New electrical control cabinet

An electrical control cabinet, a new type of technology, applied in the direction of electrical equipment shell/cabinet/drawer, electrical components, cooling/ventilation/heating renovation, etc., can solve the problem of heavy dust removal maintenance workload, unsatisfactory cooling effect, low equipment reliability problems, to achieve the effect of saving energy consumption, reducing working environment requirements, and convenient application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

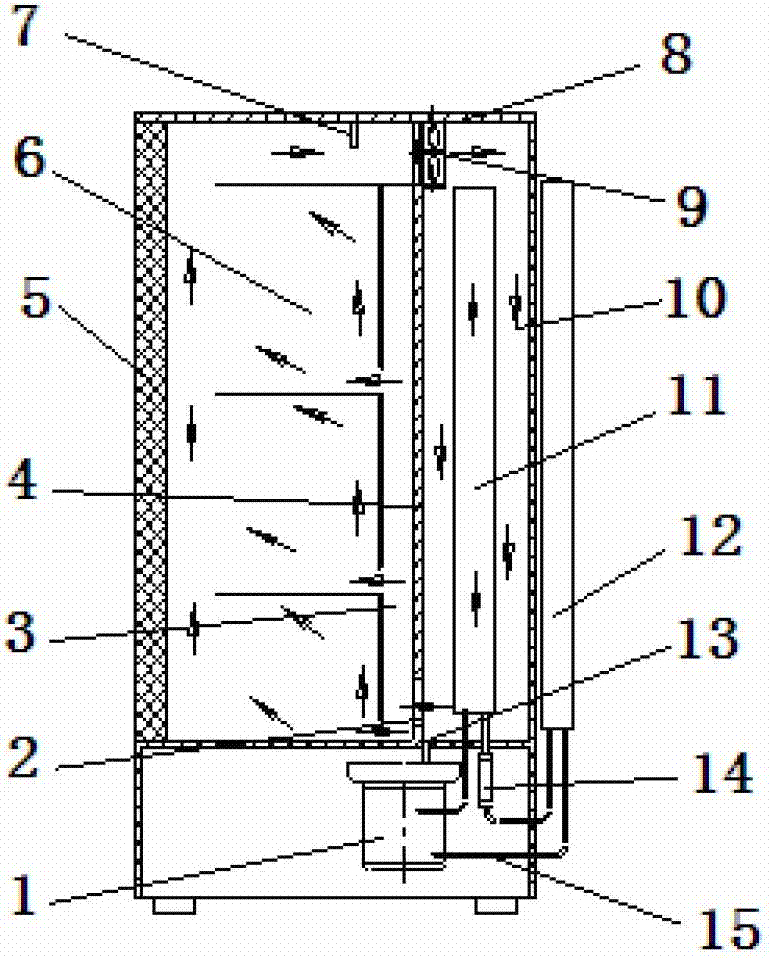

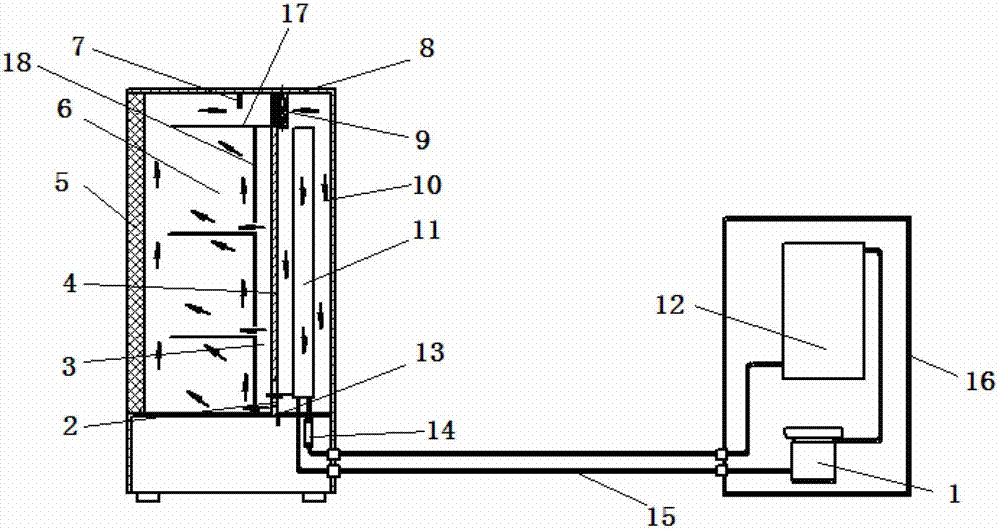

[0020] refer to figure 1 with figure 2 , a new type of electrical control cabinet, including a cabinet door 5 and a cabinet body 8, the cabinet body 8 has a closed structure, and a partition 4 is vertically provided in the cabinet body 8, and the partition board 4 separates the cabinet body 8 The internal space is divided into the equipment working area 6 and the medium cooling and drying area 10; the upper end of the partition 4 is equipped with an internal circulation fan 9, and the air flow direction flows from the equipment working area 6 to the medium cooling and drying area 10, and the bottom of the partition 4 A cold air inlet 2 is provided; a heat dissipation assembly 12 is provided on the outer wall of the cabinet body 8 close to the side of the medium cooling and drying area 10, and a heat absorbing assembly 11 is arranged in the medium cooling and drying area 10, and the heat absorbing assembly 11 is connected to the compressor 1 through the connecting pipeline 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com