Method and device for detecting defect in matrix

A technology of internal defects and matrix, which is applied in the direction of measuring devices, optical testing flaws/defects, scattering characteristics measurement, etc., can solve the problems of low accuracy rate, inability to effectively distinguish the type of defects, and low resolution, so as to improve the accuracy rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0081] At present, human eyes are usually used to determine whether the defect is located inside or on the surface of the matrix (especially glass). If it is located on the surface, the type of defect can be determined by hand touch; however, the accuracy of this manual detection is low and cannot be distinguished. Type and location of defects within the matrix. In order to solve the above problems, automatic optical inspection (AOI) technology was subsequently developed, which can place a light source under the substrate, set up two image capture devices above the substrate, and obtain the position of the defect by triangulation; but this method also cannot Good for determining the type of defect.

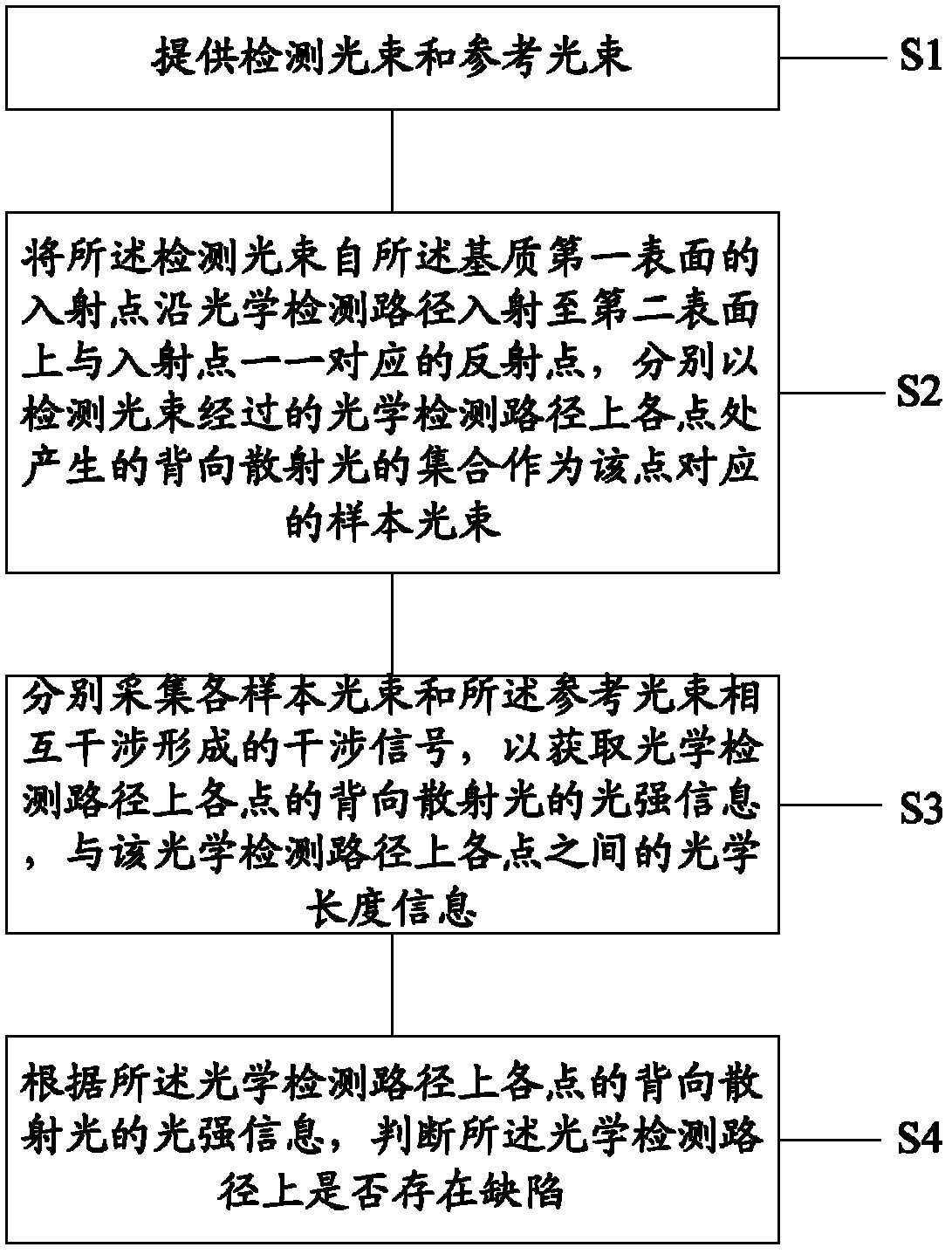

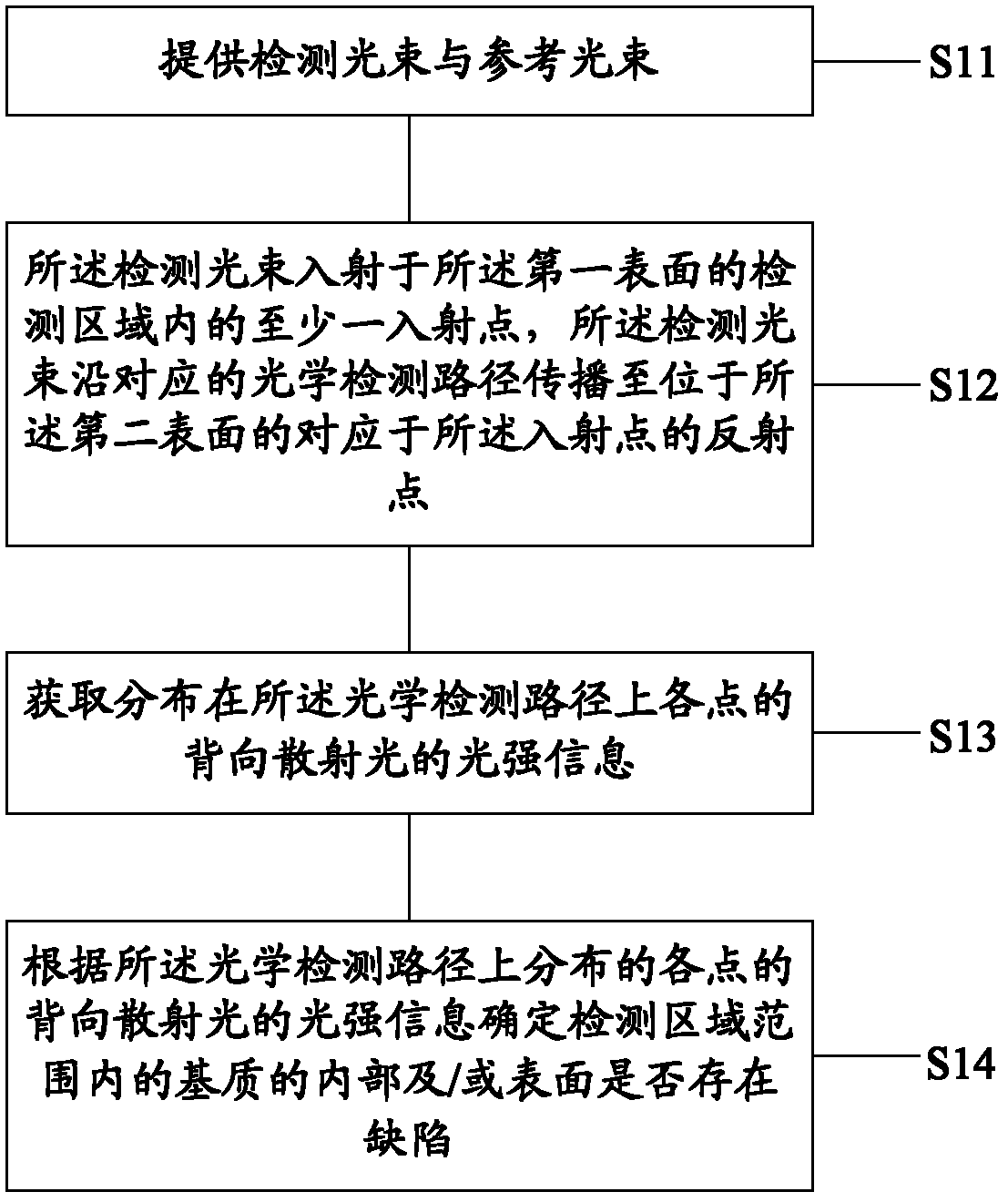

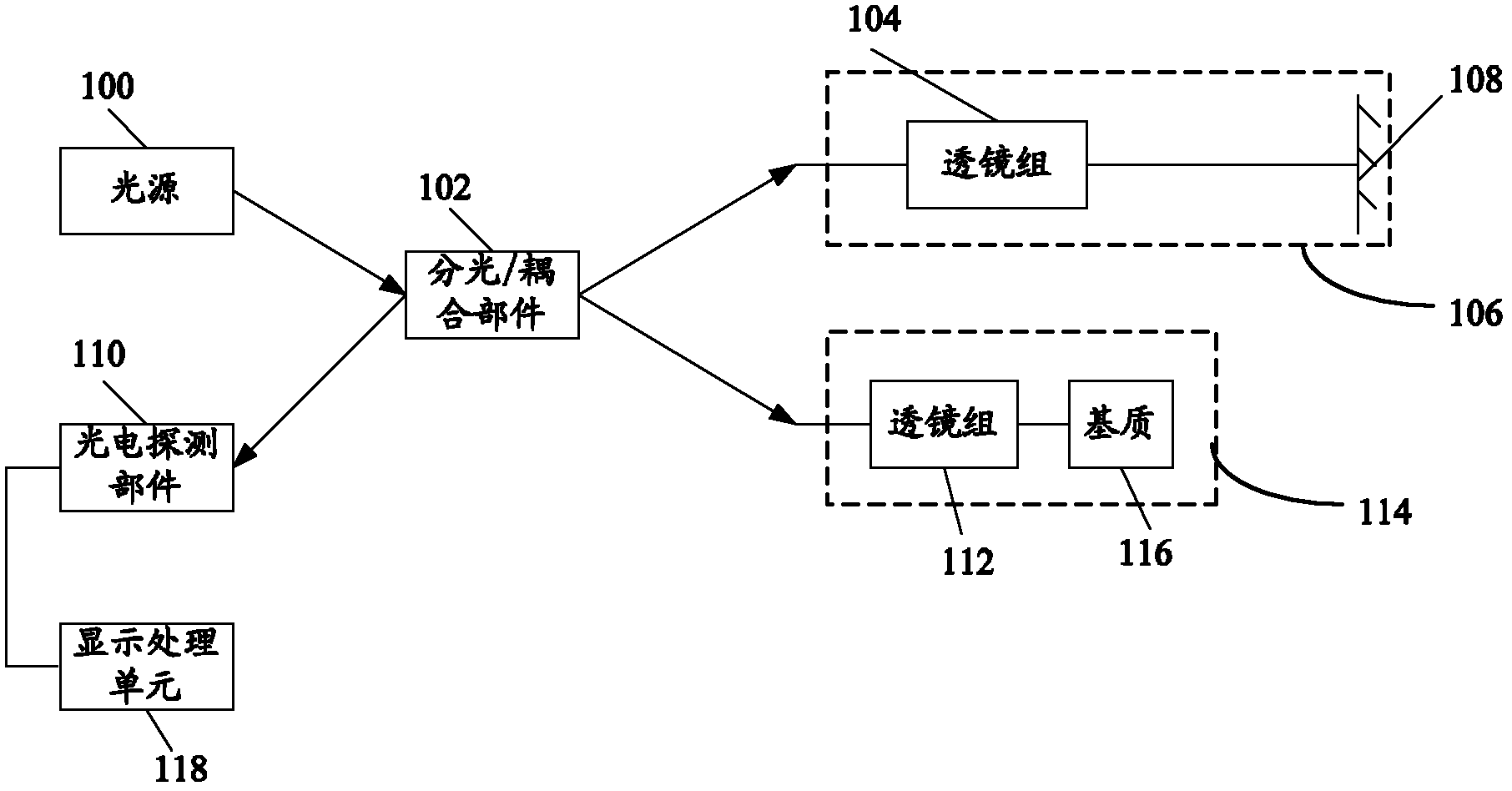

[0082] After research, the inventors found a method for detecting defects in a matrix. The matrix has opposite first and second surfaces, and a plurality of incident points are distributed on the first surface. The detection steps are as follows: figure 1 shown, including:

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resolution | aaaaa | aaaaa |

| Resolution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com