Liquid crystal module

A technology of liquid crystal modules and LED light strips, which is applied in the direction of lighting and heating equipment, instruments, mechanical equipment, etc., can solve the problems of increasing manufacturing costs, achieve the effects of increasing manufacturing costs, high practicability, and solving light leakage on the light incident side

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

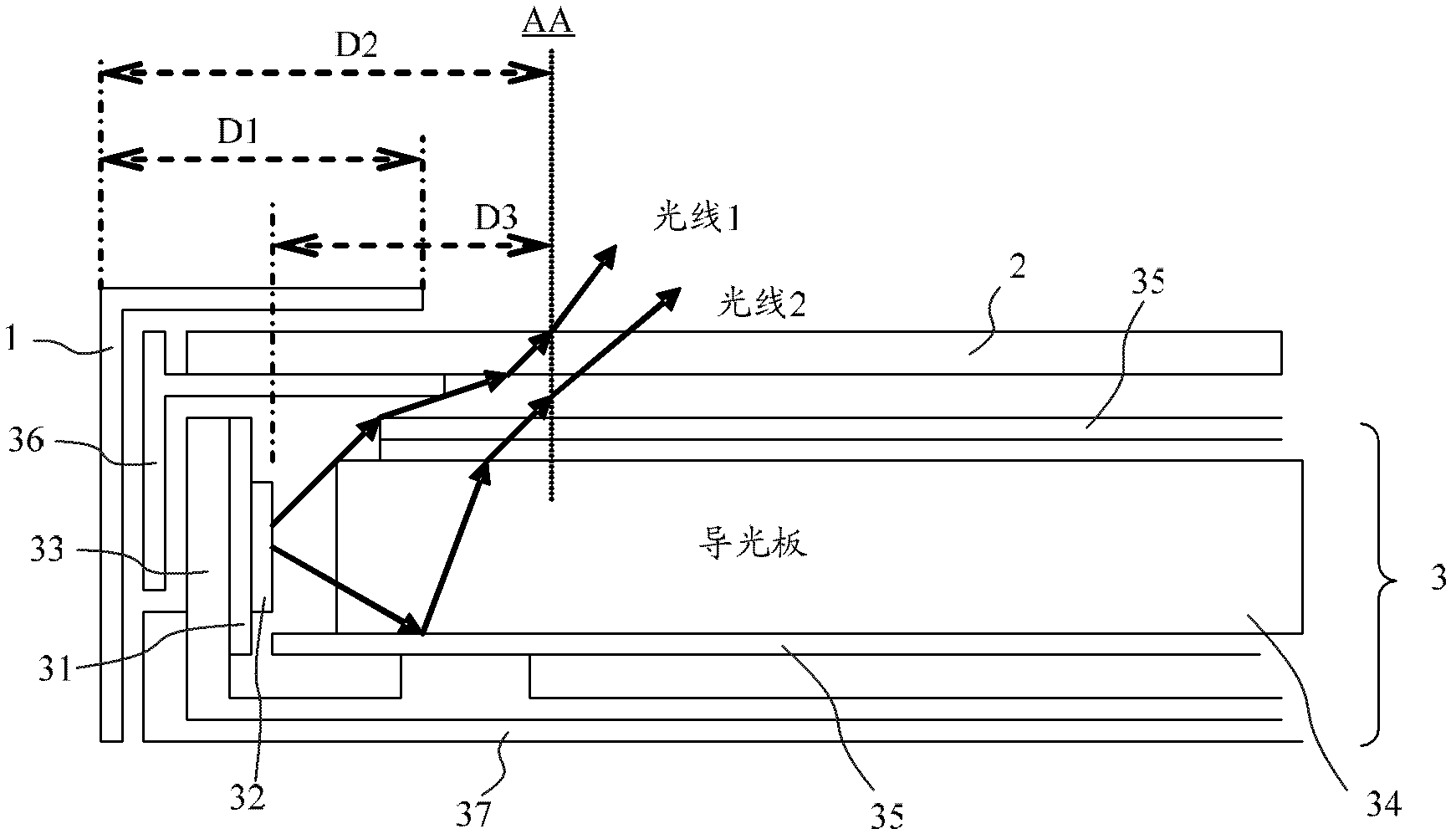

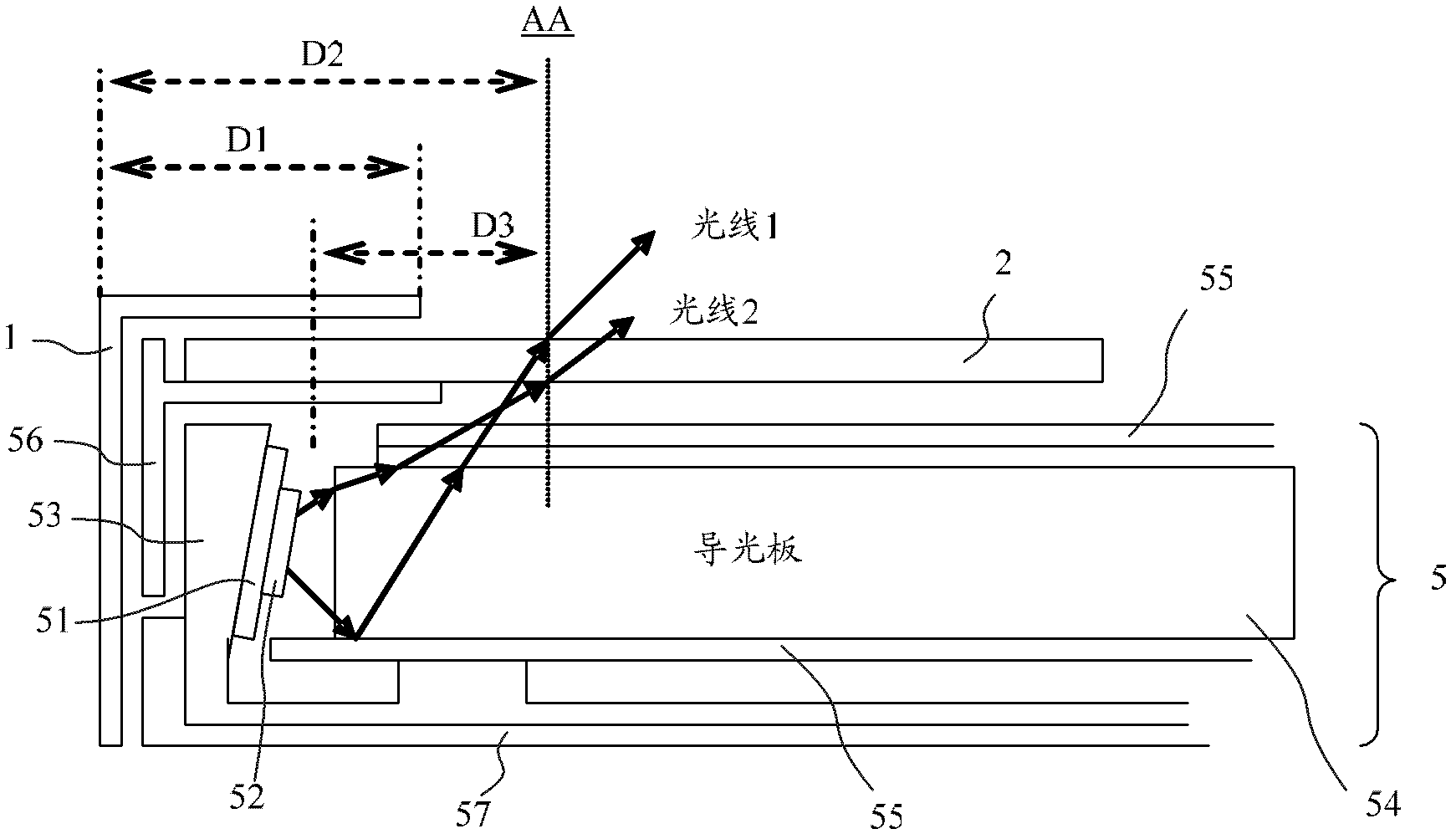

[0024] Such as figure 2 As shown, this embodiment provides a liquid crystal module, including: a metal front frame 1 , a liquid crystal panel 2 and a backlight module 5 .

