Lens linear actuator and assembly technology thereof

A linear driver and driver technology, applied in the direction of installation, instruments, electromechanical devices, etc., can solve the problems of increased production costs, inconsistent optical axes, etc., and achieve the effects of easy mass production, fewer parts, and simple assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] This embodiment is a preferred embodiment of the present invention, and other principles and basic structures that are the same as or similar to those of this embodiment fall within the protection scope of the present invention.

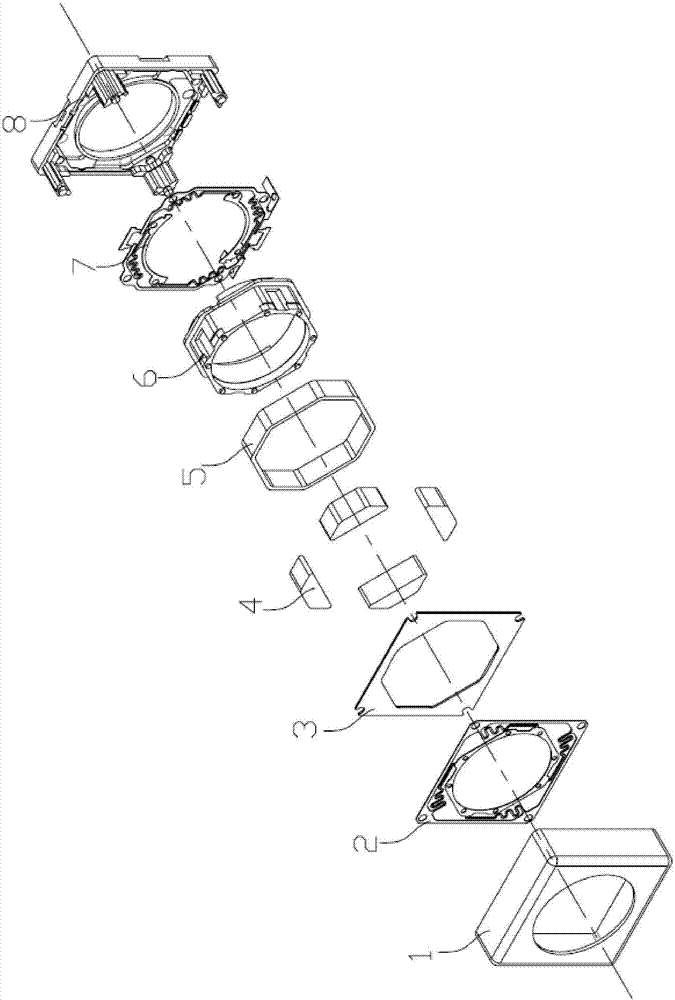

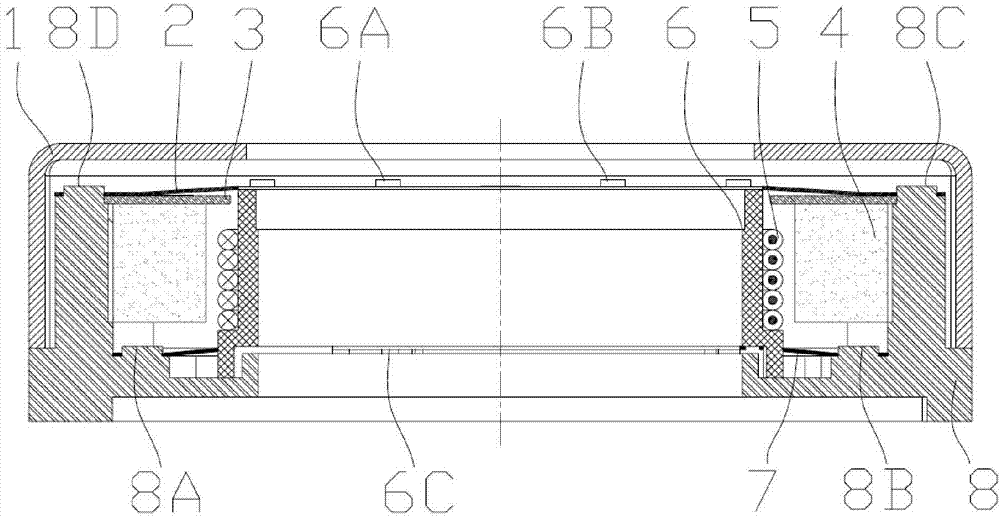

[0027] Please refer to the attached figure 1 And figure 2 , The present invention is mainly a lens linear driver structure that can control the tilt or translation of the lens. Its main body is the driver fixing bracket 8. The bottom of the driver fixing bracket 8 is square and the same as the cross section of the lens driver. The four corners of the driver fixing bracket 8 are respectively A supporting rod extending upward is provided, and the four supporting rods form an accommodating cavity. The four corners inside the accommodating cavity are respectively provided with a lower plane spring positioning column extending upwards. In this embodiment, only the drawing Two, respectively, the second lower plane spring positioning post 8A and the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com