to actual needs, and the shape can also be changed according to the type of material that is actually dried, such as k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com