[0025] Wherein, the backlight module 5 is a side-entry LED backlight module, including an LED light strip 51, an LED light 52 placed on the LED light strip, a heat sink 53 for dissipating heat from the LED light strip, a light guide plate 54, The optical film 55 placed above the light guide plate to reflect light, the plastic frame 56 to support the liquid crystal panel 2 and the back plate 57 to fix and support the components in the backlight module. The LED light bar 52 installed with the LED light 52 is called an LED light bar. The heat sink 33 is installed on the back of the LED light bar, and the LED light bar is placed around or on both sides of the light guide plate 34 .

[0026] In this embodiment, the angle α between the LED light on the LED light bar and the bottom plane of the light guide plat...

Embodiment 2

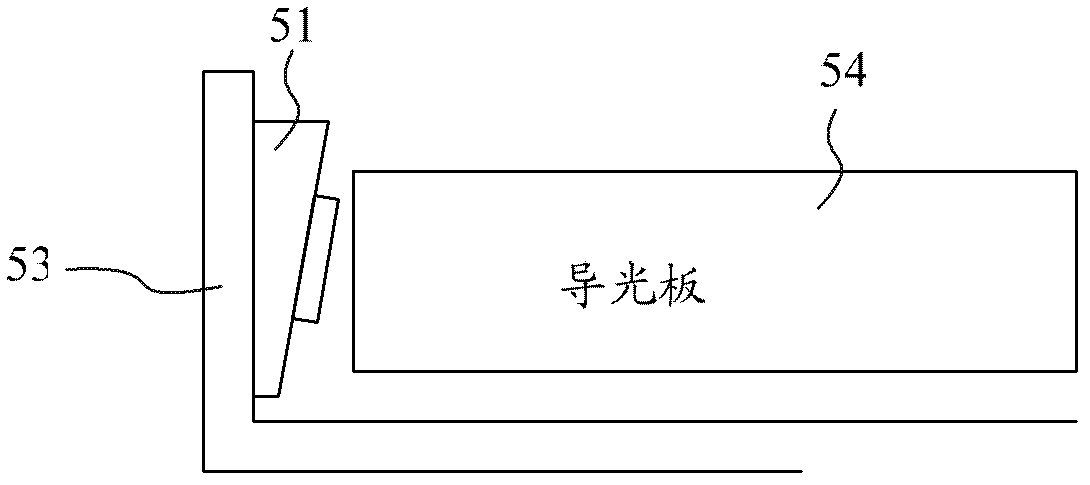

[0029] Such as image 3 As shown, the difference from Embodiment 1 is that in this embodiment, the LED light strip 51 is changed into a wedge-shaped structure, and the wedge-shaped structure can be realized by changing the thickness of the aluminum substrate on the LED light strip 51, that is, the LED The thickness of the aluminum substrate on the light strip 51 is processed into a wedge-shaped structure.

Embodiment 3

[0031] Such as Figure 4 As shown, the difference from Embodiment 1 is that in this embodiment, the distance between the LED light on the LED light bar and the bottom plane of the light guide plate is realized by adjusting the thickness of the adhesive coating 58 on which the heat sink adheres to the LED light bar. The angle between them is less than 90 degrees. That is, by making the thickness of the adhesive coating uneven, the angle between the LED light on the LED light bar and the bottom plane of the light guide plate can be less than 90 degrees.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com