Deep hole blasting method

A deep hole blasting and deep hole technology, applied in the field of deep hole blasting, can solve problems such as potential safety hazards, and achieve the effect of high mining blasting efficiency and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

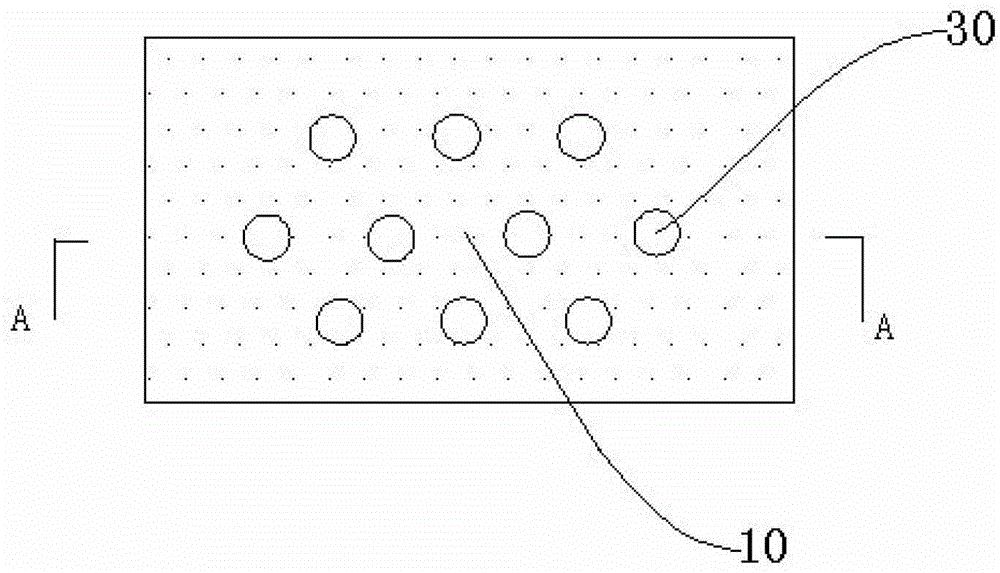

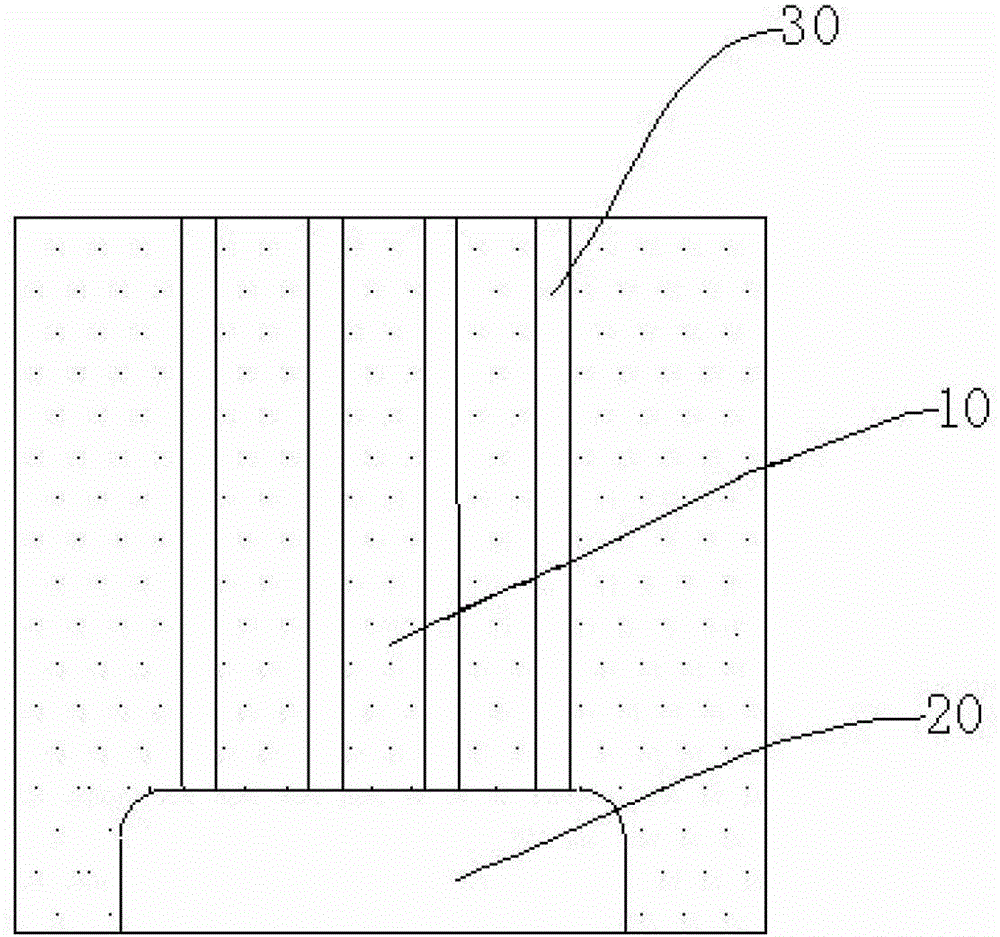

[0026] see figure 1 and figure 2 , the embodiment of the present invention provides a kind of deep hole blasting method, is used for the horizontal ore pillar 10 that has empty area 20 below to carry out mining, comprises the following steps: Step S1: on the upper surface of the horizontal ore pillar 10 of preparation blasting downwards Drilling a plurality of vertical deep holes 30, a plurality of deep holes 30 form a deep hole bundle, and each deep hole 30 is connected to the empty space 20; step S2: each deep hole 30 is filled with strip explosives from bottom to top; step S3 : take the lower free surface of the horizontal ore pillar 10 as the blasting free surface, take the empty area 20 as the blasting ore falling area, and the strip explosiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com