Cotton and polyester bunchy heterochromatic interwoven fabric and processing process thereof

A processing technology, cotton, polyester and bamboo technology, applied in the direction of fabric surface trimming, weaving, fabric, etc., to achieve the effect of increasing fabric strength, good quality, and improving wrinkle resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in conjunction with embodiment.

[0051] 1. Product Design

[0052] 1. Design points

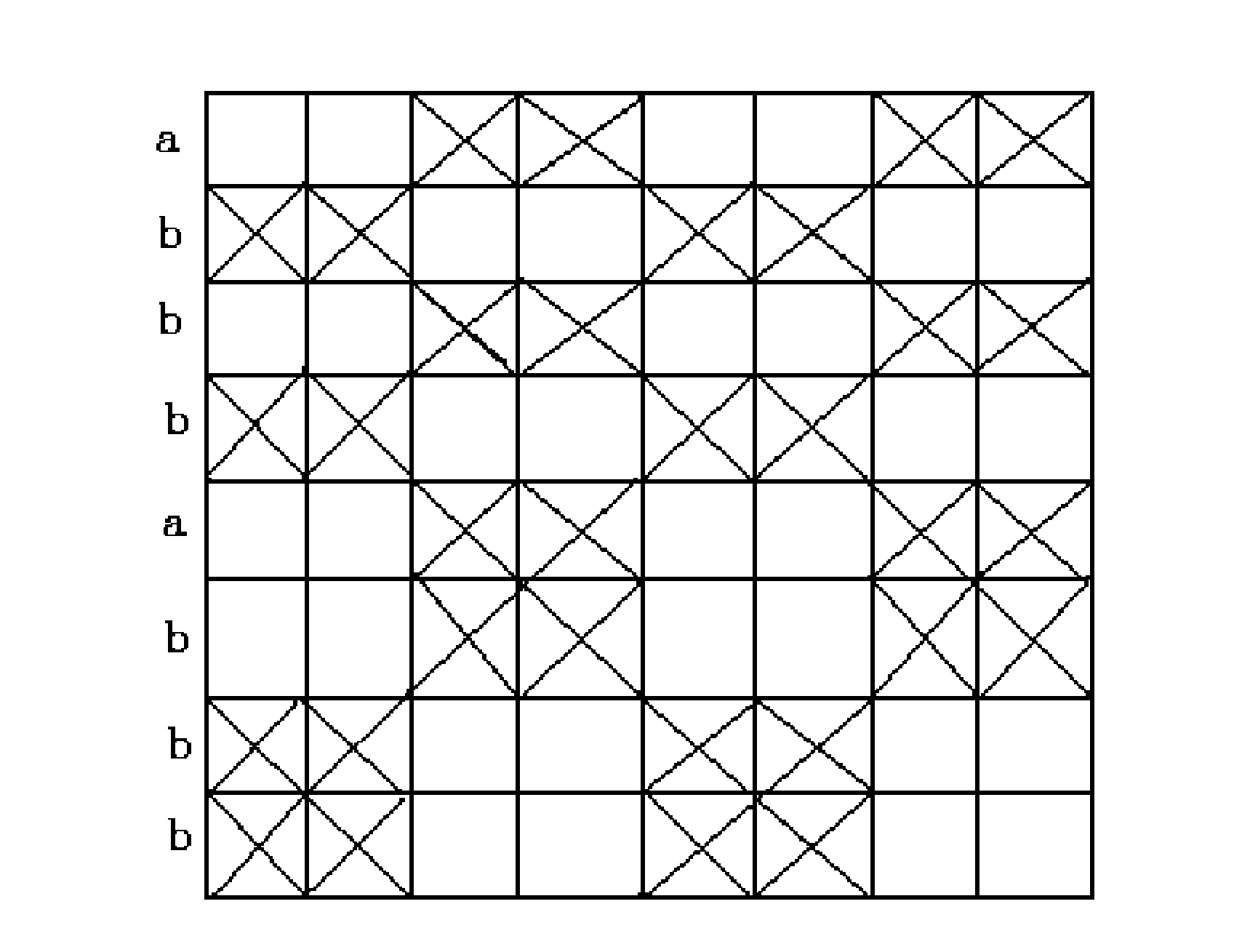

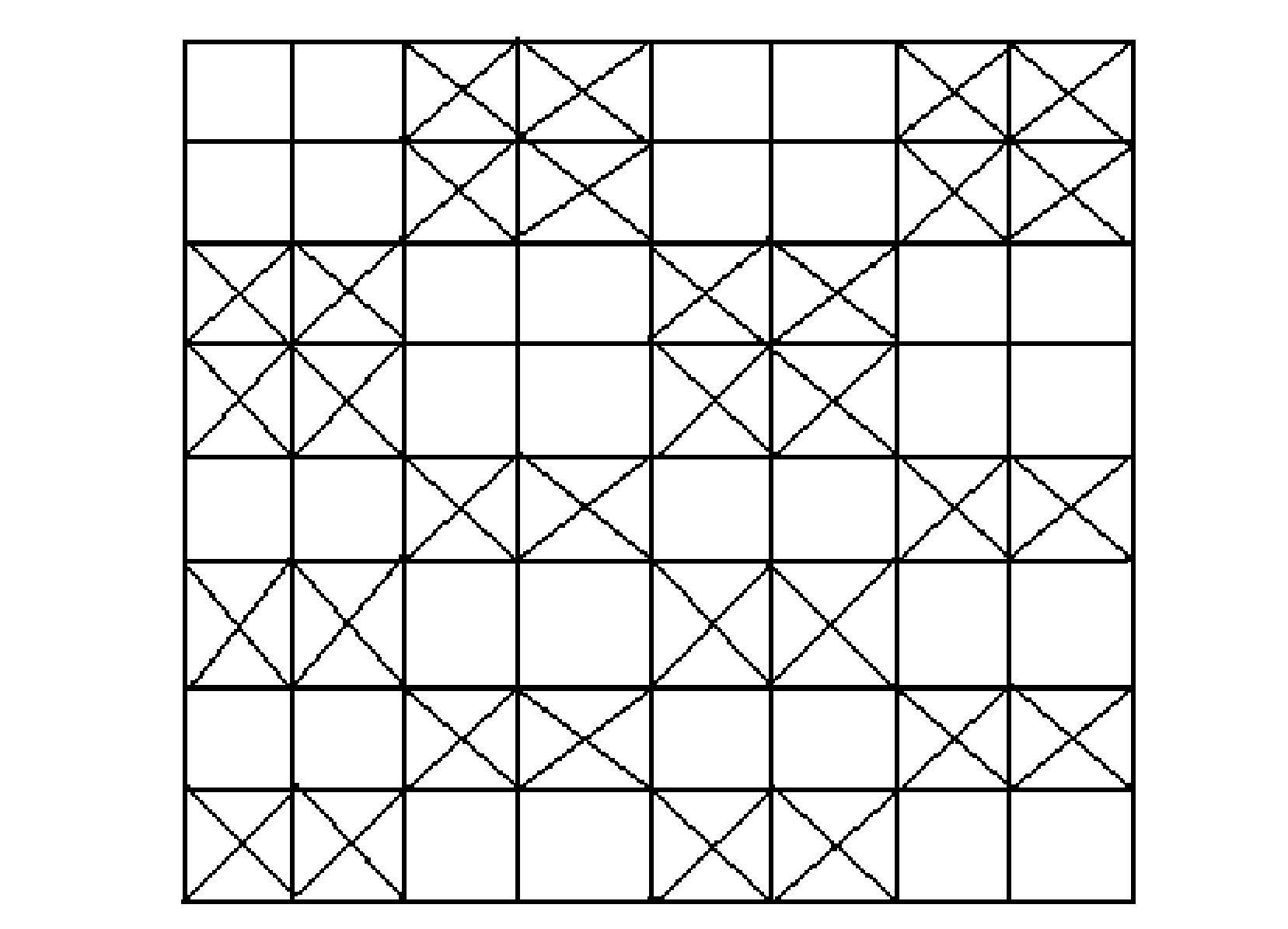

[0053] The design of this product is mainly used to make spring and autumn trouser fabrics. Using the different dyeing properties of pure cotton fiber and pure polyester fiber, the finished product has the effect of different colors, faint and delicate, natural, comfortable and wrinkle-resistant. Based on this design purpose, the overall design is based on pure cotton high-count yarn, and high-density weaving is adopted to make the cloth surface delicate and soft to the touch. The weft direction is interwoven with pure cotton yarn and pure polyester yarn, which can be more Good for highlighting the heterochromatic effect of dyeing. However, considering the use of plain yarns made of two raw materials, the texture of the cloth surface is not good and lacks natural and vivid effects. Therefore, pure cotton slub yarn and pure polyes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com